Linear valves are essential components in various industrial applications, controlling the flow of liquids and gases with precise actuation. This comprehensive article explores the world of linear valves, covering their working principles, types, actuators, advantages, disadvantages, and applications.

What Is Linear Valve

A linear valve is a type of valve that controls the flow of a fluid by moving a closure element, such as a plug or disc, in a straight line perpendicular to the flow path. Unlike rotary valves that use a rotating motion, linear valves employ a sliding stem to position the closure element and regulate the flow.

Linear valves are known for their precise flow control, especially at low flow rates, and their ability to provide reliable shutoff.

How Linear Valves Work

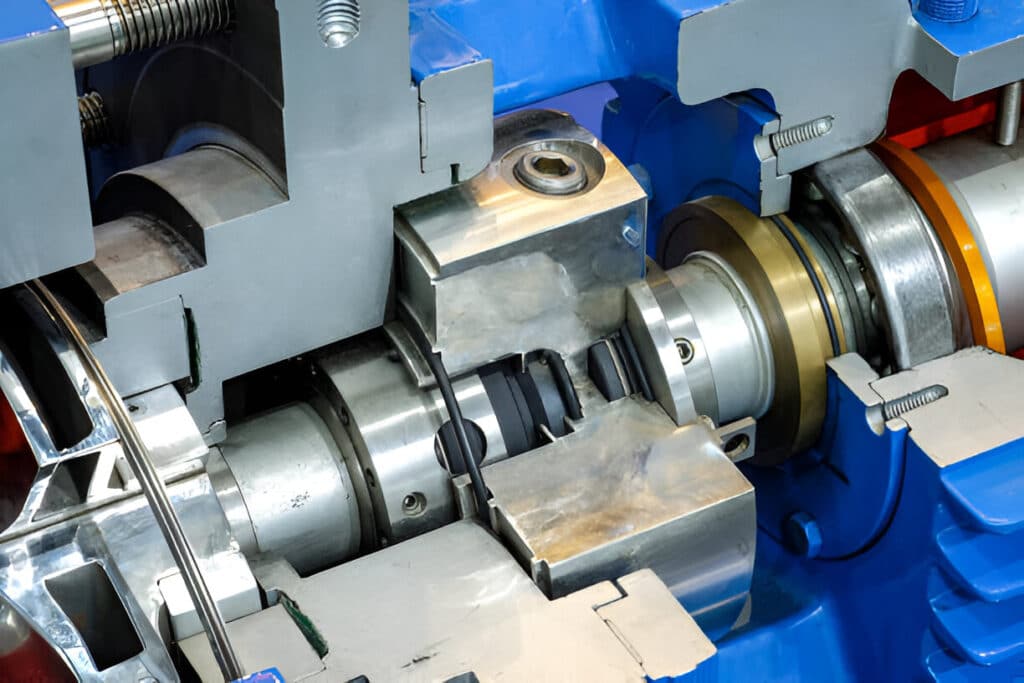

Linear valves operate by moving a closure element, typically a plug or disc, back and forth in a straight line to open, close, or throttle the flow passage. This linear motion is achieved through a sliding stem that is actuated by a manual, pneumatic, electric, or hydraulic actuator.

As the stem moves, it positions the closure element relative to the valve seat, thereby controlling the flow rate. The seating surfaces between the closure element and the valve seat provide a tight seal when the valve is closed, preventing leakage.

Types of Linear Valves

Globe Valves

Globe valves are characterized by their spherical body shape and the use of a plug-type closure element. They provide excellent throttling capabilities and are suitable for applications requiring frequent operation and precise flow control. Globe valves are commonly used in steam and water services, as well as in chemical processing and power generation plants.

Gate Valves

Gate valves feature a rectangular or wedge-shaped gate that moves up and down to open or close the flow passage. They are designed for on-off service and provide minimal resistance to flow when fully open. Gate valves are often used in applications requiring tight shutoff, such as in oil and gas pipelines, water distribution systems, and industrial process lines.

Diaphragm Valves

Diaphragm valves use a flexible diaphragm as the closure element, which is actuated by a compressor to control the flow. They provide excellent sealing performance and are suitable for handling corrosive, abrasive, or viscous fluids. Diaphragm valves are commonly found in chemical processing, pharmaceutical, and food and beverage industries.

