A diaphragm pump, also known as a membrane pump or a pneumatic pump, is a positive displacement pump that uses a flexible membrane, or diaphragm, to move fluids. These pumps are designed to handle a wide variety of liquids, including viscous, abrasive, and corrosive substances, making them suitable for numerous industrial applications. The pump’s mechanism isolates the fluid from the pump’s internal components, which is a distinct advantage when dealing with sensitive or hazardous materials.

What Is a Diaphragm Pump

A diaphragm pump is a type of positive displacement pump that utilizes the reciprocating action of a flexible diaphragm to move liquids. This diaphragm, typically made of rubber, thermoplastic, or Teflon, forms a seal that separates the liquid being pumped from the pump’s mechanical components. By varying the chamber volume, fluid is drawn into the pump and then expelled. This design is especially useful for applications where fluid purity, or the prevention of leaks, is essential.

Types of Diaphragm Pumps

Diaphragm pumps are available in several configurations, each suited to different applications. The most common types include:

Single Diaphragm Pumps

Single diaphragm pumps use a single diaphragm to displace the fluid. The pump’s operation involves the diaphragm moving back and forth, creating a vacuum to draw fluid into the pump chamber on one stroke, and then pushing fluid out on the opposite stroke. These pumps are often used for lower flow applications.

Double Diaphragm Pumps

Double diaphragm pumps utilize two diaphragms linked by a shaft. The diaphragms move in tandem, creating a more continuous and balanced flow. One diaphragm draws fluid into its chamber while the other expels fluid, resulting in a smoother discharge. This design is particularly useful for handling more viscous fluids and maintaining a steady output.

AODD Pumps

Air-operated double-diaphragm (AODD) pumps use compressed air to actuate the diaphragms. This makes them suitable for use in hazardous or explosive environments, as they do not require electrical power. AODD pumps are also highly versatile, capable of handling a wide range of fluid types.

Mechanically Driven Diaphragm Pumps

In mechanically driven diaphragm pumps, the diaphragm is moved by a mechanical linkage connected to a motor. The movement is controlled by cams, cranks, or other mechanical systems. This type of pump typically provides a precise and controlled flow rate.

Electrically Driven Diaphragm Pumps

Electrically driven diaphragm pumps use an electric motor to move the diaphragm. These pumps are often used in situations requiring precise flow rates and can be integrated into automated systems. They are generally more energy-efficient than air-operated models.

Components of Diaphragm Pumps

Diaphragm pumps consist of several key components that work together:

The Diaphragm

The diaphragm is the core component, creating a seal that isolates the pumped fluid from the pump’s internal mechanism. It is typically made from flexible material and moves back and forth.

Pump Chamber

The pump chamber is the space where the fluid is drawn in and expelled. Its volume changes with the movement of the diaphragm, enabling the pump to displace fluid.

