What Is Plan 53a

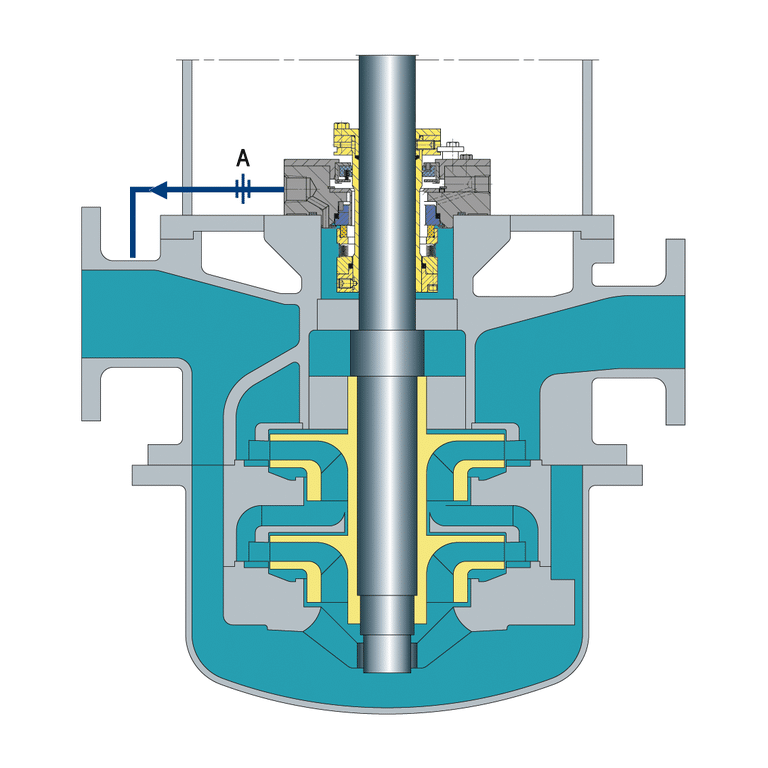

Plan 53a is a piping plan for mechanical seals that utilizes a barrier fluid reservoir to provide a clean, cool environment for the seal. The barrier fluid, typically a compatible lubricating liquid, is circulated through a closed loop system by an external pump. This plan is designed to maintain a higher pressure in the barrier fluid than the process fluid, preventing process fluid from entering the seal chamber.

The barrier fluid reservoir in Plan 53a is usually sized to hold a sufficient volume of fluid to accommodate thermal expansion and small leaks. It also includes a heat exchanger to remove excess heat generated by the mechanical seal and maintain a stable barrier fluid temperature. Pressure accumulator and regulating valves are employed to control the barrier fluid pressure, ensuring it remains higher than the process fluid pressure.

What Is Plan 54

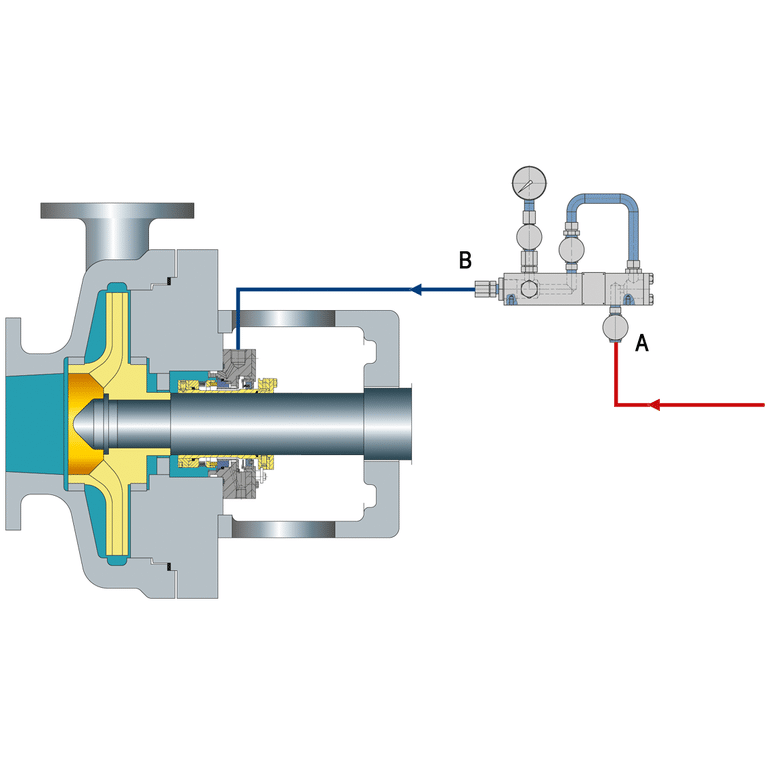

Plan 54 is a more advanced piping plan that builds upon the principles of Plan 53a. It incorporates a pressurized external barrier fluid reservoir with a bladder accumulator to provide a higher degree of pressure control and reliability. The bladder accumulator maintains a constant pressure in the barrier fluid system, compensating for volumetric changes due to thermal expansion or minor leaks.

