Why does the same sulfuric acid solution destroy one mechanical seal in weeks while another runs for years? The answer rarely appears on compatibility charts: material chemistry, operating temperature, and concentration interact in ways that simple A/B/C ratings cannot capture.

I have spent 15 years diagnosing seal failures, and the pattern is consistent. Engineers select materials based on compatibility tables, then wonder why the seal failed. The tables are not wrong, but they assume room temperature, pure chemicals, and ideal conditions. Real process environments are none of these.

This guide covers the three component groups that determine chemical resistance: seal face materials, secondary seals (elastomers), and metal hardware. More importantly, it explains the attack mechanisms so you can make informed decisions when your application falls outside the standard charts.

How Chemicals Attack Seal Materials

Chemical attack on seal components follows predictable patterns once you understand the underlying mechanisms. Two principles explain most compatibility failures.

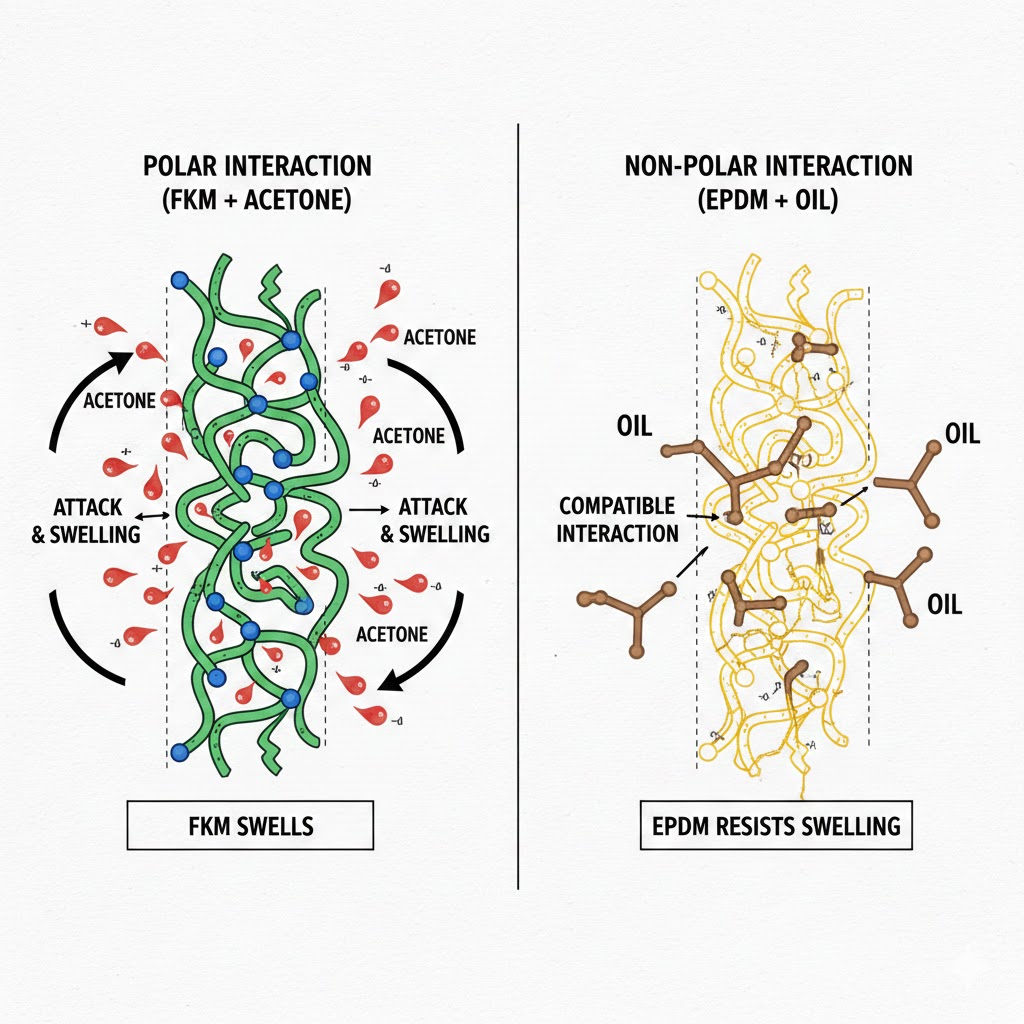

The “Like Dissolves Like” Principle

Polar chemicals dissolve polar materials. Non-polar chemicals dissolve non-polar materials. This single rule explains why FKM and EPDM have opposite compatibility profiles.

