Why do vertical multistage pump seals fail differently than horizontal pump seals? The seal sits at the top of the pump, creating an inverted cup that traps air even when liquid is present below. I have seen technicians replace seals using standard horizontal pump procedures, only to watch the new seal fail within days. Vertical multistage pumps demand a different approach.

This guide walks through the complete replacement procedure with the specific tolerances and checkpoints that vertical configurations require.

Pre-Disassembly Checks

Before you start, measure shaft runout at the seal location using a dial indicator. Standard tolerance is 0.001 to 0.002 inches TIR (Total Indicated Runout). For vertical cooling tower pumps and similar applications, allow no more than 0.003 inch TIR just above the seal location. If runout exceeds these values, the seal will fail regardless of installation quality.

Check shaft surface finish where the dynamic O-ring rides. Dynamic sealing surfaces require 32 RMS maximum, preferably 16 RMS for significant axial movement. Static O-ring surfaces need 45 RMS maximum. Scratches or nicks running longitudinally under the seal will seep and start a leak.

Decide whether to remove the motor. For motors under 5 HP with good overhead access, removal simplifies the work. Larger motors can stay in place if you can safely support the shaft during disassembly. The most common mistake I see is attempting to work around an unmoved motor that blocks access, leading to rushed steps and installation errors.

Gather your replacement seal, O-rings, and gaskets before starting. Verify the new seal matches the original in size and configuration. Have clean rags, appropriate lubricant (silicone grease or manufacturer-recommended), and a torque wrench ready.

Disassembly Sequence

Mark each stage with a paint pen or scribe before removal. Multistage pumps must reassemble in exact original order. Mix up the stages and you will have imbalance, vibration, and rapid seal failure.

Remove the coupling carefully. Never hammer couplings onto or off the shaft. Mechanical seal faces are extremely flat, lapped to less than 3 helium light bands (about 1 micron). Hammering transmits shock through the shaft and can crack or distort these precision surfaces.

Support the long shaft vertically during disassembly. Horizontal storage invites bending. Use a clean, padded vertical stand or hang the shaft assembly from the coupling end. Even slight shaft bow amplifies runout at the seal location.

Remove stages sequentially from the top. Keep hardware organized by stage. Document any shims or spacers, their thickness, and location. These control internal clearances and stage alignment.

Old Seal Removal and Inspection

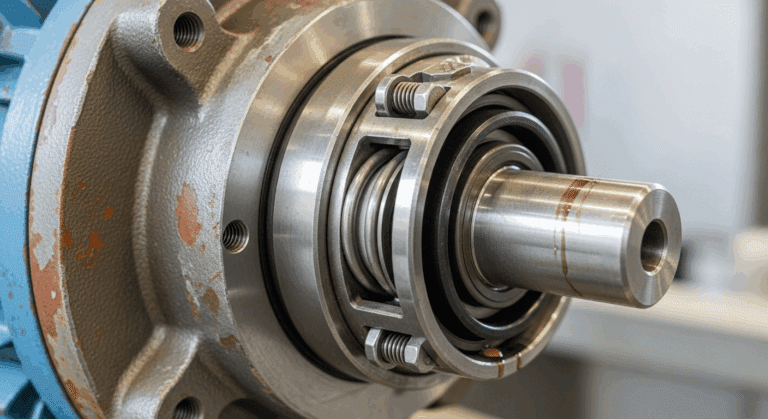

Extract the old seal without scoring the seal chamber bore. Pry points should contact the seal gland or sleeve, not the chamber surface. Any damage to the chamber bore creates a leak path that no seal can overcome.

Inspect the seal chamber bore for concentricity: API 610 specifies 0.005 inches TIR maximum. Seal chamber face runout should not exceed 0.0005 inches per inch of bore diameter. Out-of-tolerance chambers require machining or sleeve installation before proceeding.

Examine the old seal faces. Seal faces in good condition show uniform wear patterns. Heat checking (radial cracks), scoring, or uneven wear indicates operational problems that seal replacement alone will not solve. A case study of an ammonia pump at a cold storage facility found piping sloped in the wrong direction and significant misalignment. Replacing the seal alone would have been a temporary fix.

Check shaft sleeve surface condition. The seal surface really needs to be mirror finish. Any visible scratches, grooves, or pitting means the sleeve requires replacement or refinishing. Worn sleeves leak.

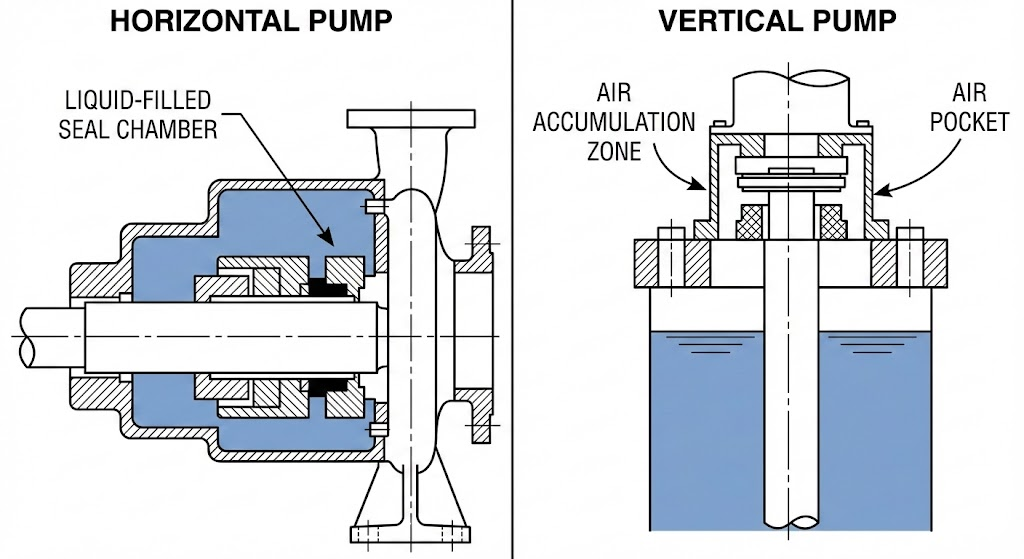

Understanding Vertical Air Trapping

This is where vertical pumps differ fundamentally from horizontal units. Picture pushing an empty cup with the open end down into a container filled with water. Air trapped in the cup has nowhere to go. If a sealed shaft passed through that cup, the air would remain trapped around it.

