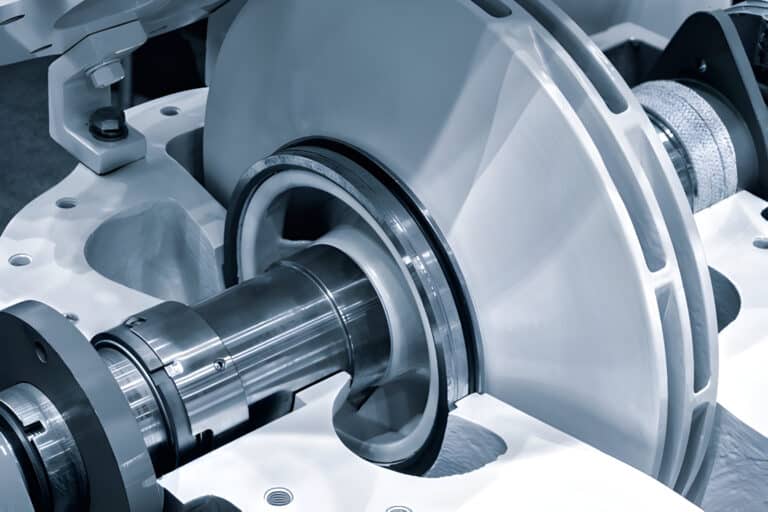

Mechanical seals consist of two critical components working together: a primary seal created by a hydrodynamic film between two seal faces, and a secondary seal formed by elastomers like O-rings. The material you choose for those seal faces determines everything—friction levels, wear rates, chemical resistance, and how long your seal actually lasts.

Think of it this way: you wouldn’t use the same roofing material in Alaska and Arizona. Climate demands different solutions. Same principle applies to seals. Your application fluid, temperature, pressure, and operating conditions demand specific material combinations.

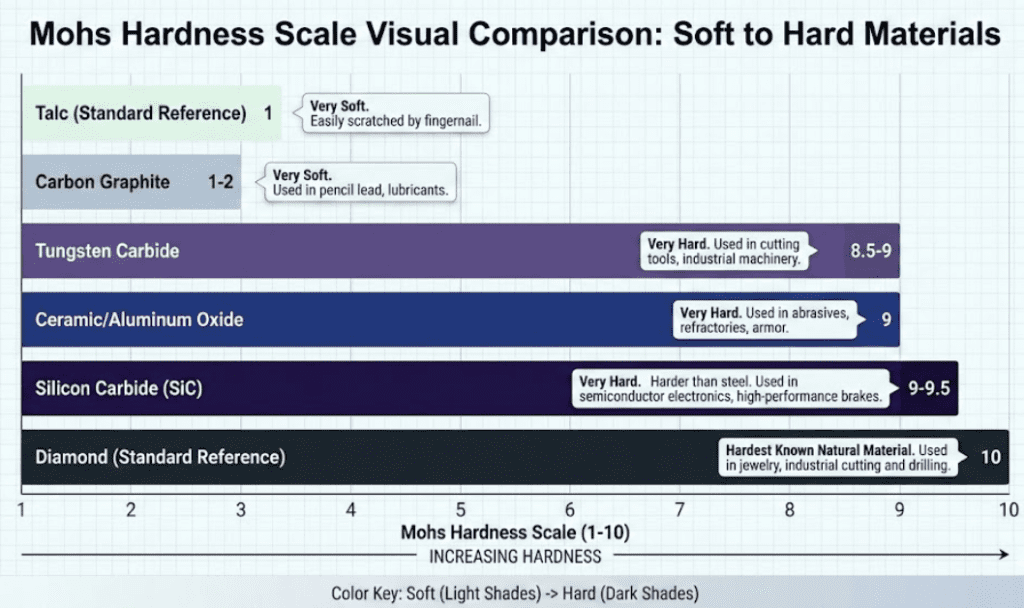

Different materials create different friction coefficients, which directly impacts heat generation and wear. Silicon carbide might be harder than diamonds, but pair it with the wrong soft face and you’ll get excessive wear. Carbon graphite works beautifully in water pumps but fails miserably in abrasive environments.

The Two Primary Material Combination Approaches

The mechanical seal industry has evolved around two fundamental strategies: soft-versus-hard combinations and hard-versus-hard combinations. Each approach solves different problems.

Soft vs. Hard Combinations: The Industry Standard

Most mechanical seals use a soft material paired with a hard material. Carbon graphite (the soft face) runs against silicon carbide or tungsten carbide (the hard face). This combination dominates the market for good reason—it works.

Here’s why this approach makes sense: soft materials like carbon graphite are self-lubricating. They reduce friction naturally. When you pair that self-lubricating soft face with an extremely hard surface, you get excellent wear performance without generating excessive heat. The carbon essentially protects itself by creating a sacrificial wear surface.