FKM (Viton) contains polar fluorine bonds that resist non-polar hydrocarbons like gasoline, diesel, and mineral oils. Those same fluorine bonds make FKM vulnerable to polar solvents like acetone, MEK, and ethyl acetate.

EPDM is a non-polar hydrocarbon rubber. It dissolves readily in petroleum products but resists polar chemicals including water, steam, and ketones.

This is not a quality issue or manufacturing defect. When you specify the wrong elastomer, you are placing a material into its chemical enemy. Failure is rapid, not gradual wear.

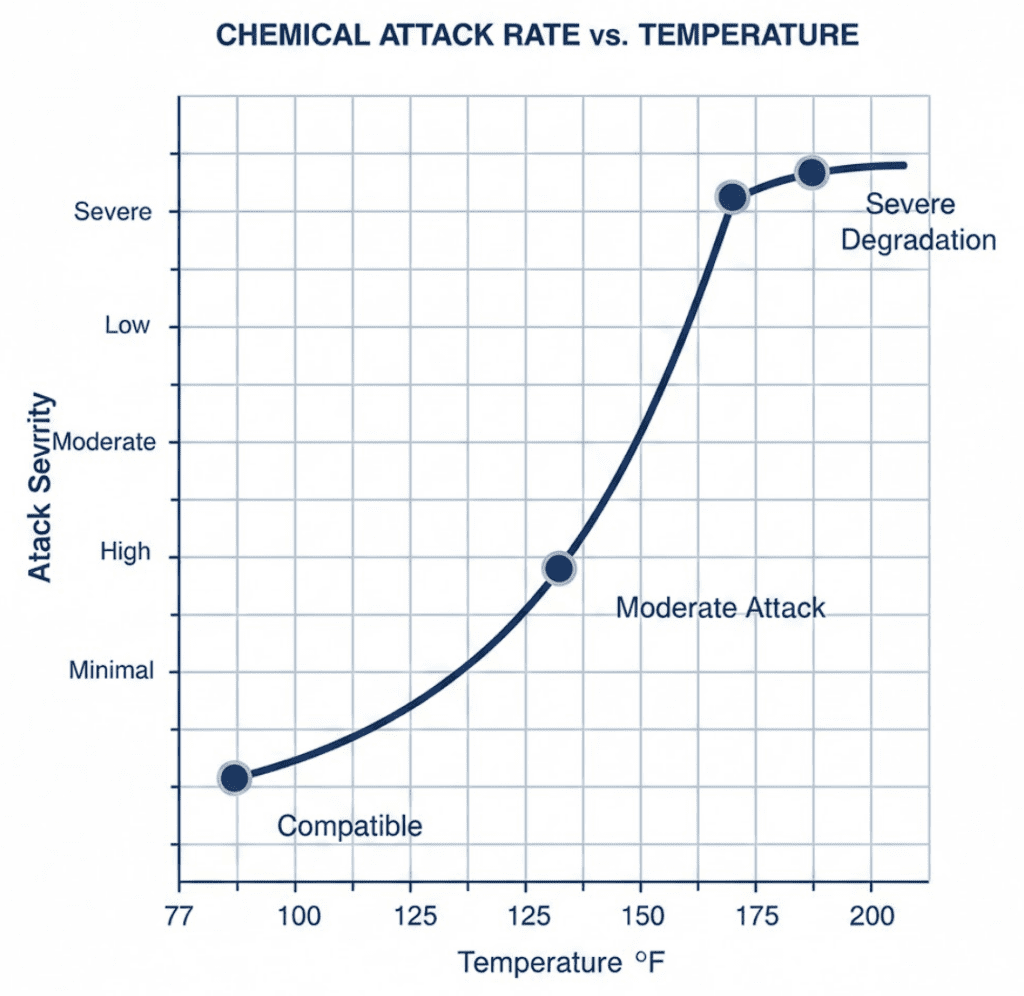

Temperature Acceleration Effect

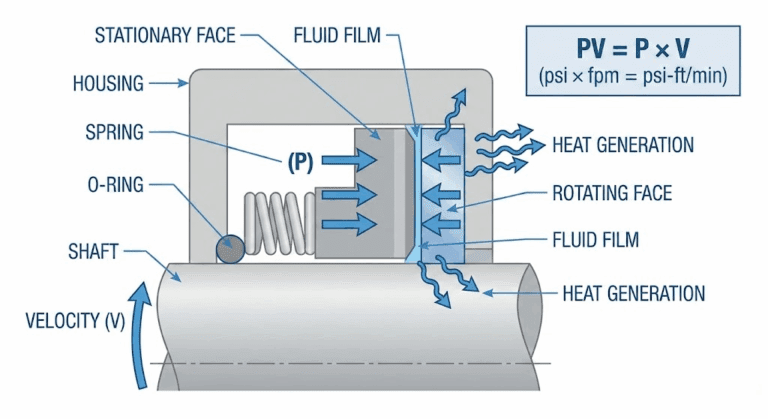

Chemical activity roughly doubles for every 20 degree Fahrenheit rise in temperature. A seal material that works at room temperature may fail at operating temperature.

The actual seal face temperature often exceeds bulk fluid temperature. Frictional heat at the interface can add 50-100 degrees Fahrenheit above process temperature. When consulting compatibility charts, use the estimated face temperature, not the process temperature.

A practical example: FKM rated compatible with dilute sulfuric acid at 77F may show moderate attack at 150F and severe degradation at 200F. The same chemical, the same elastomer, sharply different outcomes based solely on temperature.

Face Material Chemical Resistance

Face materials generally offer broader chemical resistance than elastomers, but each has specific limitations that compatibility charts often understate.

Carbon Graphite Limitations

Carbon graphite resists most chemicals due to its inherent inertness. The 80% carbon, 20% graphite mixture remains stable across a wide pH range and resists most acids and alkalis.

The critical exception: oxidizing agents. When exposed to oxidizers, carbon combines with oxygen to form carbon monoxide or carbon dioxide, eroding the seal face.

A practical identification rule: avoid chemicals whose names contain “peroxide,” “chlorate,” “perchlorate,” “nitrate,” or “permanganate.” The halogen group (chlorine, fluorine, bromine, iodine) also attacks carbon graphite.

Carbon grade affects temperature limits:

- Resin-filled carbon (#9 grade): maximum 500F (260C)

- Antimony-filled carbon (#10 grade): maximum 700F (370C)

For oxidizing services above moderate concentration, switch to silicon carbide faces.

