If you work with industrial equipment, steam systems, or pump maintenance, you’ve probably heard both terms thrown around. The problem? Most people treat them as interchangeable. They’re not. A seal pot and a condensate pot are fundamentally different devices that solve completely different problems.

Think of it this way: a seal pot is like a bodyguard protecting your pump from toxic chemicals, while a condensate pot is like a translator ensuring your measurement instruments understand what the steam is trying to tell them. Both are essential in their own contexts, but confusing them can wreck your equipment and give you false readings.

Understanding Seal Pots

A seal pot is a pressurized reservoir that supplies and maintains barrier fluid for double mechanical seals in pumps and rotating equipment. When hazardous, toxic, or flammable fluids flow through your pump, a seal pot is your first line of defense against environmental contamination.

Here’s the problem a seal pot solves: mechanical seals have a weak point. The shaft has to rotate, which means the seal faces must be in constant contact. But contact means friction, and friction means tiny amounts of process fluid can leak into the environment. In many industries, this isn’t just bad—it’s catastrophic. Toxic chemicals escaping into the air, hazardous fumes, regulatory violations, environmental damage.

A seal pot stops this cold.

How Seal Pots Actually Work

The magic happens through pressure control. The seal pot maintains a barrier fluid at a pressure that’s always 15 to 25 psi higher than the process fluid pressure inside the pump. This positive pressure creates an invisible shield.

If any leakage happens at the inner seal faces, it’s the clean barrier fluid that leaks into the process, not process fluid leaking out into the environment. The barrier fluid also lubricates those seal faces constantly, keeping them cool and preventing the metal-on-metal contact that would destroy the seal in seconds.

The barrier fluid circulates continuously through the seal pot and back to the seal chamber. Some systems do this passively through thermosiphon circulation, where temperature differences naturally move the fluid. Larger, more demanding equipment uses mechanical pumps to push the fluid through faster and provide better cooling.

Where You’ll Find Seal Pots

Seal pots show up in industries where fluid containment is non-negotiable. Chemical plants use them on pumps handling corrosive or toxic chemicals. Refineries depend on them to keep flammable hydrocarbons contained. Pharmaceutical manufacturers rely on them to prevent process fluid contamination. Even food and beverage companies use seal pots to maintain product purity and safety.

If a pump is handling something you wouldn’t want spilled on your shirt, it probably needs a seal pot.

Understanding Condensate Pots: The Translator for Your Instruments

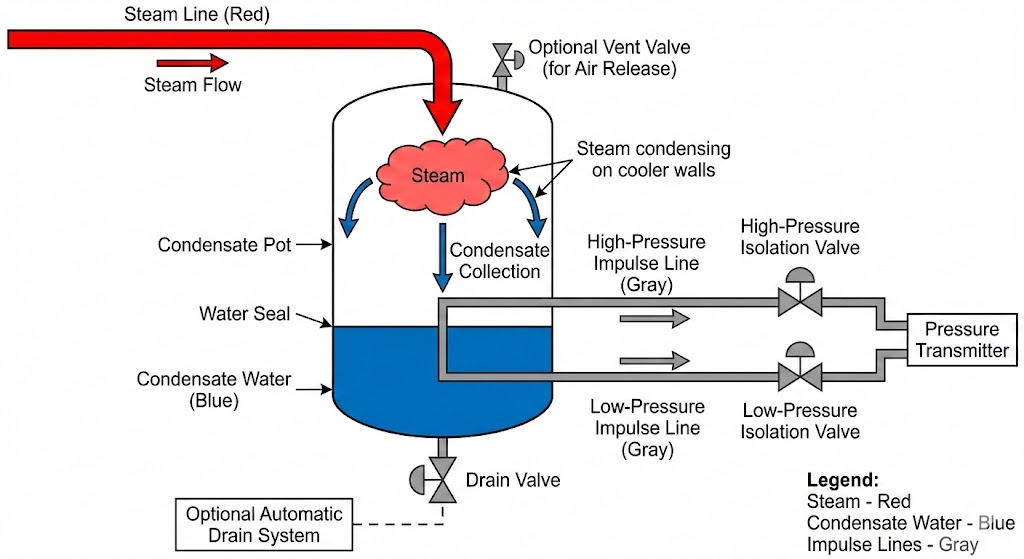

Now flip to the complete opposite end of the spectrum. A condensate pot, also called a steam condensate pot or condensate seal pot, solves a measurement problem, not a containment problem.

Here’s the challenge: when you want to measure steam pressure, you need accurate readings. But steam is a vapor. When that vapor travels through impulse lines to your pressure transmitter, something messy happens—it condenses at different rates in different places. One part of the line might still have steam. Another part might be full of water. Your transmitter gets confused and gives you wildly inaccurate readings.

A condensate pot fixes this by ensuring that only liquid water reaches your pressure transmitter, not steam vapor.

How Condensate Pots Actually Work

The principle is simple but brilliant. Steam enters the condensate pot and immediately hits a cooler environment. The temperature drop causes the steam to condense into liquid water. This water pools at the bottom of the pot, creating a hydrostatic seal.

Think of it as a dam made of water. On one side, you have steam trying to push into the impulse line. On the other side, you have the pressure transmitter. The water seal sits between them like a bouncer at a nightclub—it lets the pressure signal through but keeps the steam out.

This water seal ensures that only the pressure of the liquid (not the vapor) reaches your transmitter. No more random condensation happening at random places along your impulse lines. Your pressure reading becomes consistent and accurate.

Where Condensate Pots Are Used

Anywhere steam is measured, condensate pots keep things honest. You’ll find them in steam distribution systems measuring flow rates. Heat exchanger condensate collection systems use them. Industrial boiler systems depend on them for accurate pressure monitoring. Power plants, food processing facilities, and chemical plants all rely on condensate pots for accurate steam flow measurement.

If you’re trying to measure steam accurately, a condensate pot is practically mandatory.

The Critical Differences: Seal Pot Versus Condensate Pot

These aren’t just different devices. They’re opposite approaches to two completely different problems.

A seal pot is active and pressurized. It actively circulates barrier fluid, maintains a constant pressure differential, and continuously cools the seal surfaces. Condensate pots are passive. They simply collect condensate through gravity and rely on the water seal to do its job.

Seal pots handle hazardous fluids and protect the environment. They’re found in pumps and rotating equipment. Condensate pots measure steam accurately. They’re found in measurement systems and steam lines.

Seal pots operate at 15 to 25 psi above process pressure. Condensate pots operate at or near atmospheric pressure. A seal pot uses carefully selected barrier fluid—often oil, water, or glycol. A condensate pot contains water condensate from steam, nothing more.

Seal pots need constant monitoring through pressure transmitters, level switches, and temperature gauges. Condensate pots need periodic manual maintenance like draining and blowdown procedures.

Seal pots fail when pressure drops below the minimum threshold, allowing process fluid to leak into the environment. Condensate pots fail when they plug with debris or overflow when drainage systems malfunction.

The Bottom Line: Know What You’re Using

A seal pot protects your pump and your environment by maintaining pressurized barrier fluid. A condensate pot ensures your steam measurements stay accurate by collecting condensate and creating a water seal. They’re equally important in their own contexts, but they do completely different jobs.

Confusing them is one of the most common mistakes in industrial maintenance. Installing a condensate pot where you need a seal pot wastes equipment life and creates safety risks. Installing a seal pot where you need a condensate pot gives you worthless pressure readings.

Know which one you’re looking at. Know what it does. Know how to maintain it. That’s the difference between equipment that runs smoothly for years and equipment that surprises you with costly failures.