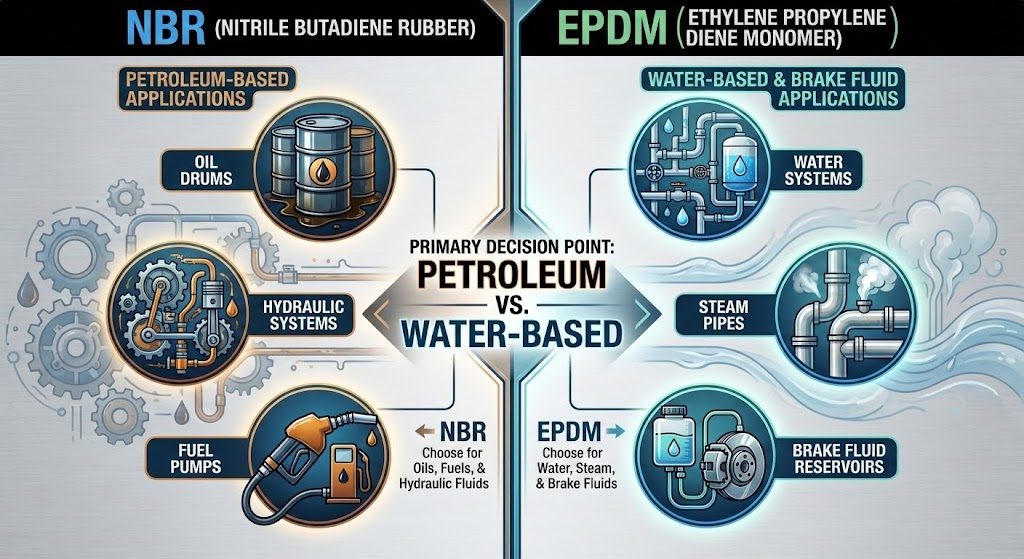

NBR is the most widely used elastomer in the seal industry today. But choosing it for a water or steam application guarantees premature failure. The reverse applies equally: install EPDM in a hydraulic system, and you will find swollen O-rings extruding from their grooves within weeks.

The selection between NBR and EPDM comes down to one factor: media type. Petroleum-based fluids require NBR. Water-based fluids require EPDM. Temperature range matters, but only after you have matched the material to your process fluid.

This guide provides the decision framework, specifications, and field diagnostics you need to select the correct elastomer for pump seals, O-rings, and gaskets.

Which Elastomer Should You Choose: NBR or EPDM?

Choose NBR for petroleum-based media. Choose EPDM for water-based or glycol-based media. This rule eliminates most selection errors.

The One Rule That Matters

Media compatibility determines elastomer selection. Temperature is secondary. Using EPDM “just to be safe” in an oil application causes the seal to swell, soften, and fail faster than a correctly specified NBR seal would.

For petroleum oils, lubricants, and fuels: specify NBR.

For water, steam, coolants, and brake fluids: specify EPDM.

If your application involves petroleum AND requires temperatures above 120C, neither material works. You need HNBR or FKM.

Quick Decision Matrix

| Application | Material | Reason |

|---|---|---|

| Petroleum oils/lubricants | NBR | Excellent hydrocarbon resistance |

| Mineral hydraulic fluids | NBR | Industry standard, proven performance |

| Gasoline/diesel fuel | NBR | Designed for fuel contact |

| Hot water/steam | EPDM | Resistant up to 150C |

| Engine coolant (glycol) | EPDM | Excellent glycol compatibility |

| Brake fluid (DOT 3/4/5.1) | EPDM | Only recommended elastomer |

| Outdoor/UV exposure | EPDM | Superior ozone/weather resistance |

| Alcohols (ethanol, methanol) | EPDM | NBR not compatible with alcohols |

| Food contact | Either | Both available FDA-compliant |

| Potable water | EPDM preferred | NSF 61 certified grades available |

Of all three common rubber types (NBR, FKM, and EPDM), EPDM is the only one that should be considered for use anywhere in a braking system. This is not a preference. It is a requirement based on glycol compatibility.

NBR Properties and Specifications

NBR (nitrile butadiene rubber) provides excellent resistance to petroleum products across a temperature range of -35C to +120C. This combination makes it the default choice for hydraulic systems, fuel handling, and lubricated rotating equipment.

Temperature and ACN Content Trade-offs

NBR is a copolymer of acrylonitrile (ACN) and butadiene. The ACN content directly controls the balance between oil resistance and low-temperature flexibility.

- 50% ACN: Optimum oil resistance, but low-temperature flexibility drops to -3C

- 33% ACN: Standard formulation balancing oil resistance and flexibility to -35C

- 18% ACN: Excellent cold flexibility to -48C, but only moderate oil resistance

For most applications requiring both solvent resistance and low-temperature flexibility, specify 33% ACN content. This is the industry default for good reason.