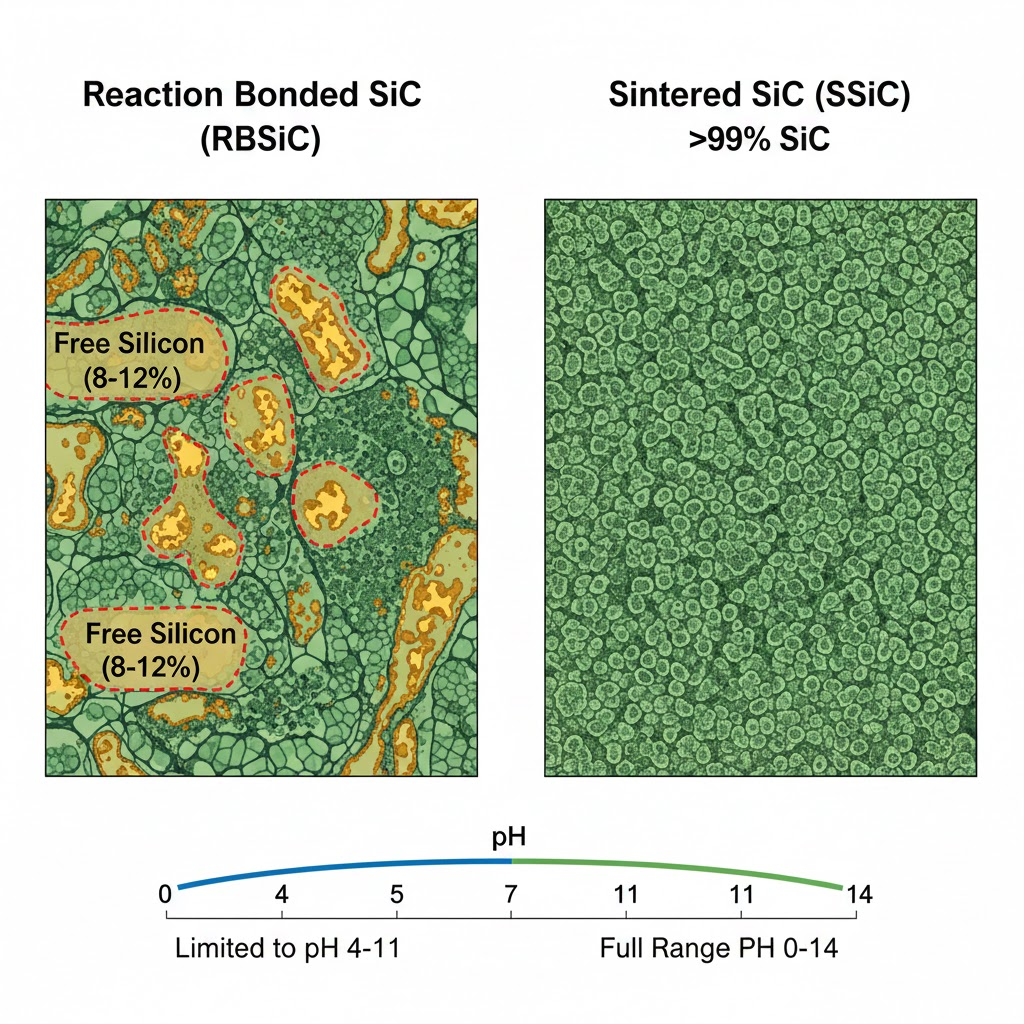

Silicon Carbide: Reaction Bonded vs Sintered

Silicon carbide offers superior chemical resistance to carbon, but the manufacturing method matters.

Reaction bonded silicon carbide (RBSiC) contains 85-90% SiC with 8-12% free silicon metal. That free silicon creates a pH limitation. As a rule, reaction bonded SiC should not be used in applications with pH below 4 or above 11. Strong acids and caustics attack the free silicon, leaving a porous, weakened structure.

Sintered silicon carbide (SSiC) contains more than 99% SiC with no free silicon. It handles the full pH range and offers superior acid/alkali resistance. Maximum temperature: 800F (427C).

For moderate pH applications (4-11), either grade performs well and RBSiC costs less. For strong acids or caustics, specify sintered SiC regardless of cost difference.

Elastomer Selection by Chemical Group

Elastomers fail more frequently than face materials in chemical service. The secondary seals see the same chemical exposure without the benefit of hard ceramic construction.

FKM (Viton): Strengths and Critical Weaknesses

FKM is the default “chemical resistant” elastomer. It handles hydrocarbons, petroleum products, mineral acids, and chlorinated solvents. Temperature range: -20C to +200C.

Critical weaknesses that compatibility charts often minimize:

Ketones and esters. Acetone, MEK, ethyl acetate cause rapid swelling and degradation. If your process contains these solvents, FKM is not suitable regardless of concentration.

Hot water and steam. FKM fails in steam and hot water above 150F due to hydrolysis. The OH radicals cause chain scission, breaking the polymer into shorter segments. The elastomer loses elasticity, develops cracks, and eventually fails. This is fundamental chemistry, not a quality defect. For hot water or steam service, specify EPDM.

Amines and ammonia. Strong bases attack FKM. For ammonia refrigeration or amine services, specify EPDM or FFKM.

EPDM: The Polar Opposite

EPDM excels where FKM fails: hot water, steam, ketones, dilute acids, and alkalis. Temperature range: up to 150C (302F).

