When you’re writing a purchase order for mechanical seals, which standard should you reference – API 682 or ISO 21049? I’ve seen this question come up dozens of times from maintenance supervisors and procurement specialists who just want a clear answer. Both standards exist, both cover mechanical seals for centrifugal pumps, and both are technically valid. But here’s what matters: API 682 is the practical choice for most applications today, and I’ll explain exactly why.

What Are API 682 and ISO 21049?

API 682 and ISO 21049 are both mechanical seal standards for centrifugal and rotary pumps – but only one has kept pace with industry evolution.

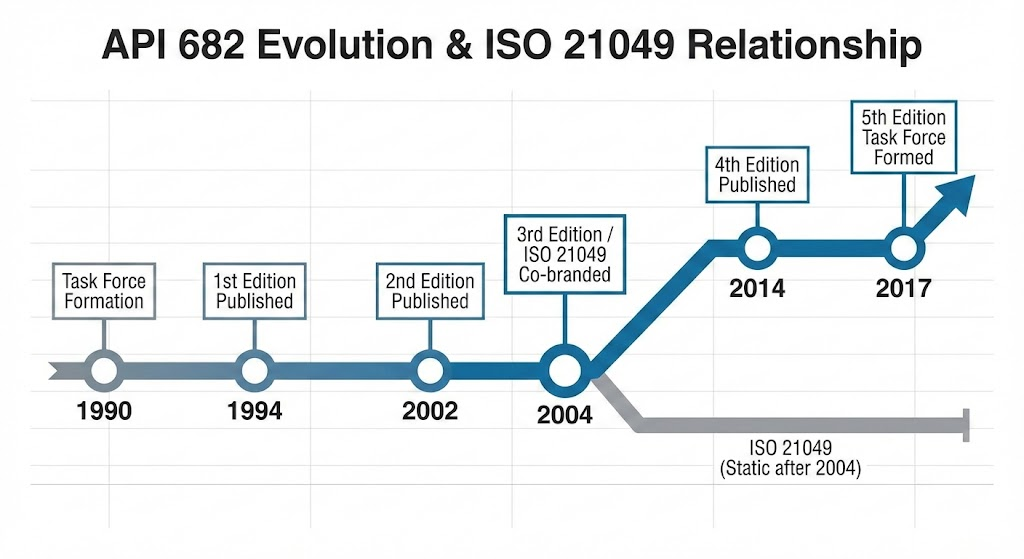

API 682 started in 1990 when V.R. Dodd of Chevron led a group of engineers frustrated that mechanical seal requirements were scattered across pump standards like API 610. They convinced the American Petroleum Institute to create a dedicated seal standard. A 14-member task force representing refineries, seal manufacturers, and pump makers developed what became API 682 First Edition, published in October 1994.

Since then, API mechanical seals have become the global benchmark. As EagleBurgmann puts it, API 682 has become “the standard that sets the global tone” for mechanical seal procurement – not just in American oil and gas, but worldwide in petrochemical and process industries.

ISO 21049, meanwhile, emerged from a 1998-2004 attempt to create a unified international standard. The idea was sound: take API 682 and make it an ISO document to give it broader international recognition. ISO made editorial changes – fixing typos, adding metric conversions – but the technical content remained essentially identical to API 682 2nd Edition. The result was ISO 21049:2004, published in February 2004.

The most common mistake I see is people treating these as truly different standards. At the 3rd Edition level (2004), they’re technically the same document. The real difference is what happened next.

Key Differences Between API 682 and ISO 21049

Technical Content: Identical Origins

When ISO 21049 was published in 2004, it was co-branded with API 682 3rd Edition. The API voted to accept the ISO document as an identical National Standard. For the content covered in that era – seal types, categories, seal arrangements, basic piping plans – there’s no technical difference between the two.

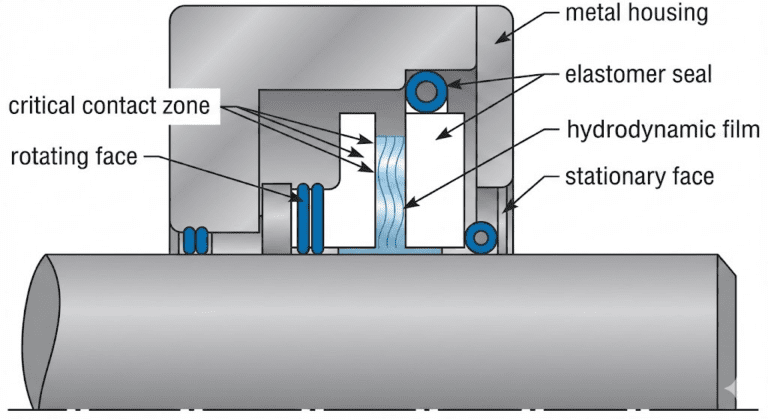

Both standards define:

