What Is a Spring Loaded Device

A spring loaded device is a mechanical component that utilizes a spring to apply a constant force or maintain a specific position. These devices are designed to store potential energy in the spring and release it as kinetic energy when needed.

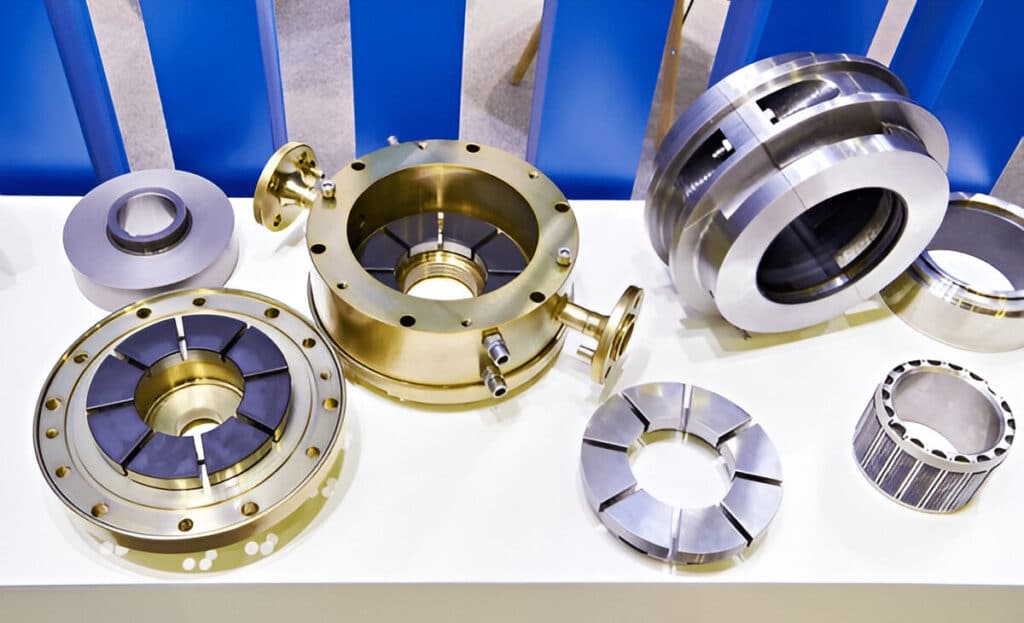

Components of Spring Loaded Device

- Spring: The core component of a spring-loaded device, providing a constant force in its resting position. Compression springs are commonly used, which are designed to resist compression and return to their original shape when the load is removed.

- Body: The enclosure that houses the spring and other components. The body can be threaded or push-fit, depending on the specific design and application requirements.

- Plunger or ball tip: The component that makes contact with the external surface or object. When an external force exceeds the spring force, the plunger or ball tip retracts into the body, compressing the spring. Once the external force is removed, the spring pushes the plunger or ball tip back to its original position.

Types of Spring Loaded Devices

Spring Plungers

Spring plungers are the most common type of spring-loaded device. They consist of a plunger with a rounded nose, a compression spring, and a threaded or press-fit body. The plunger provides a consistent force and can be used for various applications, such as holding, positioning, or locating components.

Stubby Spring Plungers

Stubby spring plungers are similar to standard spring plungers but have a shorter body length. They are ideal for applications with limited space or shallow installation depths.

Ball Plungers

Ball plungers feature a ball-shaped tip instead of a plunger. The ball tip allows for multi-directional contact and is often used in detent applications or as a ball nose for locating and aligning components.

Push-Fit/Press-Fit Plungers

Push-fit or press-fit plungers have a smooth body that is designed to be pressed into a hole or cavity. They provide a simple and economical solution for applications that don’t require the holding power of a threaded plunger.

Spring Stop Buttons

Spring stop buttons are small, low-profile devices that provide a controlled stopping force for lightweight objects. They are commonly used in consumer applications and equipment to prevent unwanted movement or vibration.

Spring Locating Pins

Spring locating pins are used for precise positioning and alignment of components. They feature a cylindrical pin with a rounded or tapered end, which is pushed into a locating hole to ensure accurate positioning.

Hand-Retractable Plungers

Hand-retractable plungers, also known as pull-pin spring plungers, allow for manual retraction of the plunger. They are often used in applications where temporary disengagement of the plunger is required, such as in locking mechanisms or quick-release systems.

Index Plungers and Bushings

Index plungers and bushings are used for precise indexing and positioning applications. They typically feature a spring-loaded plunger that engages with an indexing hole or slot, providing a positive stop and ensuring accurate alignment.

Design of Spring Loaded Device

When designing a spring loaded device, several key factors must be considered:

- End Force: The amount of force required to fully compress the spring and the force exerted by the plunger at various positions.

- Travel: The distance the plunger moves from its unloaded position to its fully compressed position.

- Thread Size: The size of the threaded body, which determines the holding power and the size of the mounting hole.