I recommend low-ACN formulations (18-25%) only when operating temperatures regularly drop below -40C. The trade-off in oil resistance is significant, so verify your lubricant compatibility before switching.

Chemical Resistance Profile

Excellent resistance:

- Petroleum oils and mineral oils

- Hydraulic fluids (petroleum-based)

- Aliphatic hydrocarbons

- Greases and fats

Poor resistance (avoid):

- Ozone and UV exposure

- Ketones (acetone)

- Alcohols (ethanol, methanol)

- Strong acids

NBR degrades rapidly when exposed to ozone. If your application involves outdoor exposure or proximity to electric motors (which generate ozone), switch to EPDM regardless of fluid type.

When to Specify NBR

Specify NBR for:

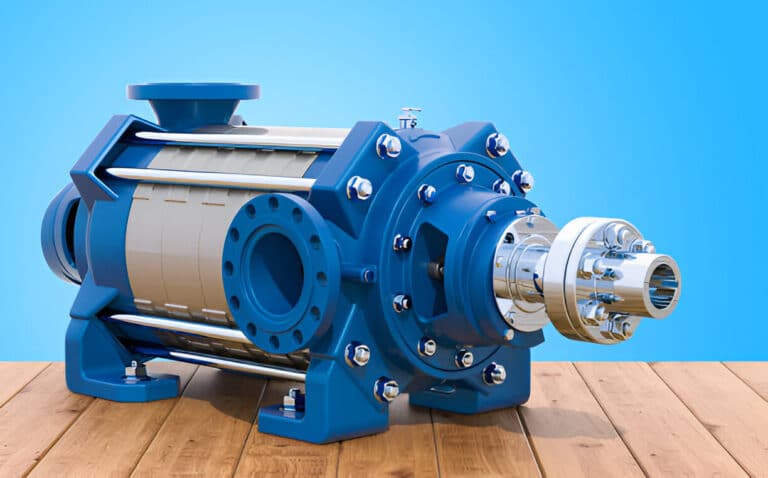

- Hydraulic systems with mineral oil

- Fuel handling equipment

- Lubricated rotating equipment

- Indoor pump applications without ozone exposure

NBR seals in hydraulic systems typically provide reliable long-term service when correctly specified. The material cost is lower than EPDM, and availability is excellent for standard durometer ranges.

EPDM Properties and Specifications

EPDM (ethylene propylene diene monomer) handles water, steam, and glycol-based fluids that would destroy NBR. The generic temperature range extends from -50C to +150C, making it the go-to material for hot water systems and automotive cooling circuits.

Temperature and Curing Effects

EPDM temperature limits depend on the curing method:

- Peroxide-cured EPDM: -50C to +150C (higher heat resistance)

- Sulfur-cured EPDM: -45C to +120C

EPDM O-rings are highly resistant to hot water, steam, and environments with excess moisture, capable of withstanding temperatures up to 150C (302F). For steam service, always specify peroxide-cured compounds.

The material exhibits elongation at break of 300% to 600%, providing excellent flexibility and resilience during thermal cycling. Tear resistance ranges from 10 to 40 kN/m, adequate for most mechanical seal applications.

Chemical Resistance Profile

Excellent resistance:

- Water (hot and cold)

- Steam (up to 150C)

- Glycol-based coolants and brake fluids

- Alcohols (ethanol, methanol, isopropyl)

- Ozone and UV exposure

- Dilute acids and bases

Poor resistance (avoid):

- Petroleum oils

- Mineral oils

- Hydrocarbon fuels

- Aromatic solvents

EPDM swells and degrades in petroleum contact. I have seen cases where EPDM O-rings increased significantly in volume within hours of oil exposure. The swollen seal extruded from its groove and caused immediate leakage.

