Water hammer is a common issue in fluid systems, especially those with check valves. This article explores the causes, dangers, and prevention techniques for water hammer, focusing on the role of check valves in mitigating or exacerbating the problem.

What Is Water Hammer

Water hammer, also known as hydraulic shock, is a pressure surge or wave caused by the kinetic energy of a fluid in motion when it is forced to stop or change direction suddenly. This phenomenon can occur in fluid systems, including pipes and valves, and can lead to significant damage if left unchecked.

What Causes Water Hammer

- Sudden Changes in Fluid Velocity: Occurs due to rapid valve closure or pump shutdown. When a valve closes quickly or a pump stops abruptly, the fluid’s momentum is suddenly interrupted, causing a pressure wave to propagate through the system.

- High Fluid Velocities and Long Straight Pipe Runs: As the fluid moves at high speeds through extended, uninterrupted pipe sections, the potential for significant pressure surges increases when flow is suddenly stopped or redirected.

- Vertical Pipe Orientations with Upward Flow: In these cases, the fluid’s weight and the sudden change in direction can amplify the pressure surge, leading to more severe water hammer incidents.

- Improper Valve Selection and Placement: Valves that are undersized, misapplied, or located too close to pumps or other sources of flow disturbance can increase the likelihood and severity of water hammer events.

- Lack of Water Hammer Mitigation Devices: The absence of water hammer mitigation devices, such as surge tanks, air chambers, or water hammer arrestors, can contribute to the occurrence and severity of water hammer. These devices help absorb pressure surges and minimize the damaging effects of hydraulic shock.

How Check Valves Can Worsen Water Hammer

- Traditional swing check valves can worsen water hammer: These valves rely on reverse flow and gravity to close, which can lead to abrupt slamming and pressure surges. The valve disc travels a significant distance before sealing, allowing for a larger volume of fluid to reverse direction and create a more severe water hammer event.

- Other check valve designs are also prone to slamming: Tilting disc, double door, and stop-check valves can contribute to water hammer. These valves may close abruptly, causing sudden flow stoppages and pressure spikes.

- Fast-acting solenoid valves can contribute to water hammer: Valves that close very quickly can lead to sudden pressure changes and hydraulic shock waves in the system.

- Undersized or misapplied check valves exacerbate water hammer: When a check valve is too small for the flow rate or not suited for the specific application, it can cause excessive pressure drops, leading to more severe water hammer events.

