Are you struggling to choose between lip seals and squeeze seals for your machinery applications? Not understanding the key differences can lead to reduced equipment performance and costly failures.

Using the wrong seal type for your specific needs will increase friction, accelerate wear, and potentially allow leaks and contaminants. This results in unplanned downtime, expensive repairs, and decreased productivity.

In this article, we’ll break down the core differences between lip seals and squeeze seals, covering critical factors like shape, sealing mechanism, friction dynamics, pressure handling, materials, and ideal use cases. By the end, you’ll have the knowledge to confidently select the optimal seal type for your machinery, maximizing reliability and service life.

What is Squeeze Seal

A squeeze seal, also known as a compression seal, is a type of seal that utilizes the compressive force applied by the mating surfaces to create a sealing effect. The seal is typically made of an elastomeric material, such as rubber or silicone, and is designed to be compressed between two surfaces. When the mating surfaces are tightened together, the squeeze seal deforms and fills any gaps or irregularities, creating a tight seal that prevents leakage.

What is Lip Seal

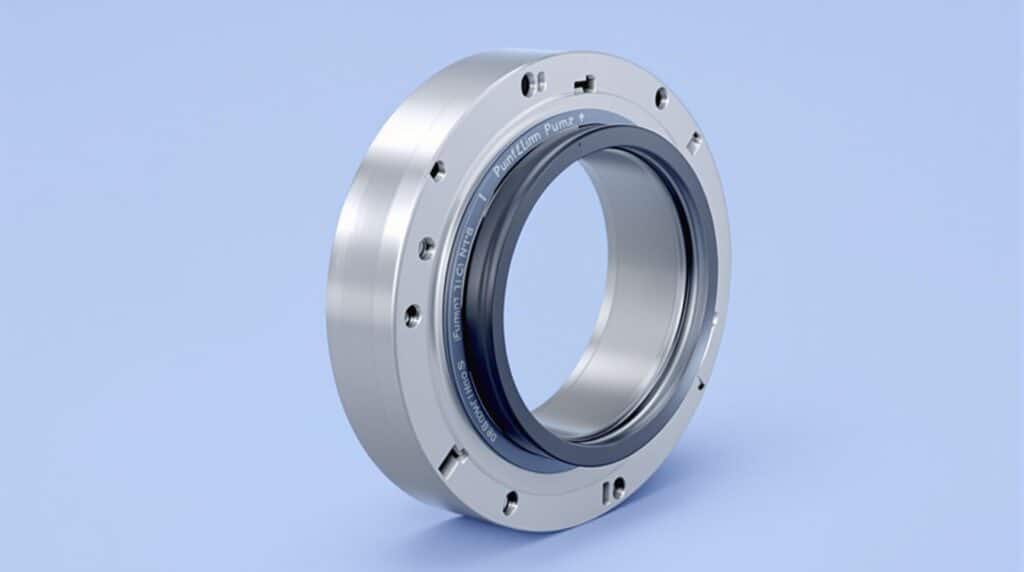

A lip seal is a type of seal that features a flexible sealing element, often referred to as a lip. The lip is designed to make contact with a moving surface, such as a rotating shaft or a reciprocating rod. The lip is typically made of a flexible material, such as rubber or polyurethane, and is molded or machined to have a specific geometry that allows it to maintain contact with the moving surface. The lip seal relies on the elasticity and flexibility of the lip to maintain a sealing effect, even in the presence of relative motion between the seal and the mating surface.

Difference Between Lip Seal and Squeeze Seal

Shape

Squeeze seals typically have a simple, rectangular cross-section and are designed to be compressed between two flat surfaces.

Lip seals have a more complex geometry, with a flexible lip that protrudes from the seal body.

Sealing Mechanism

Squeeze seals rely on the compressive force applied by the mating surfaces to create a sealing effect. As the seal is compressed, it deforms and fills any gaps or irregularities between the surfaces, preventing leakage.

