In mechanical seals, bellows are flexible, accordion-like components that act as both a sealing element and a spring.

Unlike traditional seals, which use coil springs, bellows replace these springs, forming a flexible barrier that ensures a tight seal between moving parts. The bellows design accommodates shifts in shaft position, temperature fluctuations, and vibration, maintaining a constant seal between the rotating and stationary faces.

By eliminating sliding secondary O-rings, bellows reduce the risk of shaft wear and leakage, providing better durability in demanding environments.

Types of Bellows in Mechanical Seals

Mechanical seals feature three main types of bellows: metal bellows, elastomer (rubber) bellows, and PTFE bellows. Each type has distinct benefits, making them suitable for specific applications.

Metal Bellows

Metal bellows are crafted from materials like stainless steel or nickel alloys. These bellows can handle high temperatures and harsh chemicals, making them ideal for high-pressure environments where elastomer seals might fail. Metal bellows also offer increased durability, with the ability to withstand vibration and axial movement.

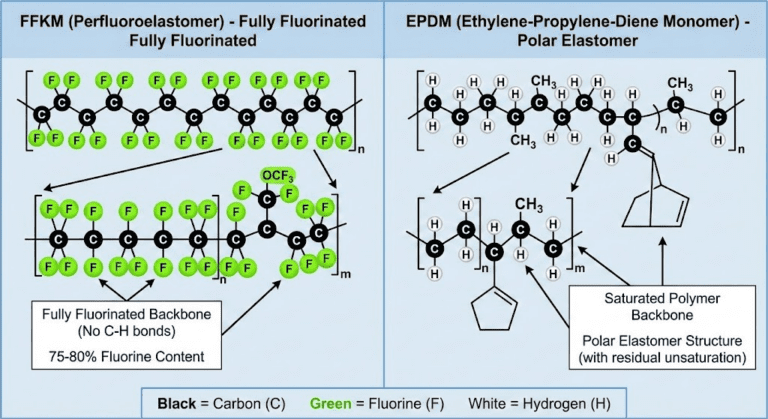

Elastomer (Rubber) Bellows

Elastomer bellows are made from synthetic rubbers such as Nitrile or EPDM. These bellows are flexible and cost-effective, making them a common choice in standard water pumps or low-pressure systems. While elastomer bellows are ideal for moderate temperature ranges, they have limitations in extreme conditions and chemical exposure.

PTFE Bellows

PTFE bellows are made from Polytetrafluoroethylene (Teflon), offering excellent chemical resistance. These bellows are commonly used in applications that require ultra-pure environments or deal with highly corrosive substances. PTFE bellows are ideal for industries like pharmaceuticals, food processing, and semiconductor manufacturing.

How to Select Bellows

Selecting the right bellows depends on several factors, including the application’s temperature range, fluid chemical properties, pressure, shaft speed, vibration, cleanliness, and cost.

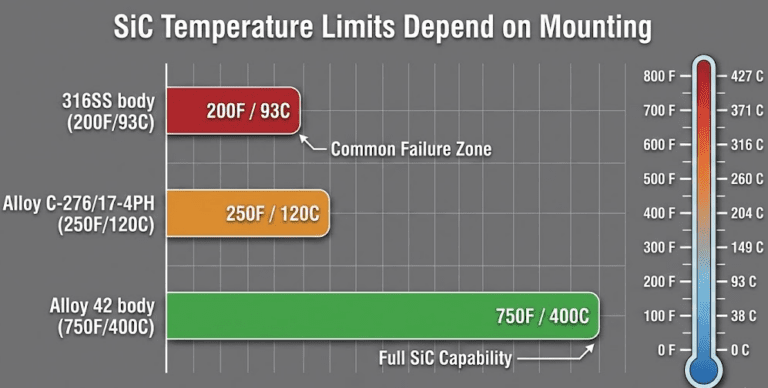

Temperature Range

Choose metal bellows for extreme temperatures, both high and low. Elastomer bellows are suitable for moderate temperature ranges, while PTFE bellows are best for environments requiring high chemical resistance.

Fluid Chemical Properties

For aggressive or corrosive fluids, metal or PTFE bellows are ideal. Elastomer bellows are suitable for water, oils, and mild chemicals, but they cannot handle harsh solvents or acids.

Pressure

Consider pressure limits when selecting bellows. Metal bellows handle higher pressures compared to elastomer bellows, which are better suited for low-pressure applications.

Shaft Speed

For high-speed applications, metal bellows perform better due to their ability to absorb shaft movement without slipping. Elastomer bellows may struggle with high shaft speeds.

Vibration

Metal bellows excel in environments with high vibration or misalignment, as they are more flexible and can absorb mechanical shocks effectively.

Cleanliness

PTFE bellows are preferred for applications requiring high cleanliness, such as in the pharmaceutical or food industries, due to their ease of cleaning and non-reactive nature.

Cost

Elastomer bellows are cost-effective and suitable for standard applications. For more demanding environments, though, investing in metal or PTFE bellows may be necessary to ensure long-term performance and reliability.