Pinch Valves

Pinch valves have a flexible sleeve or tube that is pinched by a mechanical mechanism to restrict or stop the flow. They are ideal for handling slurries, powders, and other abrasive or corrosive media, as the valve body is isolated from the process fluid. Pinch valves are widely used in mining, wastewater treatment, and pneumatic conveying applications.

Needle Valves

Needle valves feature a slender, tapered plug that provides fine flow control by varying the annular opening between the plug and the seat. They are designed for precise throttling of low flow rates and are commonly used in instrumentation, sampling, and metering applications.

Types of Linear Motion Valve

In addition to the different valve types, linear motion valves can be categorized based on their valve body configuration:

Single Port Valve Body

Single port valve bodies have one inlet and one outlet port, with the closure element positioned between them. This configuration is the most common and is suitable for most general-purpose applications.

Double Port Valve Body

Double port valve bodies have two separate flow paths, each with its own closure element. This design allows for greater flow capacity and reduced pressure drop compared to single port valves. Double port valves are often used in high-flow applications or where redundancy is required.

Three-way Valve Body

Three-way valve bodies have three ports, allowing for the mixing or diverting of flow streams. They are commonly used in temperature control systems, such as in heat exchangers or HVAC applications, where a fluid can be directed to either a heating or cooling circuit.

Linear Valve Actuators

Linear valve actuators are the devices that provide the motive force to operate the valve stem and position the closure element.

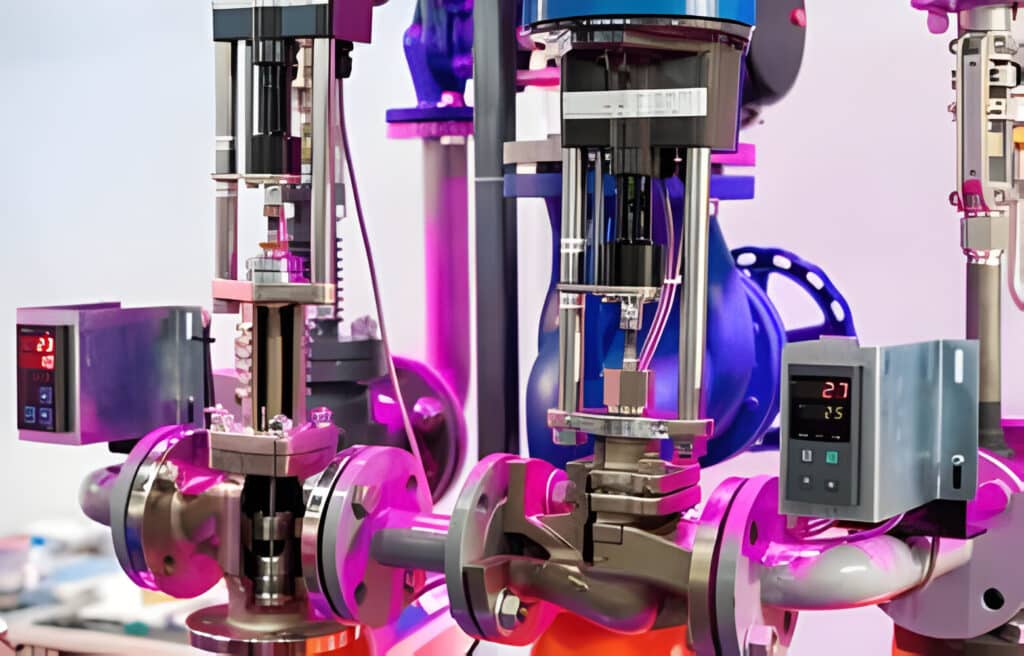

Pneumatic Actuators

Pneumatic actuators use compressed air to drive the valve stem, providing a simple and reliable actuation method. They are suitable for applications requiring fast response times and are commonly used in process control and automation systems.

