A plant manager opts for a cheaper unbalanced seal to save money upfront, only to watch it fail within months when pressure spikes. Then comes the emergency call, the production shutdown, and the expedited parts order. Suddenly, that “cheaper” seal cost ten times more.

The reality is simple: no single seal type works for every situation. Balanced seals and unbalanced seals are designed for different operating conditions, and choosing the right one can mean the difference between a seal that lasts five years and one that fails in five weeks.

What Is Balance in Mechanical Seal?

Understanding Balance Ratio

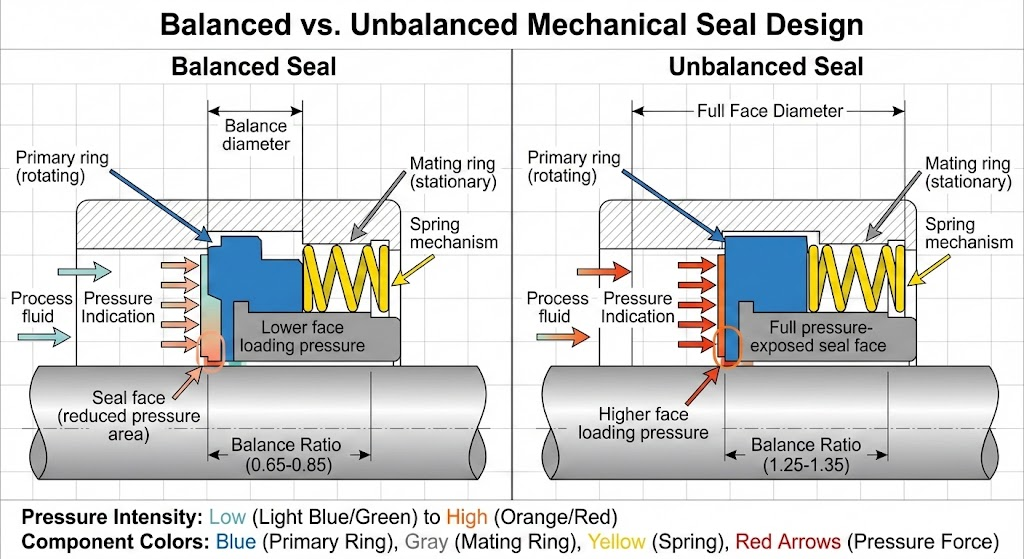

“Balance” in a mechanical seal refers to how the hydraulic forces are distributed across the seal faces. It’s measured as a ratio—a simple number that tells you how much of the pressurized fluid is pushing directly on the seal faces versus how much is being held back by the design.

The balance ratio is calculated by comparing two areas: the closing area (where pressure pushes the faces together) and the opening area (where pressure tries to push them apart). Here’s the formula:

Balance Ratio = Closing Area / Opening Area

A balanced seal has a ratio less than 1.0 (typically 0.60 to 0.90). This means the design intentionally reduces the area where pressure can push down on the seal faces. An unbalanced seal has a ratio greater than 1.0 (typically 1.10 to 1.60), meaning full pressure acts on the seal.

Why does this matter? Because balance ratio directly determines three critical performance factors: the maximum pressure the seal can handle, how much heat it generates, and how long it lasts before failing.

Key Differences Between Balanced and Unbalanced Seals

Design and Force Distribution

A balanced seal deliberately reduces the surface area exposed to pump pressure. Engineers do this by creating a shoulder or step in the seal design that shields part of the seal face from the pressurized fluid.

Think of it as a pressure management strategy. By reducing the area that pressure can act upon, you reduce the net force pushing the seal faces together. Less force means less friction, less friction means less heat, and less heat means longer seal life.

An unbalanced seal takes a different approach: it exposes the full pump pressure to the entire backside of the seal face. This creates maximum closing force and maximum face loading. The advantage? Simplicity and inherent stability. The disadvantage? That high loading generates significant heat and limits how much pressure the seal can tolerate.