EPDM fails in petroleum products, mineral oils, and hydrocarbon solvents. A single exposure to gasoline or diesel destroys EPDM rapidly.

For water treatment, steam systems, and ketone solvents, EPDM is the correct baseline choice.

When to Specify FFKM

FFKM (Kalrez, Chemraz) offers near-universal chemical resistance and handles 1,800+ chemicals. Temperature capability reaches 316C (600F).

FFKM is not automatically the right choice. I have seen FFKM fail rapidly in chlorine service despite premium ratings. Even perfluoroelastomers have specific grade requirements for specific chemicals.

FFKM costs 10-20 times more than FKM. Specify it when no other elastomer works, not as a default premium upgrade.

Practical limitations: FFKM has poor low-temperature flexibility with glass transition around -20C. For cryogenic or cold startup applications, verify the specific grade’s low-temperature rating.

Interpreting Compatibility Ratings

Compatibility charts use various rating systems: A/B/C/D, 1-4, or percentage swell. Here is how to interpret the numbers behind the ratings.

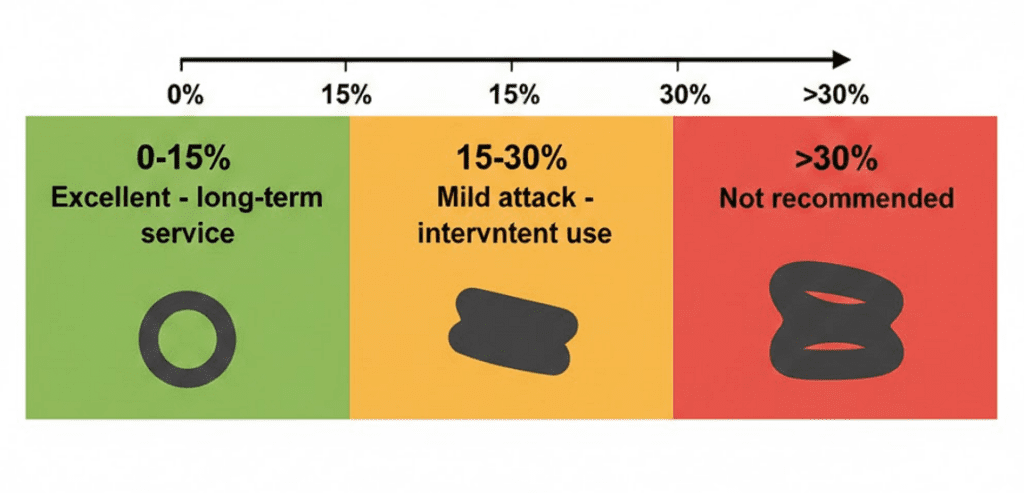

Volume swell percentage is the most meaningful metric:

- Less than 15% swell: Excellent compatibility, suitable for long-term service

- 15-30% swell: Mild attack, acceptable for intermittent exposure or short service life

- Greater than 30% swell: Moderate to severe attack, not recommended

When ratings disagree between sources, the conservative rating is usually tested at higher temperature or longer exposure. Use the more restrictive rating.

For mixed media (multiple chemicals in process fluid), test compatibility against each component individually. The weakest compatibility determines your material selection. When in doubt, request immersion testing from your seal supplier.

Conclusion

Chemical compatibility depends on three factors beyond the chemical name: temperature at the seal face, concentration, and exposure duration.

Start with attack mechanisms. Polar chemicals attack polar elastomers. Oxidizers attack carbon. Free silicon in reaction bonded SiC limits pH range. These principles explain most failures better than memorizing compatibility tables.

For face materials: carbon graphite handles most services except oxidizers. Silicon carbide handles aggressive chemicals, with sintered SiC required outside pH 4-11.

For elastomers: FKM resists hydrocarbons but fails in hot water and ketones. EPDM resists water and polar solvents but fails in petroleum. FFKM is the solution when nothing else works, not a default upgrade.

When your application involves mixed chemicals, temperatures above 150F, or concentrations outside typical ranges, consult your seal application engineer before specifying materials. The API 682 standard specifies material grades for good reason: they are field-validated performance guidelines, not laboratory theory.