Electric Actuators

Electric actuators use an electric motor and gear train to convert rotary motion into linear motion, driving the valve stem. They offer precise positioning control and are suitable for applications requiring accurate and repeatable flow control. Electric actuators are widely used in industrial automation, HVAC systems, and water treatment plants.

Hydraulic Actuators

Hydraulic actuators use pressurized hydraulic fluid to provide the motive force for the valve stem. They are capable of generating high thrust forces and are suitable for applications requiring large valve sizes or high pressure differentials. Hydraulic actuators are commonly found in oil and gas, power generation, and marine applications.

Electro-Hydraulic Actuators

Electro-hydraulic actuators combine the advantages of electric and hydraulic actuation, using an electric motor to drive a hydraulic pump that generates the necessary fluid pressure. They provide precise control and high thrust capabilities, making them suitable for demanding applications in process control and aerospace industries.

Advantages of Linear Valves

Linear valves offer several advantages over other valve types:

- Precise Flow Control, Especially at Low Flow Rates

- Reliable Shutoff

- Resistance to Cavitation Compared to Rotary Valves

- Maintainability

Disadvantages of Linear Valves

Despite their many advantages, linear valves also have some drawbacks:

- Slower Actuation Compared to Rotary Valves

- Larger Size and Higher Cost Than Rotary Valves

- Potential for Seat Leakage

Applications

Linear valves find use in a wide range of industries and applications, including:

- Liquid Level Control

- Flow Control Requiring Constant Gain

- Temperature Control (E.G. Heat Exchangers)

- High Pressure Drop Applications

- Frequent On/Off Service

FAQs

What Is Linear Valve Offset

Linear valve offset refers to the distance between the centerline of the valve stem and the centerline of the valve body or seating surface. This offset allows for better flow characteristics and reduces wear on the seating surfaces compared to in-line designs.

What Is Linear Control Valve

A linear control valve is a type of linear valve specifically designed for precise control of process variables, such as flow rate, pressure, or temperature. They typically feature a characterized trim and a positioner for accurate and repeatable positioning of the closure element.

What Is Linear Motion Valve

A linear motion valve is a valve that uses a linear actuator to move the closure element in a straight line, perpendicular to the flow path, to control the flow. This is in contrast to rotary motion valves, which use a rotating motion to position the closure element.

What Is a Linear Expansion Valve

A linear expansion valve is a type of refrigeration control valve that regulates the flow of refrigerant into the evaporator based on the temperature and pressure of the refrigerant leaving the evaporator. It maintains a constant superheat at the evaporator outlet, ensuring optimal system performance.

What Is a Linear Solenoid Valve

A linear solenoid valve is a valve that uses a solenoid coil to generate a magnetic field, which actuates a plunger or armature to open or close the valve. Linear solenoid valves provide fast response times and are commonly used in pneumatic and hydraulic control systems.

What Is the Difference between Linear and Nonlinear Valves?

Linear valves have a closure element that moves in a straight line, providing a flow rate that is directly proportional to the valve travel. Nonlinear valves, such as rotary valves or characterized control valves, have a non-linear relationship between valve travel and flow rate, allowing for more precise control over a wider range of flow conditions.

What Is Rotary vs Linear Valves?

Rotary valves use a rotating motion to position the closure element, typically a ball, disc, or plug, to control the flow. Linear valves, on the other hand, use a linear motion to move the closure element, usually a globe or gate, in a straight line perpendicular to the flow path. Rotary valves are generally more compact and have faster actuation speeds, while linear valves provide better throttling capabilities and sealing performance.

What Is the Difference between Linear and Equal Control Valves?

Linear control valves have a linear relationship between valve travel and flow rate, meaning that a change in valve position results in a proportional change in flow rate. Equal percentage control valves have a non-linear relationship, where the change in flow rate is proportional to the current flow rate, providing more precise control over a wider range of flow conditions.

Conclusion

Linear valves are vital components in various industrial applications, offering precise flow control, reliable shutoff, and resistance to cavitation. With a range of valve types, actuators, and body configurations, linear valves can be tailored to meet the specific requirements of different industries and applications.

By understanding the working principles, advantages, and limitations of linear valves, engineers and technicians can select the most appropriate valve for their flow control needs, ensuring optimal system performance and reliability.