Lip seals rely on the contact between the flexible lip and the moving surface to maintain a sealing effect. The lip is designed to maintain contact with the surface, even in the presence of relative motion, through its elasticity and flexibility.

Friction and Wear Dynamics

Lip seals are designed to make contact with a moving surface, which can result in friction and wear over time.

Squeeze seals do not have any moving parts and do not experience the same level of friction and wear as lip seals. However, the compressive force applied to the squeeze seal can cause deformation and compression set over time, which can affect the sealing performance.

Pressure

Squeeze seals are typically designed to handle higher pressures compared to lip seals. The compressive force applied to the squeeze seal can create a strong sealing effect, even at high pressures.

Lip seals may have limitations in terms of pressure rating due to the flexibility and elasticity of the lip material. High pressures can cause the lip to deform or become dislodged, compromising the sealing effect.

Material

Squeeze seals are commonly made of elastomeric materials, such as rubber or silicone, which provide good sealing properties and can withstand compression.

Lip seals can be made of a wider range of materials, including rubber, polyurethane, PTFE, and other engineered plastics.

Applications

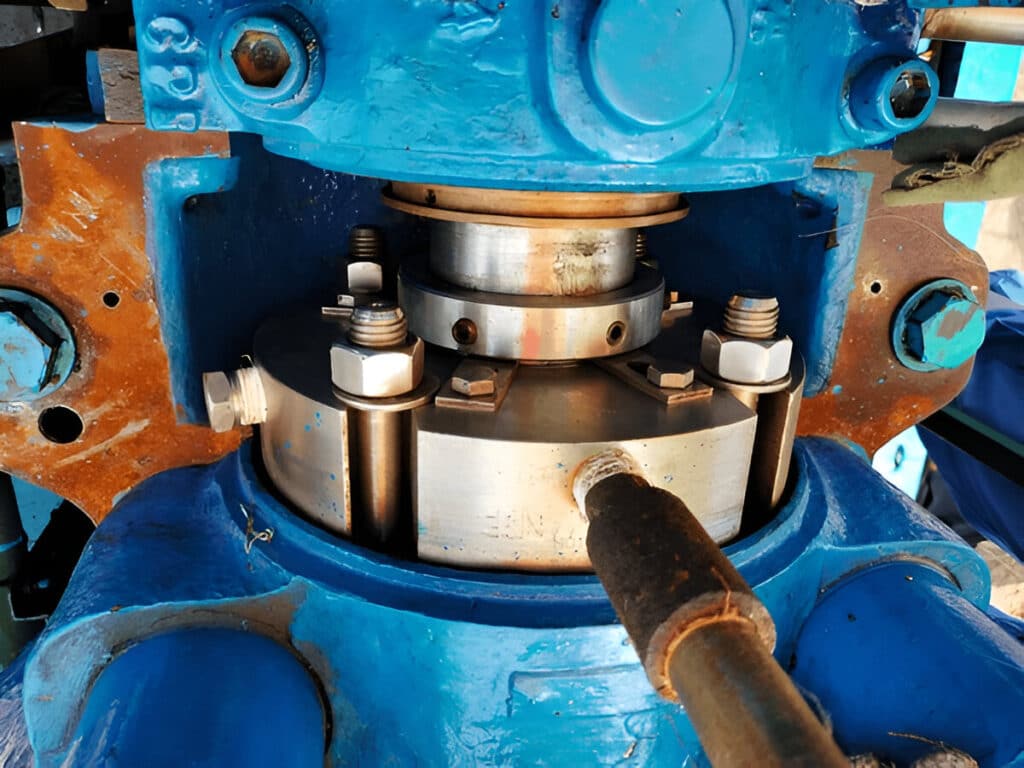

Lip seals are commonly used in applications involving rotating shafts or reciprocating rods, such as in pumps, motors, and hydraulic cylinders. They are well-suited for applications where relative motion between the seal and the mating surface is present.

Squeeze seals are often used in static sealing applications, such as in flanges, connectors, and housing interfaces. They are ideal for applications where a tight seal is required between two stationary surfaces.