- Types A, B, C: Pusher seals, metal bellows, and bellows with stationary O-rings

- Categories 1, 2, 3: Non-API pumps, API 610 pumps, and critical service API 610 pumps

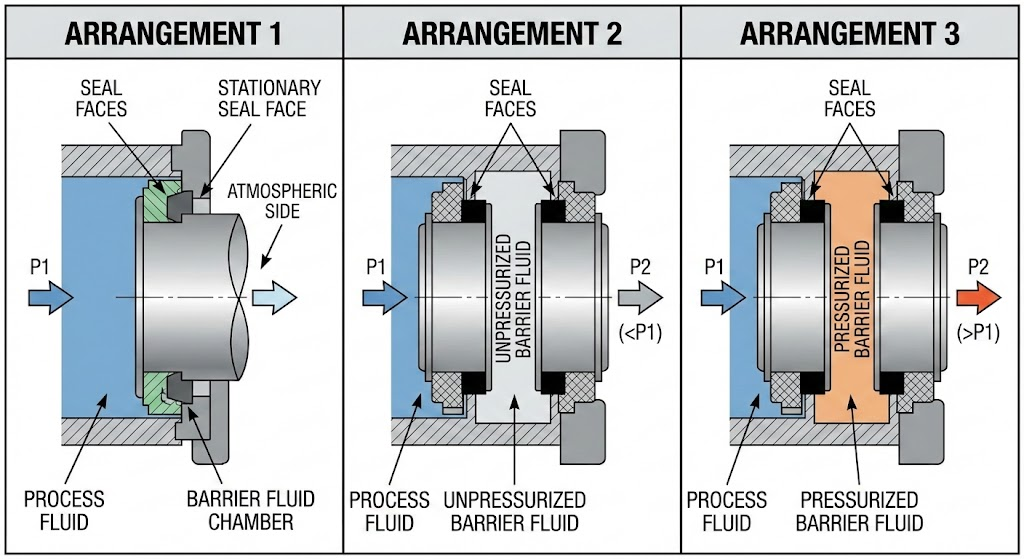

- Arrangements 1, 2, 3: Single seals, dual unpressurized, and dual pressurized

If someone hands you a seal specification written to either standard’s 2004 content, you’re getting the same requirements.

Update Status: Living vs Frozen

Here’s where the practical difference emerges. After the 3rd Edition, API and ISO ended their joint agreement. They went separate ways.

ISO 21049 was confirmed in 2021, meaning ISO reviewed it and decided it’s still valid. But “confirmed” doesn’t mean “updated.” The technical content remains unchanged from 2004. According to Seal FAQs, “The 2004 issue of ISO 21049 is the only issue and plans to update it are unknown.”

API 682, by contrast, continued evolving. The 4th Edition published in May 2014 after a 25-member task force spent six years incorporating two decades of field experience. And a 5th Edition task force formed in 2017, showing continued industry investment.

The real difference isn’t which document you reference – it’s which guidance you receive. ISO 21049 gives you 2004-era requirements. API 682 4th Edition gives you requirements informed by ten additional years of practical experience.

Why API 682 Has Evolved While ISO 21049 Stayed Frozen

API 682 keeps evolving because it’s what ScienceDirect describes as a “living standard” – “permanently maintained and updated by practical people, namely users and manufacturers.”