Pressure Capability Comparison

Here’s where the differences become crystal clear: unbalanced seals simply cannot handle high pressure.

Unbalanced seals are typically limited to about 10 bar (approximately 150 psi) maximum operating pressure. If you push them beyond this, the hydraulic pressure overcomes the lubricating film between the seal faces. The film gets squeezed out, metal touches metal, and the seal fails within seconds. I’ve seen unbalanced seals that were supposed to handle 150 psi fail catastrophically when the system hit 160 psi—a 10 psi overage.

Balanced seals, by contrast, are engineered for 250 psi and above. Many industrial applications run them at 400, 600, or even higher pressures. The reduced face loading keeps that protective fluid film intact even when pressure spikes.

But here’s the practical reality: balanced seals can also operate just fine at lower pressures. If you’re running 50 psi, a balanced seal will work perfectly. An unbalanced seal will work too, but if there’s any chance of a pressure surge, the balanced seal gives you safety margin.

Heat Generation and Performance

Mechanical seals generate heat through two mechanisms: friction between the rotating faces and viscous shear of the fluid film between them.

Heat is the enemy of seal life. For every 18 degrees Fahrenheit (10 degrees Celsius) above a seal’s optimal temperature, the elastomeric components (the rubber seals that prevent leakage around the outside) degrade twice as fast. This is called the Arrhenius effect, and it’s brutal.

Unbalanced seals generate significantly more heat than balanced seals, because the higher face loading creates more friction. In a typical comparison, an unbalanced seal might generate 30 to 40% more heat than a balanced seal under the same pressure and speed conditions.

Balanced seals, with their lower face loading, maintain cooler operating temperatures. This means the rubber elastomers last longer, the seal faces wear slower, and the entire assembly survives longer in service.

For hot-oil transfer pumps operating at 300 degrees Fahrenheit or steam condensate systems at 250+ degrees Fahrenheit, using an unbalanced seal is asking for trouble. The combined heat from the process fluid and the seal friction will cook the elastomers, and you’ll face premature failure.

Stability Under Difficult Conditions

Now here’s where unbalanced seals actually shine: when things get messy.

Vibration, misalignment, and cavitation are the enemies of balanced seals. Because balanced seals have more complex geometry and finer tolerances, they’re more sensitive to shaft vibration and imperfect alignment. When the shaft wobbles or when vapor bubbles form and collapse in the fluid (cavitation), balanced seals struggle.

Unbalanced seals, with their simpler design and heavier face loading, actually perform better under these harsh conditions. The higher loading keeps everything stable, even when the shaft isn’t perfectly aligned or when the pump is cavitating.

This is why you’ll see unbalanced seals in equipment that operates under tough conditions: water pumps with aging infrastructure, HVAC systems with worn bearings, or slurry pumps where cavitation is constant.

It’s a trade-off. You lose pressure capability and gain stability.

When to Use Balanced Seals

Ideal Applications for Balanced Seals

Choose a balanced seal if you meet one or more of these criteria:

High-pressure systems: Anything running above 250 psi is a balanced seal application. This includes most industrial pumps in oil and gas, refining, and chemical processing.

High-speed equipment: Balanced seals reduce friction and heat, making them ideal for high-RPM applications. The lower face loading preserves the fluid film even at elevated speeds.

Low-lubricity or volatile fluids: Some fluids (like certain hydrocarbons, refrigerants, or cryogenic liquids) don’t lubricate well. They evaporate easily or provide minimal viscous protection. Balanced seals’ lower face loading helps maintain film integrity with these challenging fluids.

High-temperature service: Hot-oil systems, steam condensate, and heated process fluids all generate their own thermal challenges. A balanced seal’s lower friction keeps additional heat generation to a minimum.

Extended service-life requirements: If you need a seal that can run for years without maintenance, balanced seals are your choice. The reduced wear and heat generation give them superior longevity.

Energy efficiency: Industries focused on operational efficiency prefer balanced seals because they consume less power. Less friction means less energy lost to heat.

