Your seal is running hot. Does that mean you need a Plan 21 heat exchanger? In my experience troubleshooting seal systems across refineries and chemical plants, the answer is usually no. Plan 21 gets specified far more often than it should, and I’ve watched plants spend thousands on coolers that didn’t solve the actual problem.

Plan 11 handles 50-75% of all seal applications for good reason. It works. Plan 21 adds a heat exchanger to the same basic configuration, but that addition brings its own complications. Before you upgrade, let’s look at what actually drives this decision.

How Plan 11 and Plan 21 Work

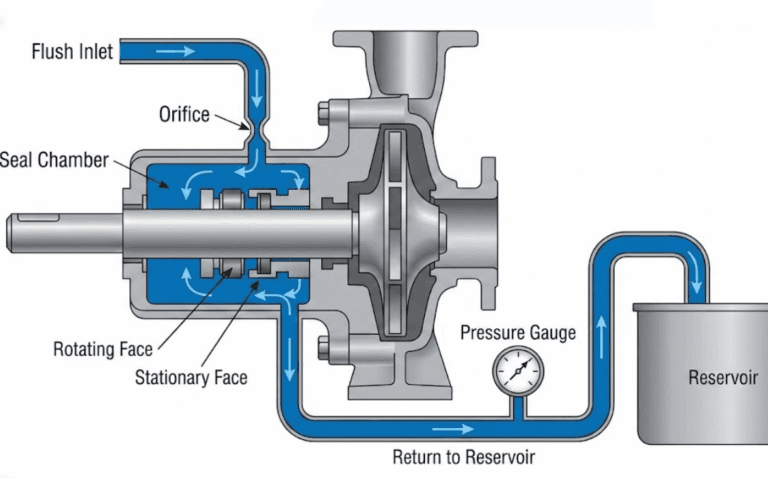

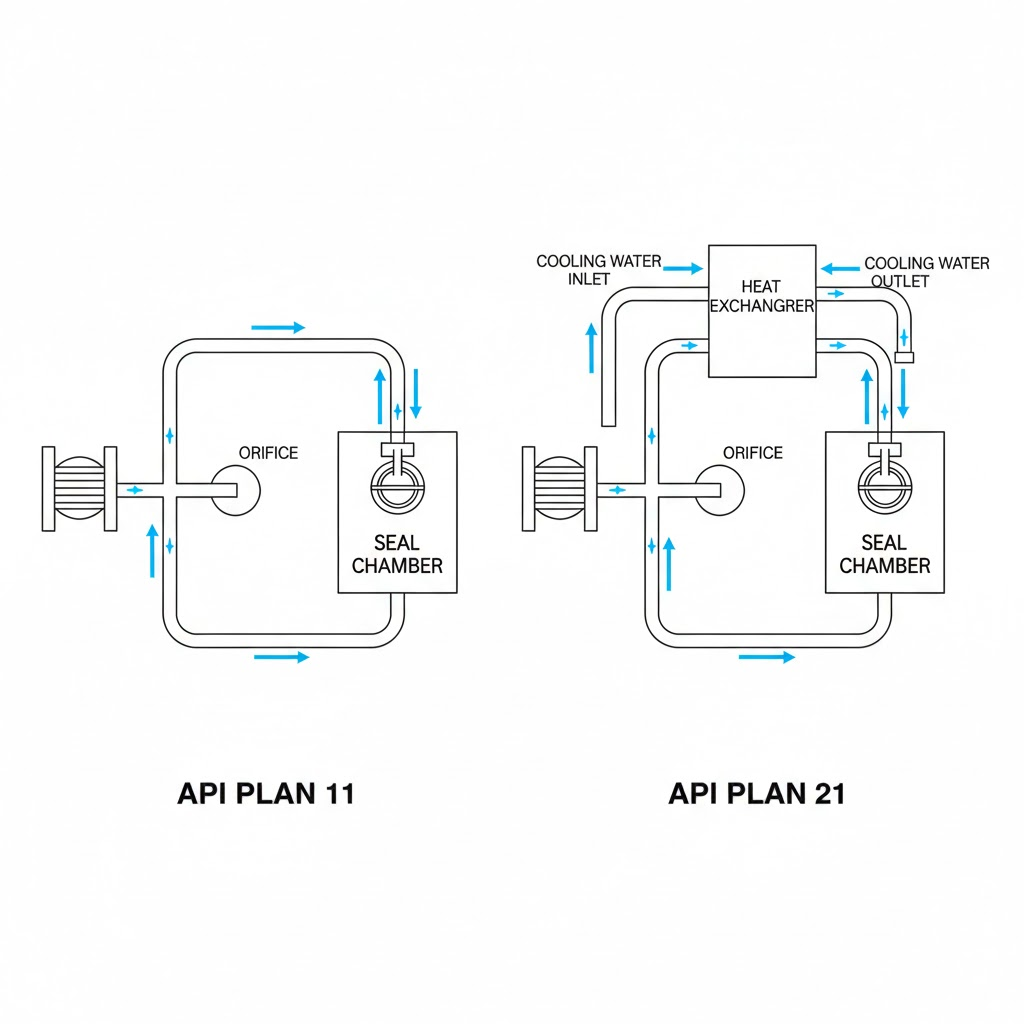

Plan 11 recirculates process fluid from the pump discharge through an orifice to the seal chamber. The fluid lubricates and cools the seal faces, then returns to the pump suction. Simple, reliable, and proven across decades of service.

Plan 21 takes the same flow path but routes it through a water-cooled heat exchanger first. The cooled fluid then enters the seal chamber at a lower temperature than the process.

| Factor | Plan 11 | Plan 21 |

|---|---|---|

| Components | Orifice, tubing | Orifice, tubing, heat exchanger |

| Cooling water required | No | Yes |

| Maintenance items | Orifice inspection | Orifice + heat exchanger cleaning |

| Relative cost | Lower | Several times higher |

The simplicity of Plan 11 is an advantage, not a limitation. Fewer components mean fewer failure points. Every heat exchanger I’ve seen eventually needs descaling, and some plants can’t keep up with the maintenance schedule.

The Real Selection Criteria

Most selection guides tell you to use Plan 21 above 150C (300F). That’s a rough guideline, not a rule. An experienced refinery engineer on Eng-Tips put it better: “The absolute temperature is not as important as knowing the vapor pressure margin.“

The real question is whether your process fluid will flash at the seal faces. API 682 specifies a vapor pressure margin of 50 psi minimum, or a 1:3 ratio between seal chamber pressure and fluid vapor pressure. If you maintain that margin, your seal faces stay wetted regardless of absolute temperature.

Temperature thresholds exist because they correlate with vapor pressure in many common fluids. But heavy oils at 300C might have more vapor pressure margin than light hydrocarbons at 100C. The threshold is a shortcut, not the criterion itself.

The most common mistake I see: specifying Plan 21 because the process temperature exceeds some arbitrary cutoff, without ever calculating the actual vapor pressure margin. You might be solving a problem that doesn’t exist.

Why Plan 21 Often Fails

Here’s what the selection guides don’t emphasize: Plan 21 is not a preferred plan by API or many experienced users.