Preventing Water Hammer with Proper Check Valve Selection

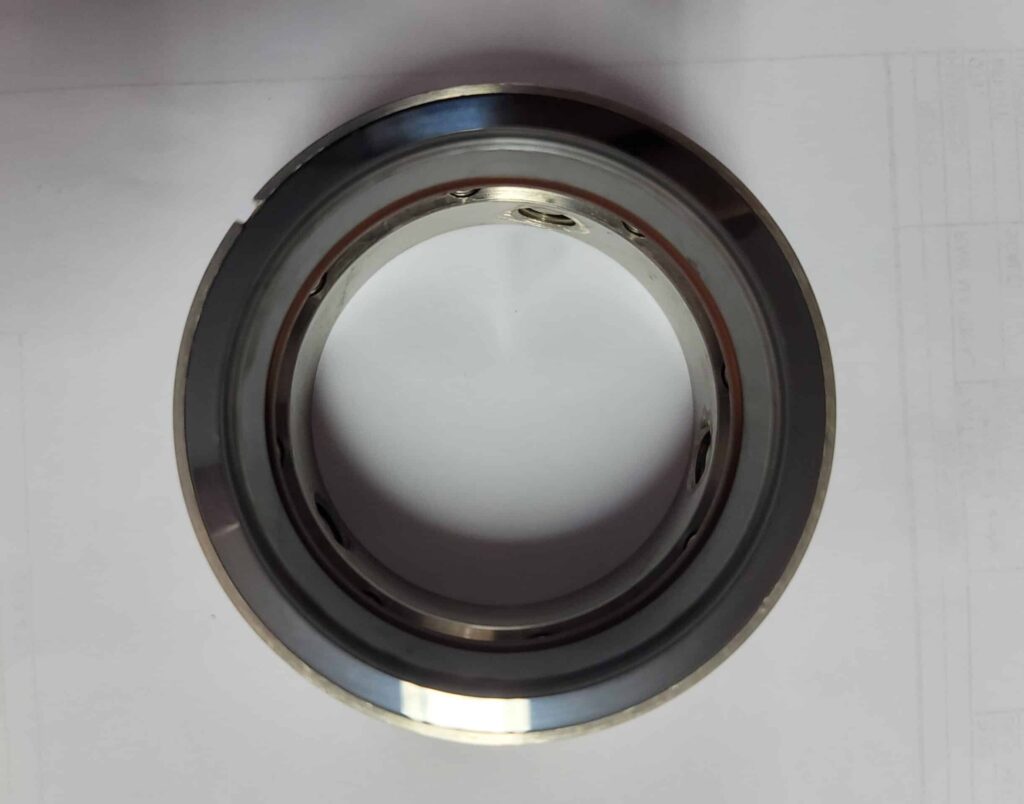

- Silent/Non-slam Check Valves: Feature spring-assisted closure mechanisms that close the valve before flow reversal occurs. These valves often have poppet-style discs with short travel distances, minimizing the volume of fluid that can reverse direction and cause water hammer. Non-slam check valves are effective in any orientation, making them versatile solutions for various applications.

- Nozzle Check Valves: Combine the benefits of non-slam design with low pressure drop. These valves have a streamlined flow path and a spring-loaded disc that closes quickly and smoothly, reducing the risk of water hammer while maintaining efficient system performance.

- Proper Valve Sizing: Essential for preventing water hammer. Valves should be selected based on factors such as flow rate, pipe size, and fluid properties to ensure optimal performance and minimize the risk of pressure surges.

- Valve Placement: Placing check valves away from pumps and other sources of flow disturbance can help reduce the risk of water hammer. By allowing sufficient distance between the valve and potential sources of sudden flow changes, the severity of pressure surges can be minimized.

Dangers of Ignoring Water Hammer

- Noise, vibration, and Cavitation Damage: Water hammer can cause significant noise and vibration in fluid systems, which can be both disruptive and indicative of underlying problems. Over time, the repeated stress from water hammer events can lead to cavitation damage, eroding pipes, valves, and other components.

- Ruptured Pipes, Supports, and Equipment: In severe cases, water hammer can cause pipes, supports, and equipment to rupture or fail. The sudden pressure surges can overwhelm the structural integrity of the system, leading to leaks, breaks, and potentially hazardous situations.

- Leaks at Joints and Fittings: Water hammer can cause leaks at joints and fittings, as the repeated stress from pressure surges weakens connections over time. These leaks can lead to fluid loss, reduced system efficiency, and potential safety hazards.

- Damaged System Components: Sensitive system components, such as gauges and meters, can be damaged by the intense vibrations and pressure spikes associated with water hammer. This damage can lead to inaccurate readings, impaired performance, and the need for costly repairs or replacements.

- Safety Hazards and Unplanned Downtime: Water hammer can create potential safety hazards, as the sudden failure of pipes or components can lead to fluid leaks, equipment damage, and even injuries to nearby personnel. Additionally, water hammer incidents often result in unplanned downtime, as repairs and replacements are needed to address the damage caused by pressure surges.

FAQs

Can Check Valves Cause a Water Hammer?

Yes, check valves can cause or contribute to water hammer if they are not selected or installed properly. Traditional swing check valves and other designs that are prone to sudden closure can lead to abrupt flow stoppages and pressure surges.

What Is the Best Check Valve for a Water Hammer?

The best check valve for preventing water hammer is a silent or non-slam check valve with a spring-assisted closure mechanism. These valves, such as poppet-style or nozzle check valves, close quickly and smoothly before flow reversal occurs, reducing the risk of sudden pressure changes and hydraulic shock waves.

Which Valve Causes Water Hammer?

Various valves can cause water hammer if they close too quickly or are not suited for the specific application. Traditional swing check valves, tilting disc valves, double door valves, stop-check valves, and fast-acting solenoid valves are among the types of valves that can contribute to water hammer if not selected or installed properly.

What Does Water Hammer Sound Like?

Water hammer often sounds like a loud banging, knocking, or hammering noise in pipes and valves. The intensity of the sound can vary depending on the severity of the pressure surge and the specific characteristics of the fluid system. In some cases, water hammer may also cause vibrations that can be felt throughout the piping network.

Conclusion

Water hammer is a serious issue in fluid systems, particularly those with check valves. By understanding the causes, dangers, and prevention techniques associated with water hammer, engineers and system designers can make informed decisions to mitigate this problem. Proper check valve selection, sizing, and placement are critical for minimizing the risk of water hammer and ensuring the longevity and reliability of fluid systems.