That is exactly what happens in a vertical pump. The seal chamber at the top acts as an inverted cup. Air collects above the liquid and surrounds the seal faces. In horizontal pumps, seals are almost always surrounded by liquid. In vertical pumps, this should never be taken for granted.

A wastewater treatment plant in Amherst, NY experienced repeated seal failures despite using quality seals. Investigation revealed flush water carrying entrained air that collected in seal chambers, creating dry pockets around the seal faces. The solution was installing float and needle valves above the seal for constant venting.

The consequences of running a seal dry are severe. Under the right conditions, mechanical seals can experience thermal shock and shatter within 30 seconds or less. Verify your pump has adequate venting before reassembly.

New Seal Installation

Handle the new seal by the gland or sleeve only. Even fingerprints on seal faces can cause initial leakage. Seal faces are lapped to within 2 to 3 helium light bands (0.58 to 0.87 microns). Any contamination on these surfaces prevents the fluid film from forming properly.

Check O-ring compression before installation. Static O-rings require 10% to 40% compression. Dynamic O-rings require 10% to 30% compression. Under-compressed O-rings leak. Over-compressed O-rings bind and cause uneven face loading.

Set spring compression according to manufacturer specifications. Typical compression distance ranges from 0.100 to 0.150 inches. Single-spring seals operate at 50-70% compression; multi-spring designs run closer to 90%. Incorrect compression either starves the faces of closing force or overloads them.

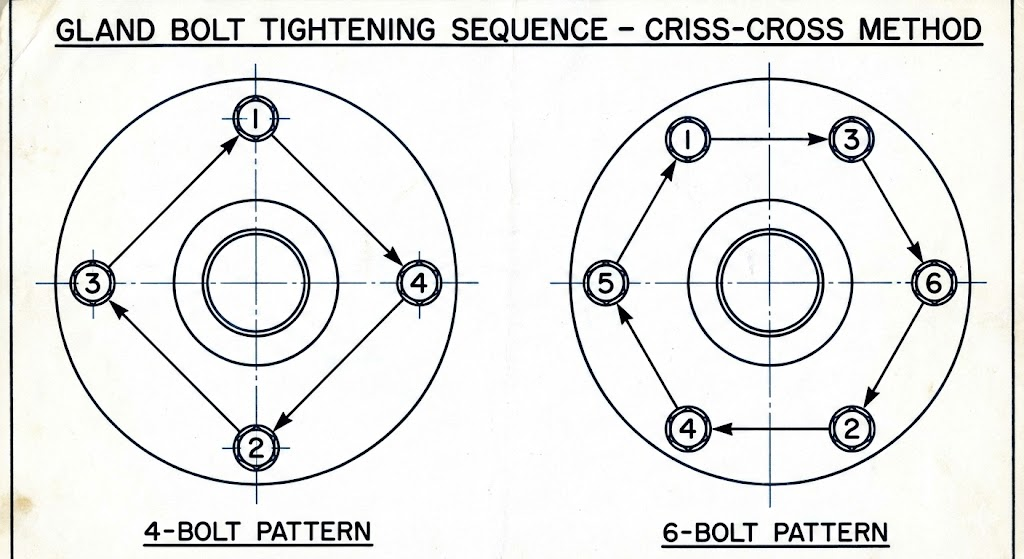

Torque gland bolts in a criss-cross pattern. For Grundfos CR seals, final torque is 35 Nm using the ring insert tool. Tighten progressively: 30%, then 60%, then 100% of final torque. Uneven tightening cocks the stationary ring and guarantees leakage.

Lubricate O-rings lightly with silicone grease or the manufacturer’s recommended lubricant. Avoid petroleum-based products on EPDM elastomers.

Reassembly and Verification

Reassemble stages in reverse order of disassembly. Verify each stage aligns with your original markings. Cross-check impeller orientation, stage sequence, and hardware torque.

Before final assembly, verify shaft-to-gland spacing. Typical spacing is 3-5mm. Check coaxiality between shaft and gland bore. Misalignment here transfers directly to the seal faces.

Install seal piping with proper slope. API 682 recommends half inch per foot (40 mm per meter) of slope for tubing runs. Improper slope traps air and defeats the venting system.

Prime and vent the pump completely before starting. Open all vent connections. Verify liquid reaches the seal chamber. For vertical pumps, this step prevents the air trapping that destroys seals.

Monitor initial operation closely. Seal chamber should maintain at least 5 psi gauge pressure during operation per API 610. Watch for leakage, unusual noise, or temperature rise at the seal area. For hot water applications above 80C, consider whether API Plan 23 closed-loop cooling is needed, as water lubricity decreases at elevated temperatures.

Next Steps

After startup, document the installation date, runout measurements, and any observations. If the seal fails within the first week, suspect installation error or system issues rather than seal defect. Check for incomplete venting, misalignment, or piping problems before ordering another seal.