When a mechanical seal begins to leak, it may be tempting to simply tighten the seal to stop the leakage. However, tightening a mechanical seal can be risky and may lead to further problems if not done properly.

The Risks of Tightening a Leaking Mechanical Seal

Distortion of Seal Components and Increased Leakage

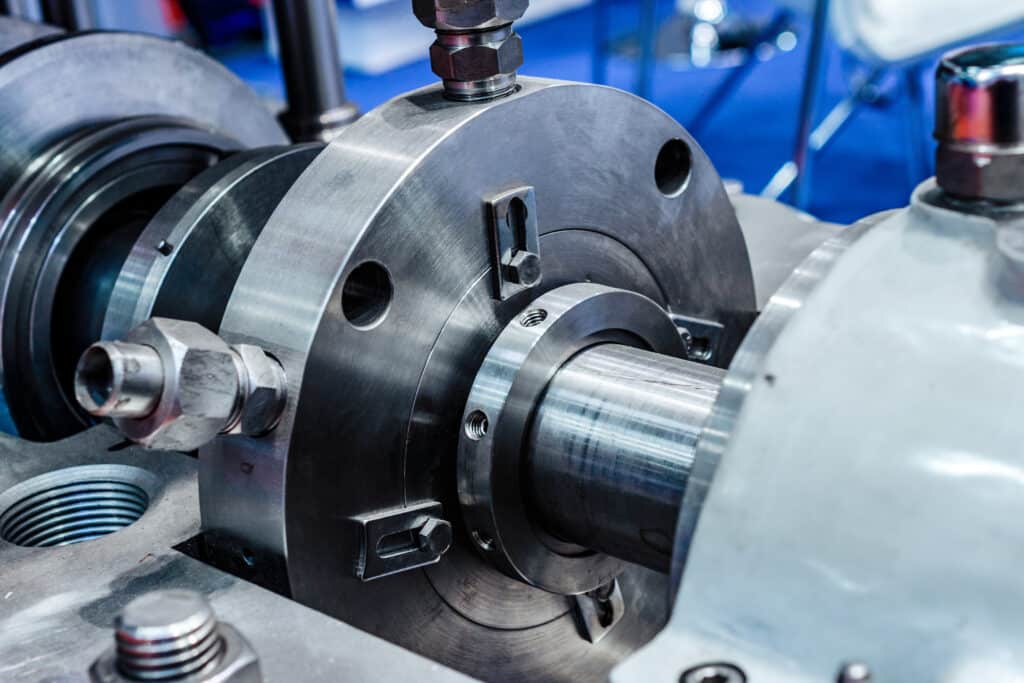

Overtightening a mechanical seal can cause distortion of the seal faces, O-rings, and other components. This distortion can lead to increased leakage as the sealing surfaces become misaligned or damaged. In some cases, overtightening may even cause the seal faces to crack or break, resulting in complete seal failure.

Excessive Face Contact Pressure, Heat Generation, And Accelerated Wear

When a mechanical seal is tightened beyond its designed limits, the contact pressure between the seal faces increases. This excessive pressure can generate heat due to increased friction, leading to accelerated wear of the seal faces. As the faces wear down, the seal’s performance deteriorates, and leakage may worsen over time.

Mechanical Shock and Damage to Seal Internals

Tightening a mechanical seal abruptly or with excessive force can create mechanical shock within the seal assembly. This shock can damage internal components such as springs, bellows, and drive mechanisms. Damaged internals may cause the seal to lose its ability to maintain proper face contact pressure and alignment, resulting in leakage and premature failure.

Compression of Springs and Improper Seal Balance

Mechanical seals rely on precisely engineered springs to maintain the correct balance between the seal faces. Overtightening the seal can compress these springs beyond their designed limits, altering the seal balance. An improperly balanced seal may experience increased face contact pressure on one side while losing contact on the other, leading to uneven wear and leakage.

When to Tighten Mechanical Seal

Tightening a mechanical seal should only be considered as a temporary measure in specific situations:

- During initial installation, if the seal is leaking slightly due to incorrect installation or insufficient compression of the seal faces, careful tightening may help establish proper sealing.

- If the seal has been in service for an extended period and has experienced normal wear, minimal tightening may compensate for face wear and restore sealing performance temporarily.

