Which seal standard should you specify: ANSI or API? Across the industry, I see engineers agonize over this question as if the standard name itself determines seal life. It doesn’t. The real question is whether your operating conditions exceed specific thresholds that make standard ANSI seals insufficient.

This framing matters because seal-related repairs make up about 60 to 70% of all centrifugal pump maintenance work. Specifying the wrong standard costs you either way – over-specify and you pay for capability you don’t need; under-specify and you face premature failures. The actual thresholds, rather than industry labels, should drive your specification.

What ANSI and API Seal Standards Actually Specify

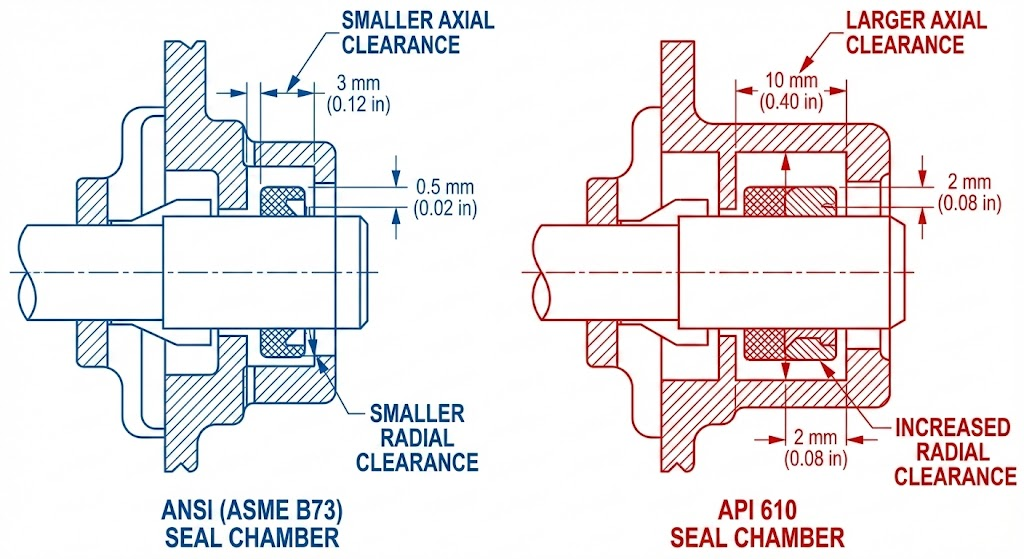

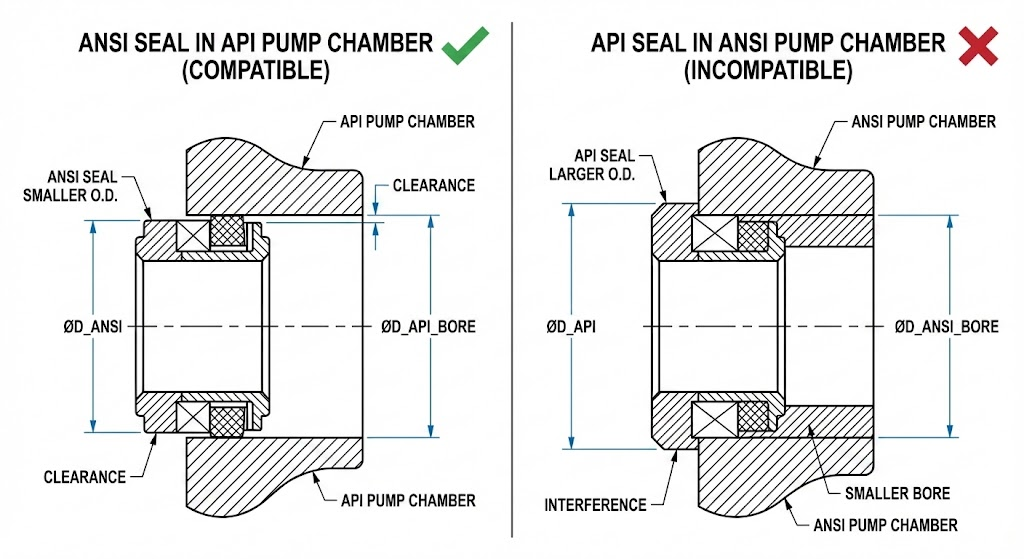

ANSI and API refer to different things entirely. ANSI (specifically ASME B73.1/B73.2) is a pump dimensional standard – it specifies the physical dimensions of pump components, including seal chambers. API 682 is a mechanical seal performance standard – it specifies design, testing, and documentation requirements for the seals themselves.

This distinction creates the first source of confusion. When someone asks for “ANSI seals,” they typically mean seals designed to fit ASME B73 seal chambers. When they ask for “API seals,” they mean seals built to API 682 specifications.

