Aramid packing, a high-performance material derived from aramid fibers, has gained significant attention in various industries due to its exceptional properties. This versatile packing solution offers superior resistance to heat, chemicals, and abrasion, making it an ideal choice for demanding industrial applications.

In this blog post, we will delve into the world of aramid packing, exploring its unique properties and diverse applications across industries. We will also discuss key considerations for installation and maintenance to ensure optimal performance and longevity of aramid packing in industrial settings.

What Is Aramid Packing

Aramid packing is a type of mechanical seal made from synthetic aramid fibers. These fibers, such as Kevlar and Nomex, are known for their exceptional strength, heat resistance, and chemical stability. .

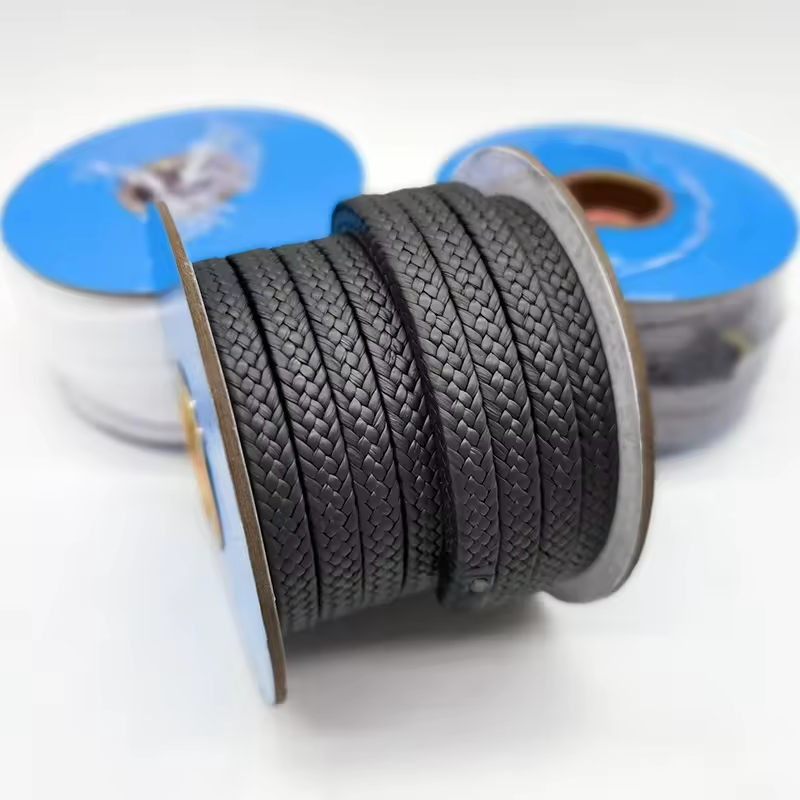

The aramid fibers used in packing are typically braided, twisted, or woven into a dense, flexible structure. This construction allows the packing to conform to the shape of the sealing surfaces, creating a tight seal that prevents leakage of fluids or gases. The interlocking nature of the fibers also enhances the packing’s resistance to extrusion and blow-out under high-pressure conditions.

Properties of Aramid Fibers

- High tensile strength: Aramid fibers exhibit excellent tensile strength, making them resistant to tearing and abrasion.

- Heat resistance: Aramid packing can withstand high temperatures, typically up to 300°C (572°F), making it suitable for high-temperature applications.

- Chemical resistance: Aramid fibers are resistant to a wide range of chemicals, including acids, alkalis, and solvents, ensuring durability in harsh environments.

- Low friction: Aramid packing has a low coefficient of friction, reducing wear on rotating equipment and improving energy efficiency.

- Non-flammability: Aramid fibers are inherently non-flammable, providing an added level of safety in fire-prone environments.

Applications of Aramid Packing

Pumps

Aramid packing is widely used in various types of pumps, including centrifugal, reciprocating, and rotary pumps. It provides an effective seal between the pump shaft and housing, preventing fluid leakage and maintaining pump efficiency.

Valves

In valve applications, aramid packing is used to seal the stem and prevent leakage of process fluids. It is particularly useful in high-temperature and high-pressure valve applications, where its strength and heat resistance are critical.

Mixers and Agitators

Aramid packing is employed in mixers and agitators to seal the shaft and prevent the escape of process materials. Its chemical resistance and durability make it suitable for sealing applications involving corrosive or abrasive substances.

Refineries and Chemical Processing

The chemical stability and heat resistance of aramid packing make it an ideal choice for sealing equipment in refineries and chemical processing plants. It can withstand exposure to a wide range of chemicals and high temperatures, ensuring reliable performance in demanding environments.