In Plan 54, the barrier fluid is circulated through the mechanical seal by an external pump, similar to Plan 53a. However, the addition of the bladder accumulator allows for more precise pressure regulation and a quicker response to pressure fluctuations. The bladder accumulator also helps to minimize the amount of barrier fluid required, as it can accommodate the expansion and contraction of the fluid without needing a large reservoir.

Key Differences between Plan 53a and 54

Circulation and Heat Dissipation

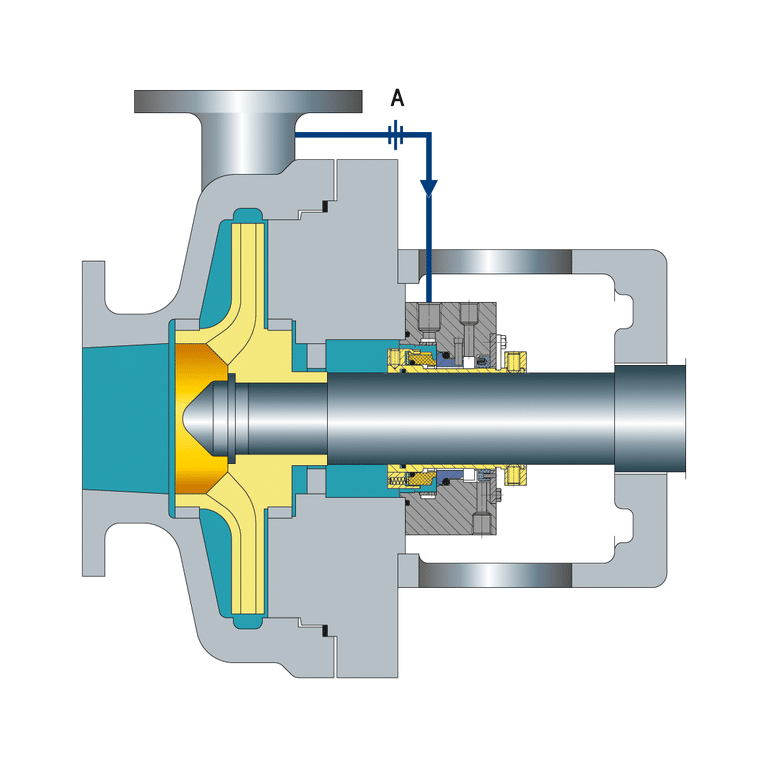

Both Plan 53a and Plan 54 utilize an external circulation system to provide a clean, cool barrier fluid to the mechanical seal. The circulation helps to remove heat generated by the seal faces and maintain a stable operating temperature. However, Plan 54 often incorporates a more efficient heat exchanger and circulation system, as the pressurized nature of the system allows for better heat transfer and temperature control.

Pressure Control

Plan 53a relies on a pressure accumulator and regulating valves to maintain the barrier fluid pressure higher than the process fluid pressure. While this system is effective, it may experience pressure fluctuations and requires careful monitoring and adjustment.

In contrast, Plan 54 utilizes a bladder accumulator to provide a more stable and responsive pressure control system. The bladder accumulator maintains a constant pressure in the barrier fluid, automatically compensating for any changes in volume due to thermal expansion or minor leaks. This results in a more reliable and efficient pressure control system, reducing the risk of process fluid ingress into the seal chamber.

Complexity and Cost

Plan 54 is generally more complex and costly than Plan 53a due to the addition of the bladder accumulator and associated components. The bladder accumulator requires periodic maintenance and replacement, adding to the overall maintenance costs of the system. However, the increased reliability and performance of Plan 54 often justify the additional investment, particularly in critical applications or processes with high consequences of failure.

Reliability

The improved pressure control and stability provided by the bladder accumulator in Plan 54 make it a more reliable option compared to Plan 53a. The constant barrier fluid pressure maintained by the accumulator reduces the risk of process fluid ingress and minimizes the impact of thermal expansion and minor leaks.