The performance envelopes differ widely:

| Standard | Pressure Rating | Temperature Rating |

|---|---|---|

| ASME B73 (ANSI) pumps | 300 psig | 300F |

| API 610 pumps | 750 psig | 500F |

These ratings explain why refineries and petrochemical plants gravitate toward API equipment. But the ratings alone don’t tell you which you need – your actual operating conditions do.

The Operating Condition Thresholds That Actually Matter

Instead of asking “ANSI or API?”, ask whether your operating conditions exceed these thresholds. Heinz P. Bloch, in the Pump User’s Handbook, provides specific criteria for when API-grade equipment becomes necessary:

- Head exceeds 350 ft (106.6 m)

- Temperature exceeds 300F (149C) for discharge flanges greater than 4 inches

- Temperature exceeds 350F (177C) for discharge flanges 4 inches or smaller

- Driver horsepower exceeds 100 hp (74 kW)

- Suction pressure exceeds 75 psig (516 kPag)

- Speed exceeds 3600 rpm

Exceed any of these, and you’re moving into territory where ANSI-rated equipment may become insufficient.

The hidden cost most buyers miss is the fluid factor. Unless you’re handling flammable, toxic, or explosion-prone liquids, many carefully selected ANSI pumps with appropriate seals work well. The fluid determines your safety margin requirements more than any other factor.

I’ve seen engineers confuse Category ratings with seal type limits, leading to specification errors. One engineer specified a Category 2 seal rated to 400C, not realizing the Type A seal arrangement within that category only allows 176C per API 682. The Category sets the operating envelope; the seal Type determines what you can actually achieve within it.

API 682 Categories: The Graduated Approach

API 682 doesn’t treat all applications equally. Its Category system provides a graduated approach that matches seal requirements to actual operating conditions:

Category 1 targets ASME B73.1/B73.2 (ANSI) seal chambers. Temperature range: -40F to 500F. Pressure limit: 315 PSI. This Category brings API reliability standards to ANSI pumps at lower cost than Category 2 or 3.

Category 2 targets API 610 pumps. Temperature range: -40F to 750F. Pressure limit: 615 PSI. Designed for refining, petrochemical, and chemical processing where conditions exceed Category 1 limits.

Category 3 covers the same temperature and pressure envelope as Category 2 but requires more rigorous testing and documentation. Specify this for critical services where unplanned downtime is unacceptable.

Seals designed for ASME B73 seal chambers will fit API 610 seal chambers, but the reverse is not true. API 610 seal chambers have more radial and axial clearance. If you’re upgrading from an ANSI pump to an API pump, your existing cartridge seals may still fit. But you cannot retrofit API seals into ANSI pumps without checking dimensions first.

Category 1 is the sweet spot for many chemical plants. You get API reliability standards – including the 25,000-hour (approximately 3-year) operational target – without paying for Category 2 or 3 capability you don’t need.

Making the Selection Decision

Two approaches dominate the industry, and both have merit.

The conservative approach follows a simple rule: “If it handles hydrocarbons, I go with API. No exceptions.” One reliability engineer in a refinery put it this way – the thorough design documentation and safety margins in API specifications justify the cost for any hydrocarbon service. This approach eliminates decision-making complexity and builds in safety margin.

The pragmatic approach uses threshold-based selection. If your operating conditions stay below Bloch’s thresholds and you’re not handling flammable or toxic fluids, standard ANSI equipment with appropriate seals serves well. This approach balances cost without sacrificing reliability.

Both approaches are valid. Your choice depends on risk tolerance, maintenance capability, and budget constraints.

Selection checklist:

- Do operating conditions exceed any Bloch threshold? (head, temp, hp, suction, speed)

- Are you handling flammable, toxic, or explosion-prone fluids?

- Does your industry or facility have regulatory requirements specifying API?

- What’s your acceptable MTBF and how critical is unplanned downtime?

If you answer “yes” to questions 1-3 or require maximum reliability from question 4, specify API 682 Category 2 or 3 seals. If none apply and you’re using ANSI pumps, Category 1 seals provide API reliability at lower cost.

The Verdict

The ANSI vs API debate often misses the point. What matters is whether your conditions exceed the thresholds where standard designs become insufficient.

For most chemical plant services below 300F, 300 psig, and 3600 rpm with non-hazardous fluids, Category 1 seals on ANSI pumps deliver the reliability you need. For refinery applications handling hydrocarbons at elevated temperatures and pressures, the conservative API approach makes sense.

Start with your operating conditions. Match them against the thresholds. Let the numbers, not the labels, drive your specification. When in doubt, consult your seal selection guide or engage a seal manufacturer with your specific operating data – they can recommend the right Category and configuration for your application.