Bulkhead shaft seals are essential components in various industries, ensuring the proper functioning and longevity of machinery. This article will explore the different types of bulkhead shaft seals, their unique features, and their applications. By understanding the characteristics of each seal type, readers can make informed decisions when selecting the most suitable seal for their specific needs.

Mechanical Seals

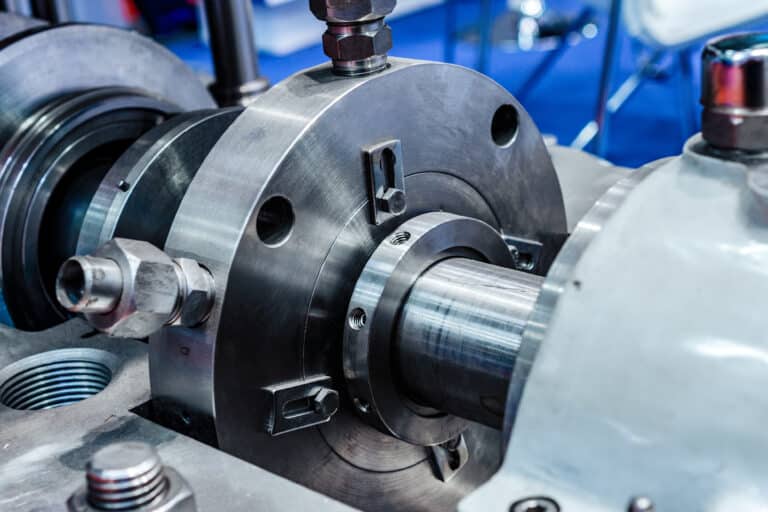

Mechanical seals are a popular choice for bulkhead shaft sealing applications. These seals consist of two main components: a stationary seal ring and a rotating seal ring. The stationary ring is typically mounted on the bulkhead, while the rotating ring is attached to the shaft. The two rings are precisely machined to create a tight seal when they come into contact with each other.

One of the key advantages of mechanical seals is their ability to handle high pressures and temperatures. Mechanical seals also offer excellent chemical resistance, making them suitable for use in harsh environments.

To ensure optimal performance, mechanical seals require proper lubrication and cooling. This is often achieved through the use of a barrier fluid, such as oil or water, which is circulated between the seal faces.

Lip Seals

Lip seals, also known as radial shaft seals, are another common type of bulkhead shaft seal. These seals feature a flexible lip that is typically made from elastomeric materials such as rubber or polyurethane. The lip is designed to maintain constant contact with the rotating shaft, creating a barrier that prevents fluid leakage.

Lip seals are known for their simplicity and cost-effectiveness. They are easy to install and require minimal maintenance compared to other seal types. However, lip seals have limitations in terms of pressure and temperature capabilities. They are best suited for low to medium pressure applications and moderate temperature ranges.

One important consideration when using lip seals is the surface finish of the shaft. A smooth, polished shaft surface is essential for proper sealing and to minimize wear on the lip material. Additionally, lip seals may require a secondary seal, such as an O-ring, to provide a more secure sealing solution.

Pressure-Activated Composite Seals

Pressure-activated composite seals are a specialized type of bulkhead shaft seal that offer superior sealing performance in demanding applications. These seals consist of a composite material, such as carbon fiber or polytetrafluoroethylene (PTFE), combined with an elastomeric energizer.

The unique design of pressure-activated composite seals allows them to adapt to varying pressure conditions. As the system pressure increases, the elastomeric energizer expands, pushing the composite material against the shaft and creating a tighter seal. This dynamic sealing action ensures reliable performance even in fluctuating pressure environments.

Pressure-activated composite seals are highly resistant to wear, corrosion, and chemical attack. They can handle high temperatures and pressures, making them ideal for use in extreme operating conditions.

Non-Contacting, Hydro-Activated Seals

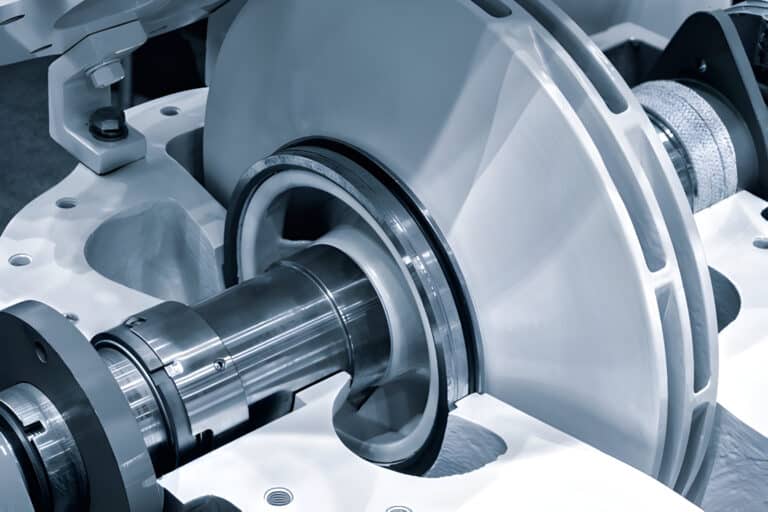

Non-contacting, hydro-activated seals represent an advanced sealing solution for bulkhead shaft applications. These seals operate without direct contact between the seal faces, eliminating friction and wear. Instead, they rely on a thin film of fluid, typically oil or water, to create a sealing effect.

The key component of a non-contacting, hydro-activated seal is a specially designed groove pattern on the seal face. As the shaft rotates, the groove pattern generates a hydrodynamic force that lifts the seal face away from the shaft, creating a small gap. The fluid film in this gap provides the sealing action, preventing leakage while minimizing heat generation and power consumption.

Non-contacting, hydro-activated seals offer several advantages over traditional sealing methods. They exhibit minimal wear, resulting in longer seal life and reduced maintenance requirements. The absence of direct contact also eliminates the need for lubrication, simplifying the sealing system.

However, non-contacting, hydro-activated seals have specific operating requirements. They rely on a continuous supply of clean, debris-free fluid to maintain the sealing film. Any contamination or interruption in the fluid supply can compromise the sealing performance. Additionally, these seals may require more precise installation and alignment compared to other seal types.

Conclusion

Understanding the different types of bulkhead shaft seals is crucial for selecting the most appropriate sealing solution for a given application. Mechanical seals, lip seals, pressure-activated composite seals, and non-contacting, hydro-activated seals each have their unique strengths and limitations.

By considering factors such as pressure, temperature, chemical compatibility, and maintenance requirements, engineers and maintenance professionals can make informed decisions that optimize sealing performance and equipment reliability.