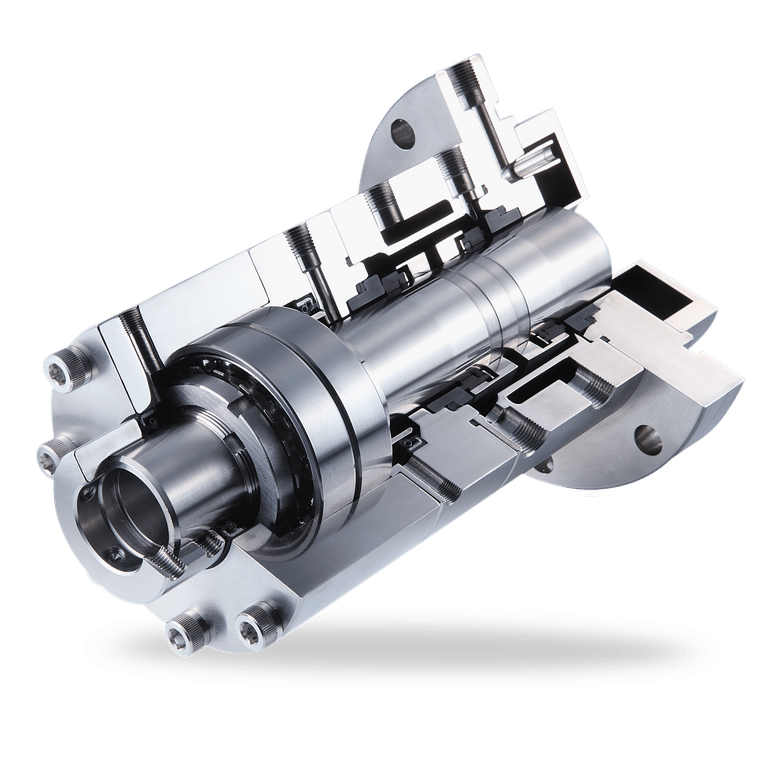

The 4th Edition wasn’t a cosmetic update. It expanded from approximately 200 pages to 260 pages. The tutorial section (Annex F) grew from 7 pages to 42 pages – because task force members recognized that engineers needed more guidance, not just specifications.

Specific improvements in the 4th Edition include:

- Six new piping plans: Plans 03, 55, 65A/B, and 66A/B address configurations that didn’t exist or weren’t standardized in 2004

- Minimum clearance specifications: First-time specification of minimum clearances for bushings

- Reservoir requirements: Minimum 28-day operating volume for Plans 52, 53A, 53B, and 53C

- Instrumentation updates: Transmitters with local indicators replacing simple switches

- Alternative selection method: GHS hazard code-based selection that considers toxicity, not just physical properties

These aren’t academic additions. They address real questions that came up in the field over 20 years of specifying and installing seals. When I’m specifying seals for a new installation, I want guidance on the latest piping plan options – and that guidance only exists in API 682.

ISO 21049 can’t offer this because the standard-maintenance infrastructure isn’t there. API has dedicated task forces with regular meetings, draft reviews, and balloting processes. The ISO mechanical seal standard simply hasn’t had that level of ongoing investment.

Which Standard Should You Specify?

For most applications, specify API 682 4th Edition. Here’s the decision framework I use:

Specify API 682 4th Edition when:

- You want the latest guidance on seal selection and piping plans

- Your application involves newer configurations (Plan 53B/C, for example)

- You need the expanded tutorials for training or reference

- Your supplier and end-user both accept API standards

- You’re working on oil and gas, petrochemical, or process industry projects

Specify ISO 21049 when:

- Your project contract specifically requires ISO-designated standards

- European regulatory requirements mandate ISO documentation

- Your customer’s purchasing system only accepts ISO standard numbers

- You’re retrofitting equipment originally specified to ISO 21049

The difference between API 610 and API 682 clarifies pump vs seal requirements, but within seal standards, the API vs ISO distinction is mostly administrative for 3rd Edition content.

Before you start writing specifications, make sure you understand what your project actually requires. Many international projects accept API 682 directly. Some European projects may require ISO designation for compliance documentation, but the seal itself can often be the same physical product.

When talking to seal suppliers, ask directly: “Can you supply to API 682 4th Edition?” Most reputable manufacturers can. If you specify ISO 21049, you’re effectively asking for a seal designed to 2004 requirements – which works, but you’re leaving newer guidance on the table.

The selection process itself has become more sophisticated in API 682 4th Edition, with flow charts spanning over 10 pages. If that complexity concerns you, work with your seal supplier to navigate it – but don’t avoid the 4th Edition just because it’s more thorough.

The Bottom Line

Both API 682 and ISO 21049 will get you a functional mechanical seal. The standards were identical in 2004, and seals built to that content perform well.

But if I’m specifying seals today, I want the latest practical guidance on piping plans, instrumentation, and selection procedures. That guidance exists in API 682 4th Edition – a living standard that reflects 30 years of field experience. ISO 21049 reflects where the industry was 20 years ago.

Specify API 682 4th Edition unless your project specifically requires ISO designation. When ISO is required, understand that you’re accepting 2004-era guidance, and work with your supplier to incorporate relevant 4th Edition improvements where your project allows flexibility.