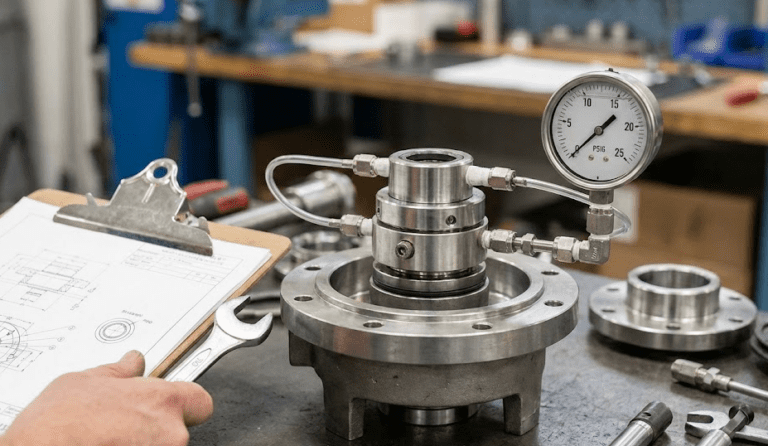

You pull a failed seal from a pump and find the stationary seat cracked. The replacement needs to match – but which material is this? Seal-related repairs represent 60-70% of all centrifugal pump maintenance work, and installing the wrong seat material turns a simple replacement into repeat failure.

This guide covers visual identification techniques, physical tests, material properties, and mounting type selection. By the end, you’ll identify unknown seats with confidence and select correct replacements for your application.

Common Seat Materials and Their Characteristics

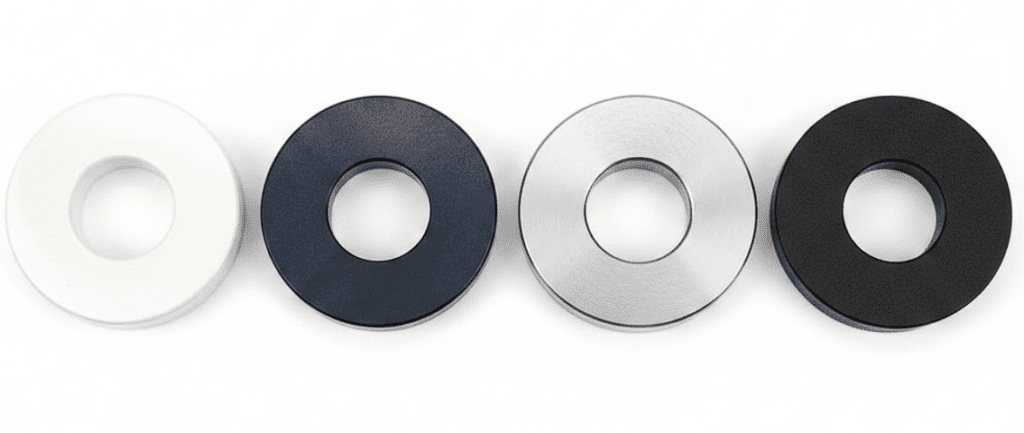

Four materials dominate mechanical seal seats: ceramic (alumina), silicon carbide, tungsten carbide, and carbon graphite. Each has distinct visual and physical properties that enable field identification.

Ceramic (Alumina) consists of 99.5% aluminum oxide. It appears white, cream, or off-white – the only common seat material with this distinctive light color. Ceramic seats are lightweight and smooth to the touch.

Silicon Carbide is a bluish-black material created by fusing silica and coke. The dark coloration sets it apart from ceramic’s white appearance. SiC feels similar in weight to ceramic despite having very different properties.

Tungsten Carbide has a silvery-gray metallic appearance. The critical identifier is weight – tungsten carbide is much heavier than any other seal face material. Pick up two similar-sized seats; if one feels like you’re holding a fishing sinker, that’s tungsten carbide.

Carbon Graphite appears black or dark gray with a softer, almost waxy surface texture. It’s the lightest seat material and may show visible wear patterns or slight porosity on used examples.

Field Identification Methods

Catalog images don’t help when you’re standing in a pump room with an unknown seat. These three tests work without specialized equipment.

Visual Identification by Color

Color is your first filter. Under decent lighting:

| Material | Color/Appearance | Distinguishing Feature |

|---|---|---|

| Ceramic | White/cream/off-white | Only white seat material |

| Silicon Carbide | Bluish-black | Dark with slight blue tint |

| Tungsten Carbide | Silvery-gray metallic | Metallic sheen |

| Carbon Graphite | Black/dark gray | Matte finish, may show porosity |

White means ceramic. Dark means carbide (silicon or tungsten) or carbon. Metallic gray with shine suggests tungsten carbide.

Weight Test (The Fastest Method)

The weight test takes two seconds and is right 95% of the time.

Tungsten carbide has a density of approximately 15.6 g/cm3. Silicon carbide sits at about 3.2 g/cm3. That’s nearly a 5:1 ratio. As industry consensus confirms, “tungsten carbide is very hard like silicon carbide however it is very heavy to the touch, making it easy to distinguish from silicon carbide.”

Hold two similar-sized seats, one in each hand. If one feels much heavier – like comparing aluminum to lead – that’s tungsten carbide. Silicon carbide and ceramic feel similar in weight. Carbon graphite is the lightest of all.

For single unknowns, compare against a seat of known material or simply note whether the weight seems excessive for the size. Tungsten carbide’s heft is unmistakable.

Magnet Test for Metal-Bound Materials

A pocket magnet adds another data point. Nickel-bound tungsten carbide responds to magnets. Pure silicon carbide and ceramic do not.

Note that some tungsten carbide seats use cobalt binders instead of nickel. Cobalt-bound WC is less magnetic. A negative magnet test doesn’t rule out tungsten carbide – confirm with the weight test.

Ni-Resist and 17-4 PH stainless steel seats (less common) also respond to magnets. These metallic seats have obvious machined metal appearance that sets them apart from the ceramic materials.

Seat Mounting Types

Mounting configuration also affects replacement selection and performance.

Cup Mount (Elastomer Boot): The seat presses into an elastomer boot that grips the seal housing bore. Installation takes seconds. Cup mounts forgive bore imperfections – they work with surface finishes up to 63 RMS where O-ring seats would leak.

O-Ring Mount: The seat sits in a metal holder with O-ring secondary seals. O-ring mounts handle pressures up to 600 psi. The solid metal construction provides better heat dissipation than elastomer boots.

Cup mounts forgive bad bores; O-ring mounts handle the pressure. For field repairs where bore condition is questionable, cup mounts are more forgiving. For high-pressure applications or where heat dissipation matters, O-ring mounts perform better.

Type 1 and Type 3 seats are often interchangeable per DMR specifications. Check your seal manufacturer’s documentation for confirmed interchanges.

Putting Identification Into Practice

Start with visual color to narrow the field. Confirm with the weight test – that 5:1 density ratio between tungsten and silicon carbide is unmistakable in your hand. Use the magnet test as a third check for nickel-bound materials.

For documentation, reference API 682 material codes:

- Code N: Carbon vs reaction-bonded silicon carbide

- Code M: Carbon vs nickel-bound tungsten carbide

- Code P: Reaction-bonded SiC vs reaction-bonded SiC

- Code Q: Sintered SiC vs sintered SiC

When you cannot positively identify a seat – particularly when distinguishing silicon carbide grades or unusual materials – contact the seal manufacturer with photos and dimensions. The API 682 standard specifies this for a reason: guessing wrong costs more than a phone call.

Document what you find. Note the material, mounting type, and application conditions. The next technician troubleshooting this pump will thank you.