Pump packing materials are critical for ensuring reliable and efficient pump operation. However, with so many options available, selecting the right packing material for your specific application can be a challenge.

Using the wrong packing material can lead to premature failure, increased maintenance costs, and unexpected downtime. Factors like shaft speed, fluid temperature, and pH levels must be carefully considered to avoid costly mistakes.

In this blog post, we’ll explore the different types of pump packing materials available, including flax, acrylic, novoloid, aramid, PTFE, expanded PTFE, carbon/graphite, and flexible graphite tape. We’ll also provide guidance on how to select the right material based on your specific operating conditions, helping you optimize performance and minimize maintenance requirements.

Types of Pump Packing Materials

Flax

Flax packing is made from the long, strong fibers of the flax plant. It has good lubricity and thermal conductivity, making it suitable for applications with low to medium shaft speeds, up to 2000 fpm. Flax packing performs well in temperatures up to 250°F (121°C) and can handle most non-caustic fluids with a pH range of 5-9.

Acrylic

Acrylic packing is made from synthetic acrylic fibers. It offers improved thermal resistance and chemical compatibility compared to flax packing. Acrylic packing can operate at shaft speeds up to 2500 fpm and withstands temperatures up to 350°F (177°C). It is resistant to oils, solvents, and mildly acidic or alkaline fluids with a pH range of 4-11.

Novoloid

Novoloid packing is made from phenol-formaldehyde fibers. It provides excellent strength, dimensional stability, and resistance to wear and abrasion. Novoloid packing handles shaft speeds up to 3000 fpm and temperatures up to 500°F (260°C). It withstands exposure to most acids, alkalis, solvents, and steam, covering a pH range of 0-14.

Aramid

Aramid packing utilizes high-strength, heat-resistant synthetic fibers such as Kevlar or Nomex. It offers outstanding toughness, tensile strength, and thermal stability. Aramid packing accommodates shaft speeds up to 4000 fpm and temperatures up to 500°F (260°C). It resists abrasion and chemical attack from acids, alkalis, and solvents within a pH range of 2-12.

PTFE

PTFE (polytetrafluoroethylene) packing is made from pure PTFE resin. It provides a low coefficient of friction, excellent chemical inertness, and a wide service temperature range. PTFE packing is suitable for shaft speeds up to 1800 fpm and temperatures from -400°F to 500°F (-240°C to 260°C). It is compatible with nearly all fluids and gases, covering the full pH range of 0-14.

Expanded PTFE

Expanded PTFE packing incorporates a microporous PTFE structure for enhanced pliability and conformability. It shares the low friction and non-stick properties of standard PTFE packing while offering improved sealability in dynamic applications. Expanded PTFE packing handles shaft speeds up to 2000 fpm and a temperature range of -400°F to 500°F (-240°C to 260°C). It maintains chemical inertness across the full pH spectrum.

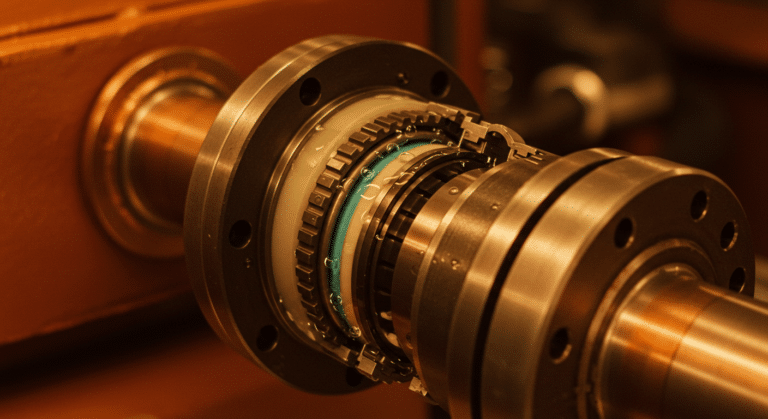

Carbon/Graphite

Carbon/graphite packing contains high-purity carbon or graphite filament yarns with added lubricants. It provides excellent heat dissipation, low friction, and resistance to chemical attack and galvanic corrosion. Carbon/graphite packing operates at shaft speeds up to 4000 fpm and temperatures up to 1200°F (650°C) in non-oxidizing environments. It withstands exposure to most acids, alkalis, and solvents, covering a pH range of 0-14.

