A wave spring mechanical seal is a specialized sealing solution designed to prevent leakage in rotating equipment. It consists of a series of nested wave springs that apply a constant force to the seal faces, maintaining a tight seal even under varying pressure and temperature conditions.

The unique wave spring design allows for a more compact and lightweight seal compared to traditional mechanical seals, making it ideal for applications with limited space.

What is a Wave Spring Mechanical Seal

A wave spring mechanical seal is a specialized type of seal designed to prevent leakage of fluids or gases between rotating and stationary components in mechanical systems.

Wave springs are a type of compression spring characterized by their distinctive wave-like profile. Unlike traditional coil springs, which have a circular cross-section, wave springs feature a series of waves or undulations along their length.

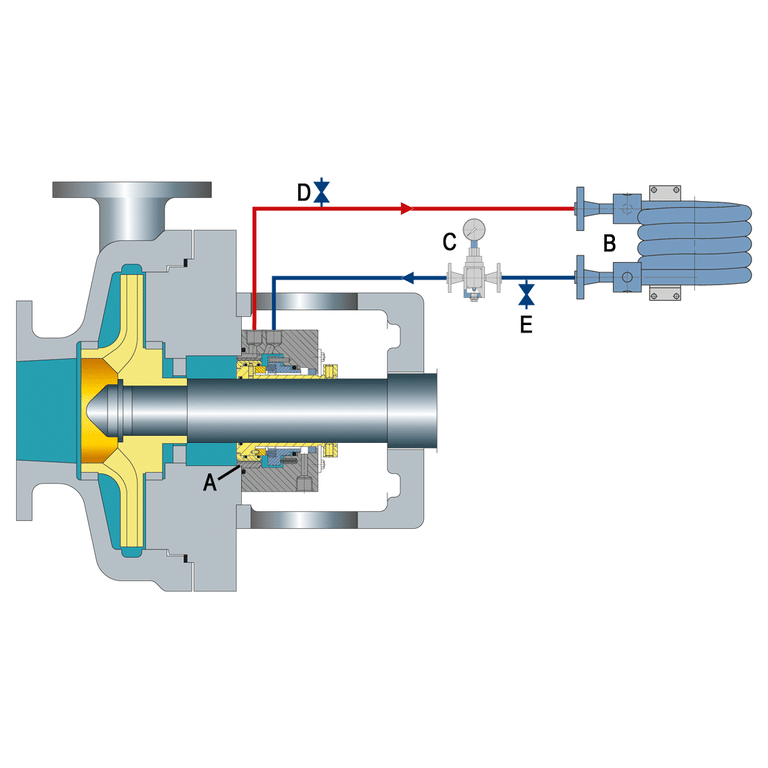

In a wave spring mechanical seal, the wave spring is typically positioned between the rotating and stationary components, such as a shaft and housing. The spring provides a constant force that maintains contact between the sealing faces, ensuring a tight, leak-proof seal. The wave spring’s design allows it to accommodate misalignment, thermal expansion, and other factors that can cause sealing faces to separate, thus maintaining seal integrity under various operating conditions.

How Wave Spring Mechanical Seals Work

Wave spring mechanical seals function by utilizing a wave spring to maintain consistent contact between the seal faces. The wave spring, a type of compression spring with a unique wave-like profile, is designed to provide a nearly constant force over a wide range of deflection.

In a typical wave spring mechanical seal, the wave spring is positioned behind the primary ring. The wave spring applies a controlled amount of axial force to the primary ring, pressing it against the mating ring.

The axial force generated by the wave spring ensures that the seal faces remain in close contact, even under varying operating conditions such as temperature fluctuations, pressure changes, and mechanical vibrations. This constant contact between the seal faces prevents leakage by creating a tight seal between the rotating and stationary components of the mechanical seal.

Advantages of Wave Spring Mechanical Seals

Consistent Sealing Force

One of the primary advantages of wave spring mechanical seals is their ability to maintain a consistent sealing force. The wave spring provides a constant force that keeps the sealing faces in close contact, regardless of any axial movement or misalignment. This consistency helps to prevent leakage and ensures reliable sealing performance over time.

Improved Tolerance to Misalignment

Wave spring mechanical seals are designed to accommodate a certain degree of misalignment between the rotating and stationary components. The flexibility of the wave spring allows it to compress and expand as needed, compensating for any angular or radial misalignment.

Reduced Wear and Longer Seal Life

The consistent sealing force provided by the wave spring helps to minimize wear on the sealing faces. By maintaining proper contact between the faces, the wave spring reduces the likelihood of excessive wear or damage caused by uneven contact or vibration.

Applications of Wave Spring Mechanical Seals

Pumps and Rotating Equipment

Wave spring mechanical seals are commonly used in pumps and other rotating equipment to prevent leakage of liquids or gases. They are particularly well-suited for applications where axial movement or misalignment is expected, such as in pumps with varying operating conditions or those subjected to thermal expansion.

Chemical Processing and Refining

In chemical processing and refining industries, wave spring mechanical seals are employed to contain hazardous or corrosive fluids. The durable materials used in the sealing faces, combined with the consistent sealing force provided by the wave spring, make these seals an ideal choice for demanding chemical applications.

Oil and Gas Industry

Wave spring mechanical seals find extensive use in the oil and gas industry. They are used in various equipment, such as pumps, compressors, and turbines, to seal oil, gas, and other fluids under high pressure and temperature conditions.

Food and Beverage Processing

In the food and beverage industry, wave spring mechanical seals are used in processing equipment to maintain hygienic conditions and prevent contamination. The seals are designed to withstand frequent cleaning and sterilization processes while providing consistent sealing performance to meet strict hygiene standards.