Have you ever wondered what a slurry pump is and how it works? A slurry pump is a type of pump designed to move slurry, a mixture of solid particles suspended in a liquid.

Slurry pumps are essential in various industries, such as mining, construction, and wastewater treatment, where moving abrasive and corrosive materials is necessary. In this blog post, we’ll dive deeper into the slurry pumps.

What is a Slurry

A slurry refers to a mixture of solid particles suspended in a liquid medium. This combination creates a thick, viscous fluid with unique properties.

The consistency of a slurry depends on the ratio of solids to liquid. Higher solid content results in a thicker, more paste-like mixture.

Properties of Slurry

- Abrasive Nature: Contains abrasive solid particles, causing significant wear on pumping equipment.

- Consistency Variability: Ranges from thin and watery to thick and paste-like, affecting flow behavior and pumping requirements.

- High Specific Gravity: Dense solid materials require more power to transport.

- High Viscosity: Affects flow characteristics, requiring pumps to overcome resistance for efficient operation.

- Fluctuating Solid Content: Pumps must handle varying concentrations to maintain consistent performance.

- Quick Settling: Tends to settle quickly when flow stops, requiring pumps to prevent clogging and ensure proper flow resumption.

Types of Slurry

- Settling Slurry: Contains coarse, heavy particles that quickly settle out of suspension when not in motion.

- Non-Settling Slurry: Consists of fine particles that remain suspended in the liquid, even when the flow stops.

- Viscous Slurry: A thick, paste-like mixture that resists flow and requires specialized pumping equipment.

- Froth Slurry: Contains a significant amount of entrained air or gas, creating a foamy consistency.

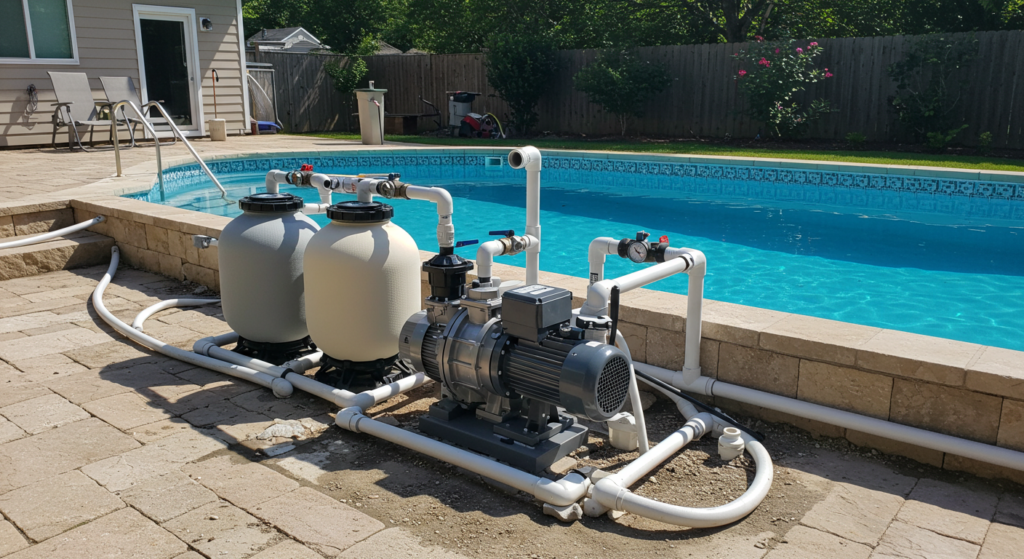

What is Slurry Pump

A slurry pump is a type of pump designed to handle abrasive slurries containing solid particles suspended in a liquid. These pumps are built with durable materials like chrome alloy steel to withstand the harsh conditions caused by abrasive particles and corrosive chemicals.

How Slurry Pumps Work

Slurry pumps operate by moving mixtures of solids and liquids through piping systems.

The pump’s impeller rotates at high speeds within the pump casing. This rotation creates centrifugal force, which propels the slurry outward.

As the slurry moves outward, it gains kinetic energy. This energy translates into pressure, pushing the mixture through the pump’s discharge.

Key Components of a Slurry Pump

- Impeller: The impeller is a critical component of a slurry pump, designed to handle abrasive slurries and solid particles.

- Pump casing: The pump casing houses the impeller and provides a path for the slurry to flow through the pump.

- Shaft and bearing assembly: The shaft and bearing assembly support the impeller and transfer power from the motor to the impeller.

- Shaft seals: Shaft seals prevent leakage of the slurry along the shaft and protect the bearings from contamination.

- Liners: Liners are replaceable components installed inside the pump casing to protect it from abrasion and extend the life of the pump.

- Drive type: Slurry pumps can be driven by electric motors, hydraulic motors, or diesel engines.

Types of Slurry Pumps

Horizontal Slurry Pumps

Horizontal slurry pumps are capable of handling a wide range of particle sizes and solids concentrations, making them suitable for various industries such as mining, chemical processing, and wastewater treatment.

With their efficient slurry design impeller and optimized flow properties, horizontal slurry pumps deliver superior performance and uniform delivery of the slurry.

Vertical/Tank Pumps

Vertical/tank pumps are a type of slurry pump designed for applications where the pump needs to be submerged in the slurry or mounted on top of a tank. These pumps feature a vertical shaft and are commonly used in industries such as mining, chemical processing, and wastewater treatment.

The design of vertical/tank pumps allows for efficient handling of slurries with high concentrations of solid particles. These pumps offer advantages such as ease of maintenance, uniform delivery of the slurry, and the ability to handle a wide range of particle sizes.