Valves

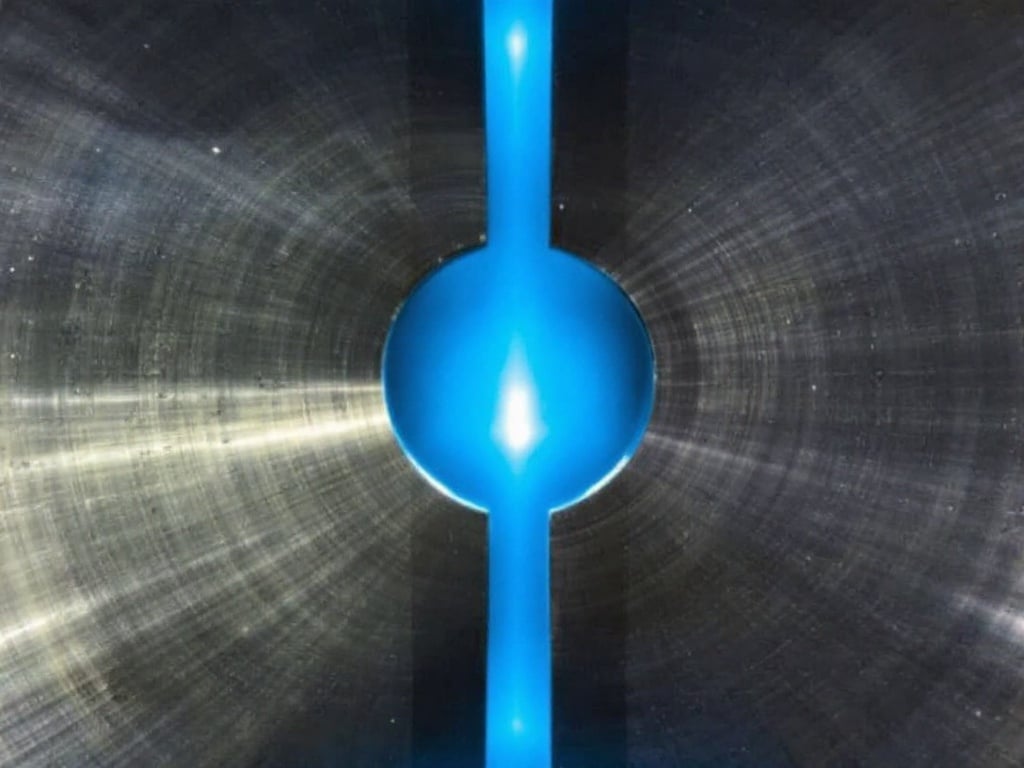

Inlet and outlet valves regulate fluid flow into and out of the pump chamber. These valves, which can be ball, check, or other designs, ensure the fluid moves in the desired direction.

Actuation Mechanism

The actuation mechanism is responsible for moving the diaphragm. This could be a mechanical linkage, compressed air, or an electrical motor, depending on the pump type.

Suction and Discharge Manifolds

Suction and discharge manifolds are the connections where fluid enters and exits the pump. They are designed to provide efficient flow and minimize pressure losses.

How Diaphragm Pumps Work

Diaphragm pumps utilize a reciprocating action of a flexible diaphragm to move fluids. This process involves several key steps that create a pumping motion.

The core of the operation is the diaphragm, a flexible membrane. This diaphragm is connected to a drive mechanism, which can be mechanical, pneumatic, or electrical. When the drive mechanism is activated, it moves the diaphragm back and forth within the pump chamber. This movement changes the volume of the pump chamber, creating the pumping action.

- Suction Phase: During the suction phase, the diaphragm is pulled back. This increases the volume of the pump chamber, creating a vacuum that draws fluid into the pump through the inlet valve. The outlet valve is closed during this phase to prevent backflow.

- Discharge Phase: Once the chamber is filled, the drive mechanism pushes the diaphragm forward. This reduces the volume of the chamber, increasing pressure and forcing the fluid through the outlet valve and out of the pump. Simultaneously, the inlet valve closes, preventing fluid from flowing back into the suction line.

The reciprocating motion of the diaphragm, alternating between suction and discharge phases, results in a continuous flow of fluid. This process is repeated to provide consistent pumping. The pump’s check valves, located at both the inlet and outlet, manage the flow of fluid, ensuring it travels in only one direction. They prevent the fluid from flowing back toward the inlet during the discharge phase and prevent backflow into the pump from the discharge line during suction.

Advantages of Diaphragm Pumps

Handling Viscous Fluids

Diaphragm pumps are proficient at pumping fluids with high viscosity. The large clearances and simple design allow for easy passage of thick substances without clogging.

Abrasive Fluid Handling

The pumps can handle fluids containing abrasive particles. The flexible diaphragm minimizes contact with moving parts, reducing wear and tear on the pump.

Self-Priming Capabilities

Diaphragm pumps have the ability to self-prime. They can effectively draw fluids from below the pump without requiring initial filling of the suction lines.

Dry Running Capabilities

The pumps are resistant to damage when running without fluid, known as dry running, for short periods. This is because the diaphragm protects internal parts from friction and heat buildup.

Chemical Resistance

Diaphragm pumps are compatible with a wide variety of chemicals. The diaphragm and wetted parts can be made from materials that resist corrosion and degradation.

Leak Free Operation

Due to the seal the diaphragm creates, the pumps are leak-free. This is important for pumping hazardous or valuable liquids.

Disadvantages of Diaphragm Pumps

Pulsating Flow

Diaphragm pumps can generate a pulsating flow, particularly single diaphragm types. This can be problematic for applications that require a steady, consistent flow.