When to Use Unbalanced Seals

Ideal Applications for Unbalanced Seals

Choose an unbalanced seal if your situation matches these criteria:

Lower-pressure systems: Anything running below 150 psi is a candidate for unbalanced seals. Once you’re confident you won’t experience pressure spikes, unbalanced seals deliver reliable performance.

Cost-sensitive applications: Initial purchase price matters. Unbalanced seals are simpler to manufacture and therefore cheaper. If you’re specifying hundreds of seals for a municipal water system or a building’s HVAC equipment, the savings add up.

Water pumps and HVAC systems: These are classic unbalanced seal applications. The pressure is low (usually 5 to 100 psi), the system is stable, and the payoff is simplicity and low cost.

Equipment with vibration or misalignment: If you know your equipment operates with worn bearings, crooked mounting, or inherent vibration, an unbalanced seal’s stability advantage is compelling.

Cavitation-prone environments: If your pump is cavitating (vapor bubbles forming and collapsing), the simpler unbalanced design handles this better than a complex balanced seal.

How to Select the Right Seal for Your Application

Selecting the right seal type requires asking the right questions in sequence. Skip steps or guess, and you’ll make the wrong choice.

Step 1: Determine Operating Pressure

Start here. Operating pressure is the most critical factor.

Check your equipment’s design specifications. What’s the maximum continuous operating pressure? What’s the relief valve setting? Are there any pressure spikes or transient conditions?

If your continuous operating pressure is above 250 psi, or if there’s any chance of pressure reaching 250 psi, you need a balanced seal. Full stop.

If your continuous pressure is below 150 psi and you’re confident it won’t spike beyond 150 psi, an unbalanced seal is an option worth considering.

The gray zone between 150 and 250 psi is where careful judgment comes in. You might use an unbalanced seal if the system is very stable and highly monitored, but I’d generally recommend balanced seals for safety and longevity.

Step 2: Assess Temperature and Fluid Conditions

Temperature is the second filter.

What’s the normal operating temperature? What’s the maximum temperature the system might reach? Is the fluid inherently hot (hot oil, steam), or is it ambient temperature?

For high-temperature applications (above 200 degrees Fahrenheit), lean toward balanced seals. The reduced friction keeps seal temperatures down and extends elastomer life.

Also evaluate the fluid’s lubricity. Does it lubricate well, or is it thin and slippery? Low-lubricity fluids need balanced seals because the lower face loading helps maintain film integrity with fluids that don’t provide much natural protection.

Check for volatile or flashing fluids. If the fluid tends to vaporize at certain pressures or temperatures, a balanced seal’s superior film maintenance is advantageous.

Step 3: Evaluate Installation Environment

Real-world equipment conditions matter.

Is the shaft well-aligned, or does the equipment have years of wear and vibration? Are bearings in good condition, or is there noticeable runout? Can you ensure proper alignment during installation?

If you suspect vibration or misalignment issues, an unbalanced seal’s stability advantage becomes compelling. The simpler design tolerates imperfection better.

Assess cavitation likelihood. Does the pump inlet cavitate? Is there vapor formation in the system? If cavitation is present or suspected, an unbalanced seal typically outperforms a balanced seal.

Step 4: Balance Cost vs. Performance Needs

Compare lifecycle cost, not just purchase price.

An unbalanced seal might cost $200 while a balanced seal costs $500. But if the unbalanced seal fails every 18 months while the balanced seal runs for 5 years, which is really cheaper?

Calculate it: Unbalanced seal at $200 failing four times in 6 years = $800 plus four seal replacements and maintenance labor. Balanced seal at $500 lasting 6 years = $500 total cost. The balanced seal is $300 cheaper, and you’ve avoided four maintenance events.

Add in the cost of production downtime (often $5,000 to $50,000 per hour for industrial operations), expedited shipping on emergency parts, and overtime labor, and the decision becomes obvious for high-reliability applications.

For low-stakes equipment—a backup pump, a utility circulation pump, or an auxiliary system—the cost difference matters more. Use an unbalanced seal if you’re comfortable with shorter maintenance intervals.