- In emergency situations where a small leak must be stopped quickly to prevent damage or loss of process fluid, tightening the seal slightly may be necessary until a proper repair can be scheduled.

How to Tighten Mechanical Seal

If you’ve determined that tightening your mechanical seal is necessary, follow these step-by-step instructions to ensure proper adjustment:

- Ensure the pump is switched off and isolated from any power source to prevent accidental startup during the tightening process.

- Allow the pump and seal area to cool down to a safe temperature before proceeding with any adjustments.

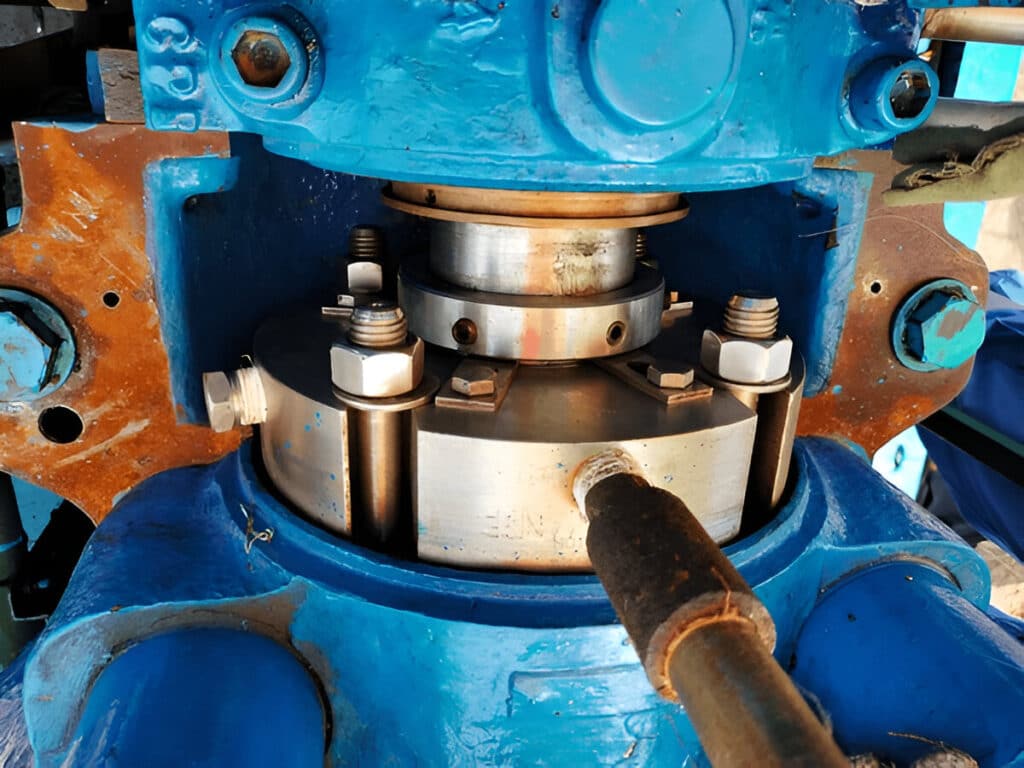

- Locate the adjustment screws or bolts on the seal gland. These are typically found on the sides or top of the gland, depending on the specific seal design.

- Using the appropriate tools (e.g., hex wrench or screwdriver), slowly and evenly tighten each adjustment screw or bolt by a small increment, such as a quarter turn. It’s essential to tighten each screw or bolt by the same amount to maintain even compression on the seal faces.

- After each incremental adjustment, rotate the pump shaft by hand to ensure it turns freely without binding or excessive resistance. If you feel any resistance or hear unusual noises, stop tightening immediately and consult the seal manufacturer’s guidelines or a professional.

- Monitor the seal for leakage after each adjustment. If the leak persists, continue tightening the adjustment screws or bolts incrementally until the leak stops or the maximum recommended compression is reached.

- Once the leak has stopped, continue to monitor the seal closely for any signs of overheating, unusual noises, or increased power consumption, as these may indicate excessive compression or damage to the seal components.

Remember, tightening a mechanical seal should only be done as a temporary measure to stop leakage until a proper repair or replacement can be scheduled. Over-tightening the seal can lead to increased wear, heat generation, and ultimately, premature seal failure.