Lower Pressure and Flow

Generally, diaphragm pumps have limitations on flow rates and pressure capabilities compared to centrifugal or piston pumps.

Maintenance Requirements

Although the design is robust, diaphragms will eventually require replacement due to wear and fatigue, and this adds to the maintenance time and costs.

Noise

Air-operated pumps can be noisy during operation. Although other configurations are less noisy, noise can still be an issue for certain applications.

Size

Diaphragm pumps can be larger and more cumbersome compared to some other types of pumps with similar flow rates, which may make them difficult to use in small spaces.

Applications of Diaphragm Pumps

Chemical Industry

Diaphragm pumps are often used in chemical processing plants to handle corrosive and hazardous materials. They are designed to ensure a safe and reliable transfer.

Wastewater Treatment

These pumps are used for metering chemicals in wastewater treatment and moving sludge, owing to their ability to handle solids.

Food and Beverage Industry

Diaphragm pumps are utilized to transfer food products and beverages, as they are capable of sanitary operation.

Pharmaceutical Industry

The pumps are used in the pharmaceutical industry because they can handle sterile and sensitive fluids without contaminating them.

Mining Operations

Due to their ability to handle abrasive materials, diaphragm pumps are used for pumping slurries and other viscous materials in mining operations.

Paint and Coating Applications

These pumps are commonly used for transferring paints, coatings, and adhesives because they can handle the consistency of such materials.

Oil and Gas

Diaphragm pumps are used for pumping and transferring various fluids in oil and gas production, including drilling mud and chemical additives.

How to Select the Right Diaphragm Pump

Selecting the correct diaphragm pump involves careful consideration of several factors:

- Matching the Pump to the Specific Application and Requirements: First and foremost, the pump’s capability must match the requirements of the specific application, regarding fluid properties, location of use, and the task it needs to perform.

- Flow Rate: Evaluate the required flow rate to ensure the pump’s capacity meets the operational demands. Over or under sizing the pump may lead to inefficiencies or performance issues.

- Pressure: Select a pump that is capable of meeting the system’s pressure requirements, taking into consideration the pressure of the fluid itself.

- Fluid Type: Assess the fluid’s viscosity, abrasiveness, chemical nature, and temperature to ensure compatibility with the pump materials.

- Size Selection: Ensure that the physical size of the pump fits within the installation space and any space constraints of the environment.

- Cost: Evaluate the cost-effectiveness of the pump, taking into consideration its operational cost, lifespan, and the cost of parts replacement to find the most cost effective choice for the particular use.

Common Problem with Diaphragm Pumps

- Diaphragm Failure: Diaphragms can fail due to fatigue or chemical degradation, requiring replacement.

- Valve Issues: Valves may wear or become clogged, which affects flow rates and pressures.

- Leaks: Leaks can occur around seals and connections, requiring careful inspection and repairs.

- Air Leaks (AODD pumps): Air leaks in AODD pumps can reduce efficiency and cause operational issues.

- Pulsation: Pulsation in the flow may cause system vibrations, and require additional equipment, like pulsation dampeners.

Diaphragm Pumps Vs. Other Pump Types

| Feature | Diaphragm Pump | Centrifugal Pump | Gear Pump |

|---|---|---|---|

| Fluid Handling | Excellent for viscous, abrasive, and corrosive fluids | Best for thin, clean fluids | Suitable for viscous fluids and oils |

| Flow Rate | Typically lower flow rates | Higher flow rates | Moderate flow rates |

| Pressure | Moderate pressure capabilities | Low to high pressure capabilities | Moderate to high pressure capabilities |

| Self-Priming | Excellent self-priming ability | Generally require priming | Self-priming capabilities with specific types |

| Dry Running | Can handle dry running for short periods | Not suited for dry running | Dry running will cause damage. |

| Maintenance | Requires diaphragm and valve maintenance | Typically less maintenance | May require regular gear and seal maintenance. |

| Cost | Moderate to high cost, depending on materials | Generally lower initial cost | Moderate cost |

| Applications | Chemical, wastewater, food, mining, pharmaceutical | Water transfer, HVAC, general purpose fluid handling | Lubrication, hydraulic systems, industrial fluids |