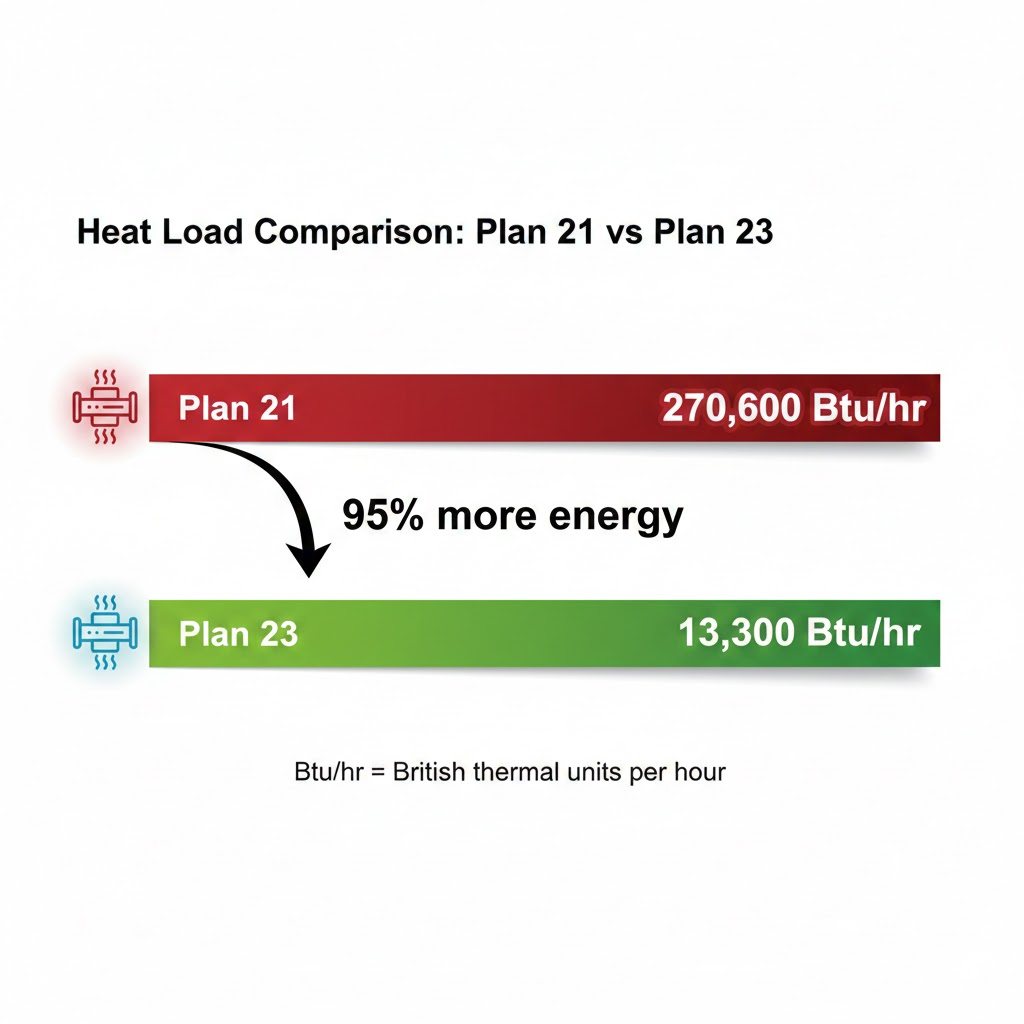

The fundamental problem is heat load. Cooling 3 gpm of water from 350F to 160F consumes 270,600 Btu/hr. That’s not a typo. Compare that to Plan 23, which achieves the same seal face temperature with only 13,300 Btu/hr. Plan 21 wastes 95% more energy because it tries to cool the full-temperature process fluid continuously.

The second problem is fouling. Process fluid enters the heat exchanger at maximum temperature. When hot fluid contacts the cooling surfaces, you get local boiling and mineral precipitation. This isn’t a maintenance failure. It’s inherent to how Plan 21 works. I’ve seen exchangers plug within months on hard water circuits.

Plan 21 has a narrow optimal window: roughly 150-230C. Below 150C, you probably don’t need cooling at all. Above 230C, Plan 23 is more efficient. That leaves a small range where Plan 21 makes sense, and even then, only if your process fluid is clean enough to avoid fouling the exchanger.

If you genuinely need cooling, skip Plan 21 and go straight to Plan 23 unless you have a specific reason not to.

Troubleshoot Plan 11 Before Upgrading

Before you order that heat exchanger, check whether your existing Plan 11 system is actually working correctly.

A diesel transfer pump at one facility kept running hot with Plan 11. The compact pump dimensions prevented a continuously rising flush line, requiring a manual vent valve. The solution wasn’t Plan 21. Engineers modified the piping from rigid pipe to flexible tubing, achieved the required slope, and eliminated the venting problem entirely. Plan 11 retained, API 682 compliance maintained, no cooler needed.

At a refinery, a pump operating at 500-700F was initially blamed on temperature. Investigation revealed the actual causes: low-flow operation causing shaft deflection, temperature cycling creating particulates, and high suction-specific speed. The solution focused on maintaining 70-110% BEP operation and consistent product temperature. That pump runs successfully with Plan 11 at temperatures well beyond Plan 21’s supposed range.

When asked about seal plans for 300C hot oil service, an experienced refinery engineer responded: “I would not normally consider a Plan 21 for service this hot.” His recommendations: Plan 11, 13, 54, or 32. One critical charge pump at his facility operates at 300C with excellent reliability using just Plan 02.

Before deciding on Plan 21, verify these items:

- Is your orifice clean? A clogged orifice starves the seal of flush flow.

- What’s the actual vapor pressure margin at operating conditions?

- Is the flush line properly sloped for venting?

- Are you running the pump near BEP?

- Is the process temperature consistent or cycling?

Making the Right Choice

Plan 11 handles most applications when properly implemented. If your seal runs hot, troubleshoot the existing system before adding complexity.

Plan 21 makes sense in a narrow window: 150-230C with clean process fluids and available cooling water. Outside that range, you’re either over-specifying or under-specifying.

If you actually need cooling, Plan 23 is almost always the better choice. It uses a pumping ring to circulate seal chamber fluid through a heat exchanger, reducing heat load by 95% compared to Plan 21.

The most expensive seal system is the one that doesn’t solve your actual problem. Verify what’s wrong before you specify the fix.