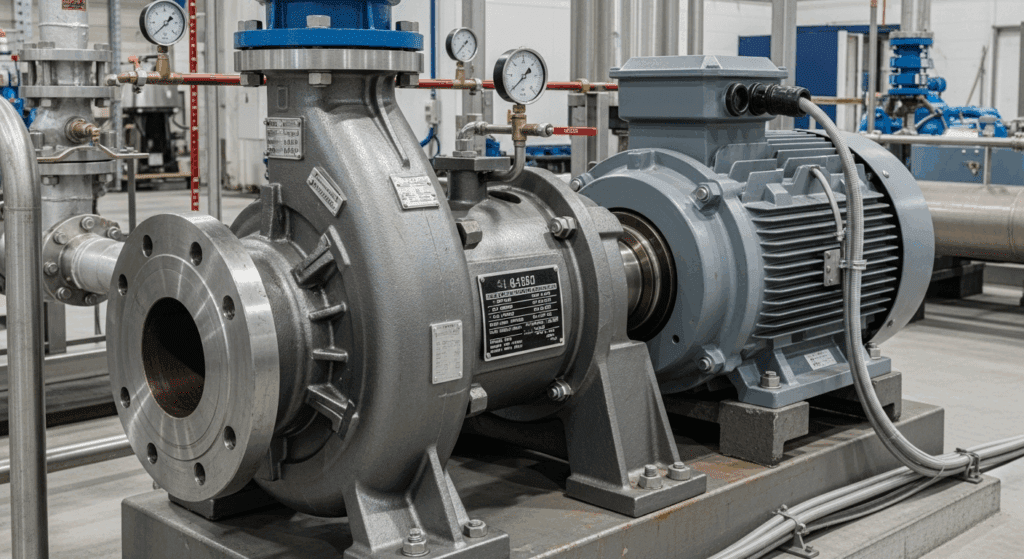

Applications of Spring Loaded Device

- Clamping and holding: Spring-loaded devices are commonly used for clamping and holding components in place during assembly or machining processes.

- Indexing and positioning: Spring-loaded pins and plungers are used for accurate indexing and positioning of components, ensuring precise alignment and repeatability.

- Vibration dampening: Spring-loaded devices can be used to absorb vibrations and shocks, preventing damage to sensitive components or equipment.

- Quick-release mechanisms: Hand-retractable plungers are used in quick-release mechanisms, allowing for easy and fast disengagement of components.

- Detent applications: Ball plungers are often used in detent applications, providing a tactile feedback and holding force for components such as knobs, levers, or switches.

Benefits of Spring Loaded Device

Spring loaded devices offer several advantages over simple springs:

- Precise and Repeatable End Forces: Enable reliable operation. The combination of a spring and a plunger provides consistent and predictable forces, ensuring reliable performance.

- Easy Installation and Setup: Spring loaded devices are self-contained units that are easy to install and set up, reducing assembly time and effort.

- Single Assembly Replacement: A spring loaded device can replace multiple components, simplifying the design and reducing the number of parts required.

- Minimal Spring Compression Set: High-quality spring loaded devices are designed to minimize spring compression set, ensuring consistent performance over the device’s life.

FAQs

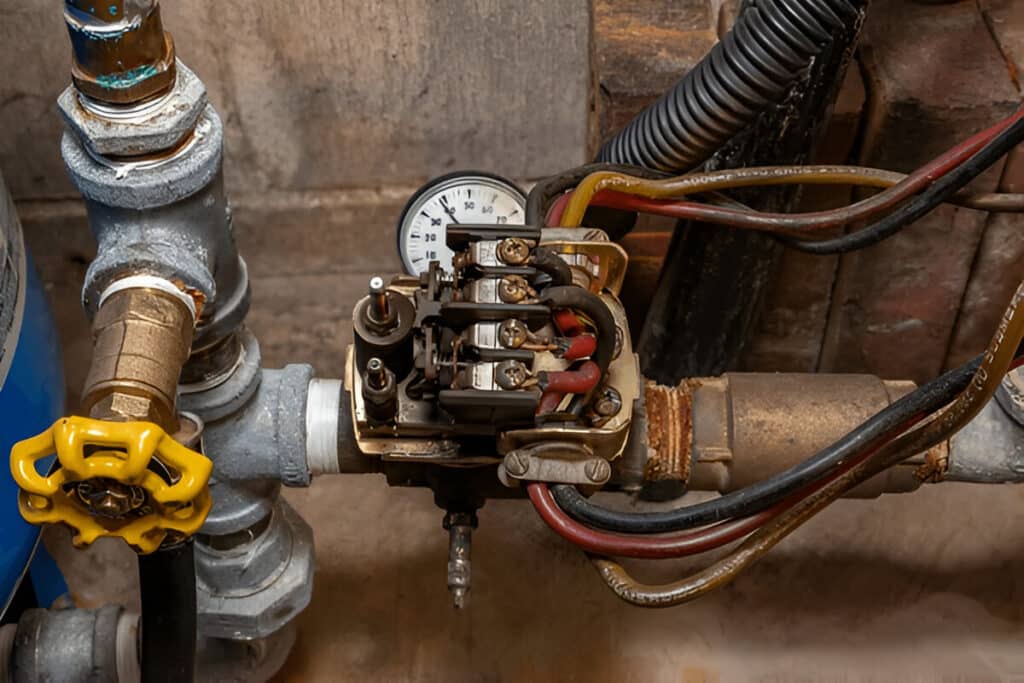

What Is the Use of a Spring Loaded Valve?

A spring loaded valve uses a spring to maintain a constant force on the valve seal, ensuring proper contact and preventing leaks. When the pressure exceeds the spring force, the valve opens to relieve pressure or allow flow.

What Is Spring Load?

Spring load refers to the force exerted by a spring in a spring loaded device. It is determined by the spring’s stiffness and the amount of compression or extension applied to the spring.