Submersible Slurry Pumps

Submersible slurry pumps are capable of handling a wide range of particle sizes and concentrations of solids, making them suitable for various industrial applications such as mining, dredging, and wastewater treatment.

Submersible slurry pumps offer superior performance, uniform delivery, and ease of maintenance, resulting in lower operational costs. With their ability to handle complex tasks and aggressive dewatering applications, these pumps provide an efficient solution for pumping abrasive slurries in harsh environments.

Froth Pumps

Froth pumps are a specialized type of slurry pump designed to handle fluids with high concentrations of air or gas bubbles. These pumps are commonly used in industries such as mining, wastewater treatment, and chemical processing, where froth or foam is a byproduct of the process.

The design of froth pumps incorporates features that allow them to effectively handle the unique properties of froth, such as its low density and high compressibility. These pumps typically have larger impellers and volutes compared to standard slurry pumps, which helps to minimize the risk of cavitation and ensure efficient pumping performance.

Factors in Selecting a Slurry Pump

Slurry Properties

Slurry properties, such as particle size, concentration, abrasiveness, and corrosiveness, play a crucial role in selecting the appropriate slurry pump for a given application.

Slurry pumps are designed to handle a wide range of particle sizes, from fine to coarse, depending on the specific application requirements. The concentration of solids in the slurry also affects pump performance, with higher concentrations requiring specialized designs to prevent clogging and ensure efficient operation.

Abrasive slurries, containing hard particles like sand or gravel, can cause significant wear on pump components, necessitating the use of abrasion-resistant materials such as chrome alloy steel or elastomeric liners. Corrosive slurries, on the other hand, may contain chemicals that can degrade pump materials, requiring the selection of corrosion-resistant alloys or special coatings to extend the pump’s service life.

Required Flow Rate, Head, and Efficiency

The required flow rate, head, and efficiency are crucial factors in selecting the right slurry pump for a specific application.

The flow rate determines the volume of slurry that can be transported over a given time, while the head refers to the pressure the pump must overcome to move the slurry to the desired destination.

Efficiency is a measure of how well the pump converts input power into useful work, and it directly impacts the pump’s operating costs.

Pump Materials of Construction

The materials used in the construction of slurry pumps, particularly for wetted parts and wear components, are crucial for ensuring reliable performance and extended wear life in abrasive slurry applications. These pumps are designed to handle fluids containing solid particles, which can cause significant wear and tear on the pump’s internal components.

Common materials used for slurry pump construction include chrome alloy steel, elastomeric materials, and other hard-wearing, corrosion-resistant materials.

Key components, such as the pump casing, impeller, and shaft sleeve, are often constructed with extra metal thickness to withstand the abrasive conditions. Additionally, wear liners and other replaceable wear components are designed for ease of maintenance, helping to minimize operational costs and extend the pump’s overall life.

Pump Size

Pump size is typically determined by the flow rate and discharge pressure required for the task at hand.

Larger pumps are capable of handling higher flow rates and discharge pressures, making them suitable for heavy-duty applications involving large volumes of slurry or high-pressure discharge requirements. Smaller pumps, on the other hand, are more appropriate for applications with lower flow rates and discharge pressures.

The size of the pump also affects its power consumption, with larger pumps generally requiring more power to operate efficiently.

Pump Operating Parameters

The discharge pressure, flow rate, and power requirements are essential considerations in selecting the appropriate slurry pump.

Impeller Type

Open impellers are suitable for slurries with large particle sizes and high concentrations of solids, as they allow the passage of these particles without clogging.

Closed impellers are ideal for slurries with smaller particle sizes and lower concentrations of solids, as they provide better efficiency and wear resistance.

Vortex impellers, also known as recessed impellers, are designed for slurries with extremely abrasive particles or high concentrations of solids.

Ease of Maintenance and Parts Replacement

Slurry pumps are designed with ease of maintenance and parts replacement in mind. The front-loading design allows for quick and easy access to the seal and other critical components.

When it comes to parts replacement, slurry pumps often utilize common metal alloys and corrosion-resistant materials to ensure availability and cost-effectiveness.

Slurry Pump Applications

- Mining: Slurry pumps are essential in mining applications for transporting abrasive materials, such as ore slurries, tailings, and heavy-duty slurries with high solids concentrations.

- Construction: In construction projects, slurry pumps are used for pumping concrete, grout, and other abrasive fluids containing solid particles.

- Wastewater Treatment: Slurry pumps play a crucial role in wastewater treatment industries, handling sludge, sewage, and other challenging fluids with ease.

- Chemical Processing: These pumps are employed in chemical processing plants to transport corrosive chemicals, slurries, and mixtures with abrasive particles.

- Power Generation: Slurry pumps are utilized in power generation facilities for handling coal slurries, ash handling, and other abrasive applications.

- Dredging: Dredge pumps, a type of slurry pump, are used in aggressive dewatering and slurry applications, efficiently moving solids-laden fluids.

FAQs

What is the difference between a slurry pump and a water pump?

Slurry pumps are built to handle abrasive mixtures, featuring tougher materials and designs that resist wear. They also have larger clearances to allow solid particles to pass through without clogging.

What are the disadvantages of slurry pump?

Slurry pumps are prone to wear and abrasion. They require frequent maintenance and part replacements. High energy consumption is common. Handling viscous materials can be challenging. Clogging issues may occur with larger particles.

In Conclusion

In conclusion, slurry pumps are essential for transporting abrasive and corrosive mixtures efficiently in various industries. Choosing the right slurry pump based on the application and material properties is crucial for optimal performance and longevity.

For more information on selecting the best slurry pump for your needs, consult with a trusted supplier today.