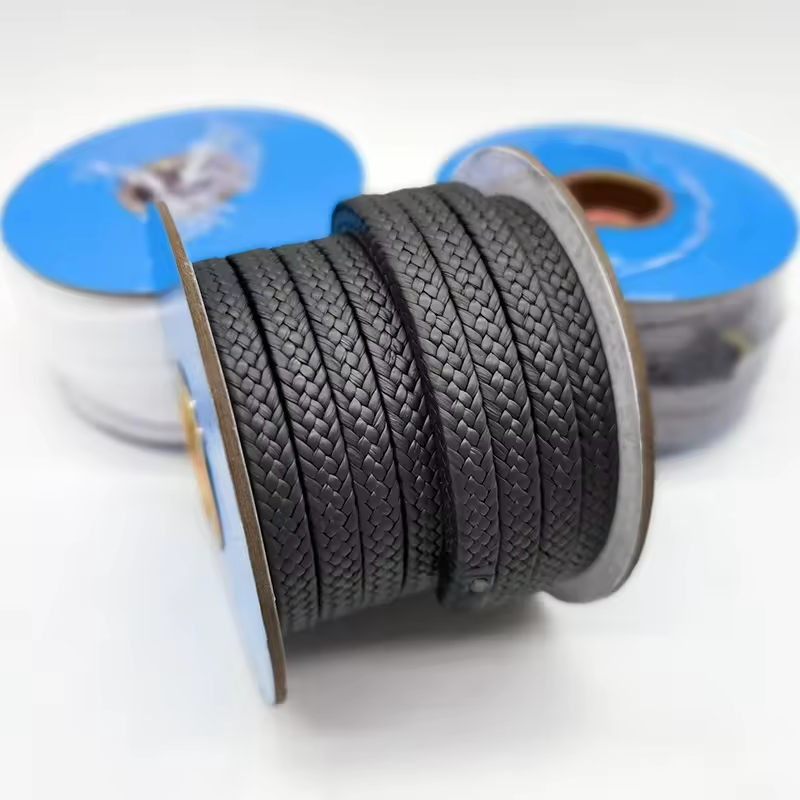

Flexible Graphite Tape

Flexible graphite tape packing is made from pure, expandable graphite with an adhesive backing. It conforms well to stuffing box irregularities and mating surfaces. Flexible graphite tape handles shaft speeds up to 4500 fpm and temperatures up to 1200°F (650°C) in non-oxidizing atmospheres. It maintains chemical resistance across the full pH range and exhibits low friction and high thermal conductivity.

Selecting Pump Packing Materials

Shaft speed

The shaft speed, measured in feet per minute (fpm), influences the selection of packing material. Higher shaft speeds generate more heat through friction and require packing materials with better heat dissipation properties. Carbon/graphite and flexible graphite packings handle the highest shaft speeds, up to 4500 fpm.

Fluid temperature

The temperature of the pumped fluid dictates the thermal stability requirements for the packing material. PTFE and expanded PTFE offer the widest temperature range, from cryogenic conditions to 500°F (260°C). For extreme high temperatures up to 1200°F (650°C), carbon/graphite or flexible graphite packings are suitable choices.

pH of the pumped fluid

The pH level indicates the acidity or alkalinity of the pumped fluid. Packing materials vary in their resistance to different pH ranges. PTFE-based packings provide the most comprehensive chemical compatibility, withstanding the full pH spectrum of 0-14. Novoloid, carbon/graphite, and flexible graphite also exhibit broad chemical resistance. For mildly acidic or alkaline fluids, acrylic packing is a cost-effective option.