Not understanding the difference between static and dynamic O-rings can lead to costly failures and unplanned downtime in machinery applications.

Incorrectly specifying static O-rings in dynamic applications or vice versa is a common mistake that compromises equipment performance and reliability.

In this article, we’ll clarify the key differences between static and dynamic O-rings, including factors like movement, pressure, heat generation, compression, wear, lubrication, misalignment, maintenance, gland design, materials, and applications. Understanding these critical distinctions will help you select the optimal sealing solution for your machinery needs.

What Is Static O-Ring

A static O-ring is a sealing element used in applications where there is no relative motion between the sealing surfaces. The O-ring is compressed between two stationary surfaces, creating a tight seal that prevents leakage of fluids or gases. Static O-rings are commonly found in hydraulic and pneumatic systems, valves, fittings, and other equipment where a reliable, leak-proof seal is essential.

What Is Dynamic O-Ring

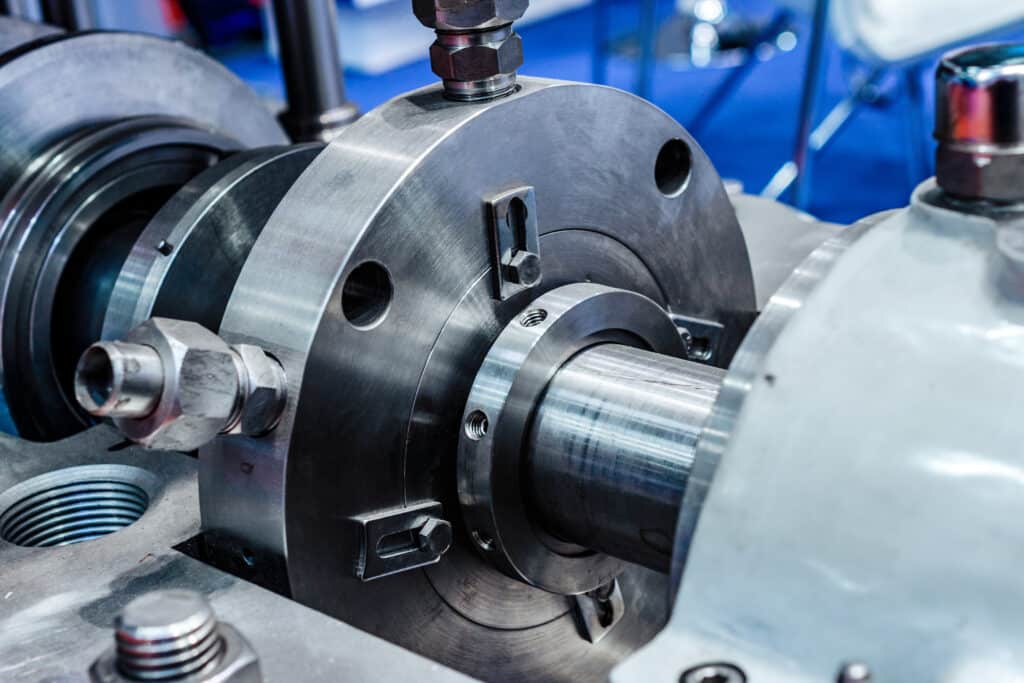

In contrast, a dynamic O-ring is designed for applications where there is relative motion between the sealing surfaces. The O-ring is typically installed in a groove or gland, allowing it to maintain contact with the moving surface while preventing leakage. Dynamic O-rings are used in a wide range of applications, such as hydraulic and pneumatic cylinders, rotary shafts, and reciprocating pumps.

The Difference Between Static and Dynamic O-Rings

Movement

Static O-rings are used in applications where there is no relative motion between the sealing surfaces. They are typically compressed between two stationary components to prevent fluid or gas leakage.

Dynamic O-rings are designed to seal components that have relative motion between them, such as rotating shafts or reciprocating pistons. The O-ring must maintain a seal while accommodating this movement.

Pressure

Static O-rings are often subjected to higher pressures compared to dynamic O-rings. In static applications, the O-ring is compressed between two surfaces, and the pressure acting on the seal remains relatively constant. This allows static O-rings to withstand significant pressure differentials without leakage.

Dynamic O-rings typically experience lower pressures due to the challenges associated with maintaining a seal during motion. The constant movement can lead to pressure fluctuations and potential leakage paths.

Heat Generation

Dynamic O-rings are more susceptible to heat generation compared to static O-rings. As the moving components slide against the O-ring, friction is generated, leading to increased temperatures at the sealing interface.

Static O-rings do not experience significant heat generation since there is no relative motion between the sealing surfaces.

Compression

Static o-rings rely on compression to create a tight seal between the mating surfaces. They are typically compressed by 15-30% of their original cross-section to achieve a leak-proof seal.

Dynamic o-rings require less compression, usually only 10-15%. Too much compression in a dynamic application increases friction and accelerates wear.

Wear

Dynamic O-rings are subject to greater wear compared to static O-rings due to the constant relative motion between the sealing surfaces. As the O-ring slides against the mating components, it experiences abrasion, which can lead to material loss and eventual seal failure.

Lubrication

Dynamic o-rings typically require lubrication to reduce friction and heat buildup as they slide against mating surfaces. The lubricant forms a film that prevents direct surface-to-surface contact.

Static o-rings generally do not need lubrication because they are not moving. In some cases, lubricant may actually be undesirable for static applications as it can attract contaminants.

Tolerance to Misalignment

Dynamic o-rings are more forgiving of small misalignments between mating parts compared to static o-rings. The lubricant film allows the dynamic o-ring to slide into place and maintain a seal despite slight offsets or eccentricities.

Static o-rings have little tolerance for misalignment. Even minor disparities between mating surfaces can result in leakage or seal failure for static o-rings because there is no lubricant film or movement to compensate for geometric imperfections.

Maintenance

Dynamic o-rings typically require more frequent maintenance and replacement than static o-rings. The constant motion against mating surfaces will wear the o-ring over time, even with proper lubrication. Regular inspection and periodic replacement is necessary.

Static o-rings may last the entire service life of the assembly without needing replacement, as long as they are not exposed to incompatible chemicals, extreme temperatures, or excessive compression set. Maintenance is less frequent for static o-rings.

Gland design

Gland design differs for static vs. dynamic o-rings. Dynamic glands must account for the motion of the o-ring, with consideration for travel limits, lubricant retention, thermal expansion, and wear. Lead-in chamfers are commonly used to avoid o-ring damage during installation into dynamic glands.

Static o-ring glands are comparatively simpler. They are designed to optimize squeeze and avoid excessive compression set. Static glands may include retaining mechanisms to prevent o-ring displacement during assembly.

Material

While some materials like nitrile rubber are suitable for both static and dynamic applications, dynamic o-rings often use specialized compounds like polyurethane, Viton®, or PTFE.

Applications

Static o-rings are used in countless applications to seal stationary connections, such as in valves, fittings, flanges, and threaded joints. Essentially any leak-prone connection between stationary parts can benefit from a static o-ring.

Dynamic o-rings enable leak-free operation in moving equipment like hydraulic and pneumatic cylinders, rotating shafts, reciprocating pumps, and valves. They are found in virtually every industry that uses moving machinery, including automotive, aerospace, medical devices, and industrial equipment.