When to Specify EPDM

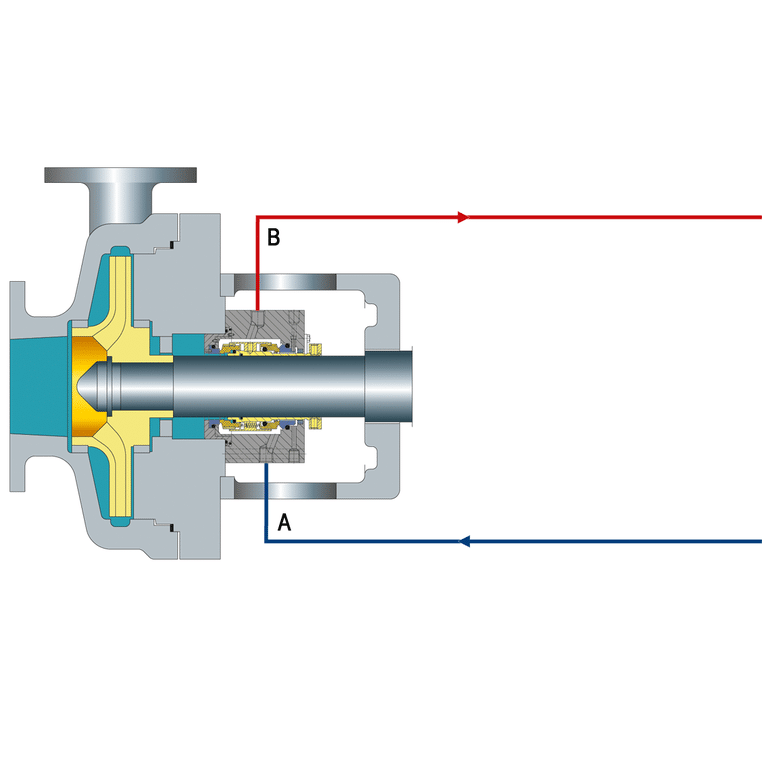

Specify EPDM for:

- Hot water and steam systems

- Automotive cooling systems

- Brake systems (glycol-based fluids only)

- Outdoor applications with UV/ozone exposure

- Alcohol-based cleaning systems

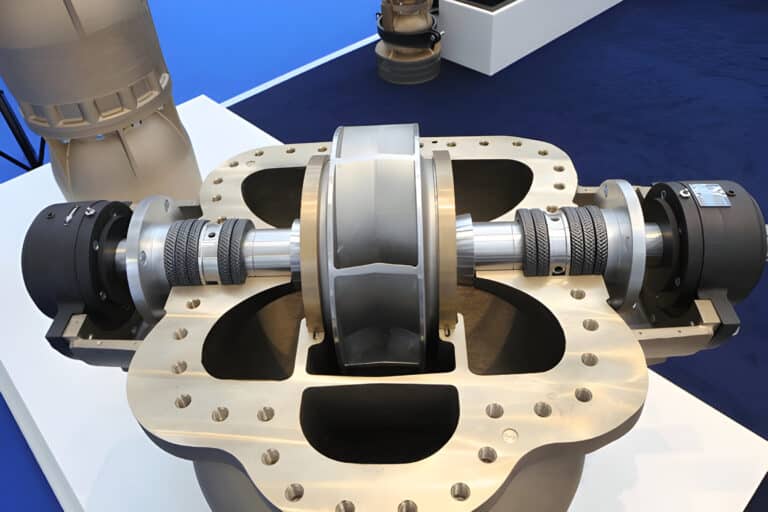

- Pump cooling seal systems

EPDM is cost-effective compared to silicone or fluorocarbon (FKM) and provides a broader temperature range than nitrile. For water service, it remains the default recommendation.

Temperature-Based Selection Guide

Temperature alone does not determine elastomer selection. However, once you have matched the material to your media type, temperature range narrows your compound options.

| Temperature Range | Petroleum Media | Water/Glycol Media |

|---|---|---|

| Below -40C | Low-ACN NBR (18-25%) | EPDM |

| -40C to +100C | Standard NBR (33% ACN) | EPDM |

| +100C to +120C | NBR (peroxide-cured) | EPDM |

| +120C to +150C | HNBR | EPDM (peroxide-cured) |

| Above +150C | HNBR or FKM | FKM |

For applications spanning multiple temperature zones, select the compound that handles your peak operating temperature. Occasional excursions above the rated maximum accelerate aging but do not cause immediate failure if kept brief.

I recommend maintaining at least 10C margin below the material’s maximum continuous service temperature. This margin accounts for localized hot spots at seal faces and provides a safety factor for process upsets.

When Neither NBR Nor EPDM Works: HNBR Alternative

HNBR (hydrogenated nitrile butadiene rubber) fills the gap when you need oil resistance above 120C. EPDM cannot handle hydrocarbons at any temperature, so upgrading to EPDM for high-temperature oil service causes immediate failure.

Why HNBR Exists

NBR loses mechanical properties above 120C. The butadiene component degrades, causing hardening and eventual cracking. But switching to EPDM introduces chemical incompatibility with the oil itself.

HNBR solves this problem through hydrogenation, which stabilizes the polymer backbone. The result is a material applicable to the temperature range of -40C to +170C while maintaining oil and fuel resistance comparable to NBR.

When to Specify HNBR

Specify HNBR for:

- High-temperature petroleum applications (above 120C)

- Applications requiring better ozone resistance than NBR

- Extended service life requirements justifying higher material cost

- Automotive timing belt covers and oil seals

HNBR costs significantly more than standard NBR. For high temperature mechanical seal applications running above 120C with petroleum-based barrier fluids, the additional cost extends seal life significantly.

Next Steps

You now have the framework to select between NBR and EPDM based on your application’s media type, temperature range, and operating conditions. For petroleum service below 120C, NBR remains the industry standard. For water, steam, and glycol service, EPDM handles conditions that would rapidly degrade nitrile compounds.

If your application involves mixed media, high temperatures, or aggressive chemicals beyond these two materials, explore HNBR, FKM, or PTFE alternatives. Contact Cowseal for material selection guidance specific to your operating conditions.