This combination works best in low-to-moderate viscosity fluids where the sealing fluid operates in boundary or mixed lubrication conditions. The fluid can’t completely separate the two faces, so you need materials that play nice together when touching.

Hard vs. Hard Combinations: When You Need Extreme Performance

Sometimes soft materials just don’t cut it. When you’re sealing abrasive slurries, high-debris fluids, or pushing extreme operating conditions, you pair two hard materials together. Silicon carbide versus silicon carbide, or tungsten carbide versus tungsten carbide.

These combinations sacrifice some of the self-lubrication benefits of soft materials but gain incredible wear resistance. You can run these combinations in extremely contaminated fluids where particles would shred carbon graphite in hours. The downside? Higher friction means more heat generation, and you need precision manufacturing to make hard-versus-hard combinations work reliably.

Choose hard-versus-hard when your application absolutely demands it—never as a default. The added cost and complexity only make sense when softer alternatives would fail.

How to Select the Right Seal Face Material Combination

Stop guessing. Follow this systematic approach and you’ll make the right choice every time.

Step 1: Assess Your Application Fluid

Start with the fluid you’re sealing. What is it? Water? Oil? Slurry? Chemical? Each type demands different materials.

Document the exact chemical composition if you can get it. Industrial solvents, process chemicals, and aggressive fluids require materials with proven chemical compatibility. You can’t just guess. Look up the fluid’s compatibility with your candidate materials.

Determine viscosity at your actual operating temperature. Low-viscosity fluids (thin, watery) demand soft-versus-hard combinations because the fluid can’t create a thick lubricating film. High-viscosity fluids (thick, heavy) generate better films, so both soft-versus-hard and hard-versus-hard work.

This single step eliminates half your options immediately.

Step 2: Evaluate Operating Conditions

Temperature matters more than you think. How hot does it actually get? Not the peak—the sustained operating temperature.

Record your pressure requirements, rotational speed in RPM, and any vibration or shock loading. Harsh operating conditions demand tougher materials like tungsten carbide.

Identify whether your fluid contains abrasive particles, suspended solids, or corrosive elements. Clean water pumps need different solutions than slurry applications or chemical process equipment.

Step 3: Match Materials to Conditions

Now combine your fluid analysis with operating conditions to identify viable material combinations.

Low-viscosity fluids without abrasives? Soft-versus-hard combinations with carbon graphite and silicon carbide. That’s the standard choice and it works.

Abrasive slurries with suspended solids? Hard-versus-hard combinations. Two silicon carbide faces or tungsten carbide against silicon carbide. Carbon simply wears too fast.

High-temperature applications exceeding 350°F? Silicon carbide or tungsten carbide as the hard face. Ceramic can’t handle the thermal stress. You need materials that maintain strength and resist thermal shock.

Corrosive chemical environments? Silicon carbide with its exceptional chemical resistance. It resists acids, bases, and aggressive chemicals that would attack other materials.

This matching process narrows your selection to maybe two or three viable combinations.

Step 4: Consider Cost vs. Performance

Premium seal materials cost more upfront, but they deliver lower lifecycle costs. This is where data matters.

Calculate your actual cost. Multiply seal cost by annual replacement rate, add maintenance labor costs, add lost production from downtime, then compare total costs across material combinations. What looks expensive upfront often becomes the best value when you account for everything.

Performance Comparison

Here’s the reality of how these materials actually compare:

Carbon graphite scores best in cost and self-lubrication but ranks poorly in hardness and thermal properties. It works great for moderate-duty applications but fails in demanding conditions.

Silicon carbide leads in tribological performance, thermal stability, and chemical resistance. It costs more but delivers exceptional results in most industrial applications. It’s the safe choice for critical equipment.

Tungsten carbide excels in impact resistance, thermal conductivity, and pressure capabilities. It costs more than silicon carbide but offers superior durability in the most extreme applications.

Ceramic ranks highest only in cost and hardness but fails dramatically in thermal shock and brittleness. Reserve it for low-duty applications only.

The real breakthrough combination remains carbon graphite versus silicon carbide. Industry experts consistently identify this pairing as having “the best wear characteristics of all possible face combinations.” It’s the combination that manufacturers recommend across countless industries.

Conclusion

Here’s what you now know: carbon graphite and silicon carbide remain the proven standard for most industrial applications. Tungsten carbide delivers when impact resistance and extreme pressure demand toughness. Ceramic only makes sense in low-duty stable environments.

Follow the four-step selection process. Assess your fluid. Evaluate conditions. Match materials logically. Calculate total cost, not just purchase price.

Stop losing money to preventable seal failures. Make informed decisions about seal face materials, and you’ll cut maintenance costs, extend equipment life, and eliminate the downtime that costs you money every single day.