What Is a Seal Pot

A seal pot, also known as a barrier fluid reservoir system, is a critical component in mechanical seal systems used in industrial processes such as chemical plants and refineries. It provides a clean lubricating fluid to the outer seal chamber of double seals, protecting the seals from the potentially harmful process fluid.

How Does Seal Pot Work

The seal pot works by supplying a pressurized barrier fluid to the outer seal chamber of a double mechanical seal arrangement. The barrier fluid is maintained at a higher pressure than the process fluid, creating a protective buffer between the process side mechanical seal and the atmosphere. This prevents the dirty process fluid from reaching the secondary seal.

The seal pot is connected to the outer seal chamber via piping plans. When the inboard seal leaks slightly, the barrier fluid flows into the seal chamber, maintaining the pressure and lubricating the seals. Refill pumps or pressure accumulators automatically top up the seal pot to maintain the barrier fluid at the required pressure.

Components of Seal Pot

A typical seal pot assembly consists of the following key components:

- Reservoir tank: Stores the barrier fluid and is sized based on the seal chamber volume and expected leakage rates. Common materials include stainless steel and carbon steel.

- Pressure controls: Regulate the barrier fluid pressure using switches, transmitters, and valves. Maintain the pressure at 15-25 psi above the seal chamber pressure.

- Level controls: Monitor the barrier fluid level using switches or transmitters. Ensure adequate fluid is available and prevent overfilling.

- Refill valve: Allows for the addition of barrier fluid to the seal pot when the level drops below a specified point.

- Vent valve: Prevents overpressurization of the seal pot by releasing excess pressure.

- Drain valve: Facilitates the removal of barrier fluid from the seal pot for maintenance or replacement.

- Instrumentation: Includes pressure, level, and temperature transmitters for monitoring and control. May integrate with plant control systems.

Function of Seal Pot

The primary function of a seal pot is to provide a clean, cool, lubricating fluid to the outer seal chamber in double seal arrangements. This barrier fluid maintains a stable environment for the seals, reducing wear, heat generation, and corrosion.

Key functions include:

- Lubrication: The barrier fluid lubricates the seal faces, minimizing friction, heat and wear.

- Cooling: Circulation through the seal pot removes heat generated by the sealing process.

- Flushing: The higher pressure barrier fluid flushes away any process fluid leakage across the inboard seal.

- Pressure maintenance: The seal pot keeps the barrier fluid at a higher pressure than the process, preventing process fluid ingress.

- Monitoring: Instrumentation on the seal pot allows for condition monitoring of the sealing system.

What Is a Seal Pot Used for

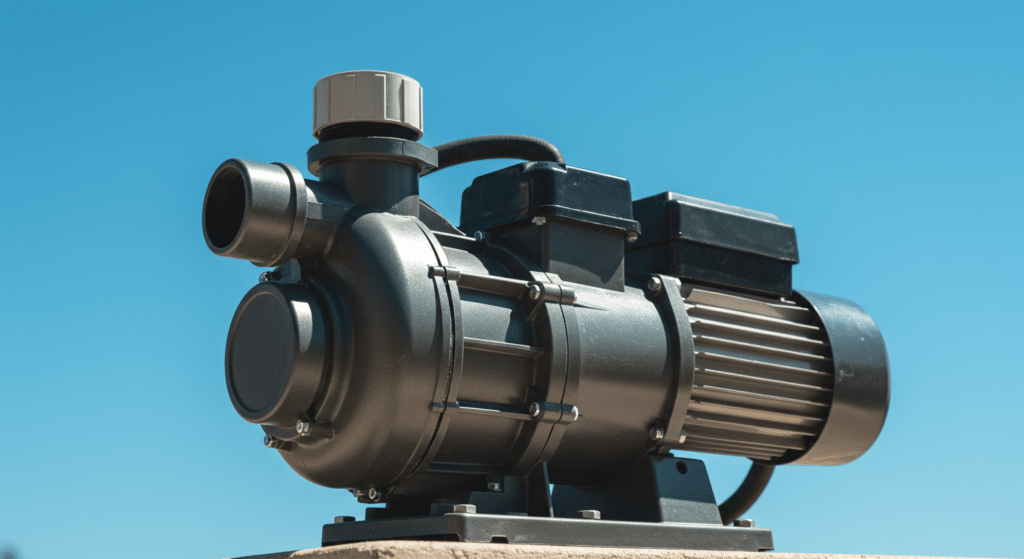

- Centrifugal pumps: Seal pots are commonly used in centrifugal pumps handling hazardous, toxic, or flammable fluids to prevent leakage and enhance pump reliability.

- Petrochemical industry: In petrochemical plants, seal pots are used in pumps and other rotating equipment to contain and control the flow of hydrocarbons and other process fluids.

- Chemical processing: Seal pots are essential in chemical plants where the containment of dangerous chemicals is crucial for safety and environmental protection.

- Pharmaceutical industry: In pharmaceutical manufacturing, seal pots help maintain the purity of the process fluids and prevent contamination.

- Food and beverage industry: Seal pots are used in food and beverage processing equipment to ensure the hygiene and safety of the products.

What Is the Difference between a Seal Pot and a Condensate Pot

Function

A seal pot is primarily used to supply barrier fluid to the mechanical seal and maintain seal chamber pressure, while a condensate pot is used to collect and remove condensate from a steam system.

Fluid handled

Seal pots typically contain barrier fluids compatible with the process fluid and the mechanical seal materials. Condensate pots, on the other hand, handle condensate from steam systems.

Instrumentation

Seal pots are equipped with level switches, pressure transmitters, and other instrumentation to monitor and control the barrier fluid. Condensate pots may have level switches and temperature sensors to monitor condensate levels and prevent equipment damage.

System integration

Seal pots are an integral part of mechanical seal systems in pumps and other rotating equipment, while condensate pots are used in steam distribution systems to improve efficiency and prevent damage caused by condensate accumulation.