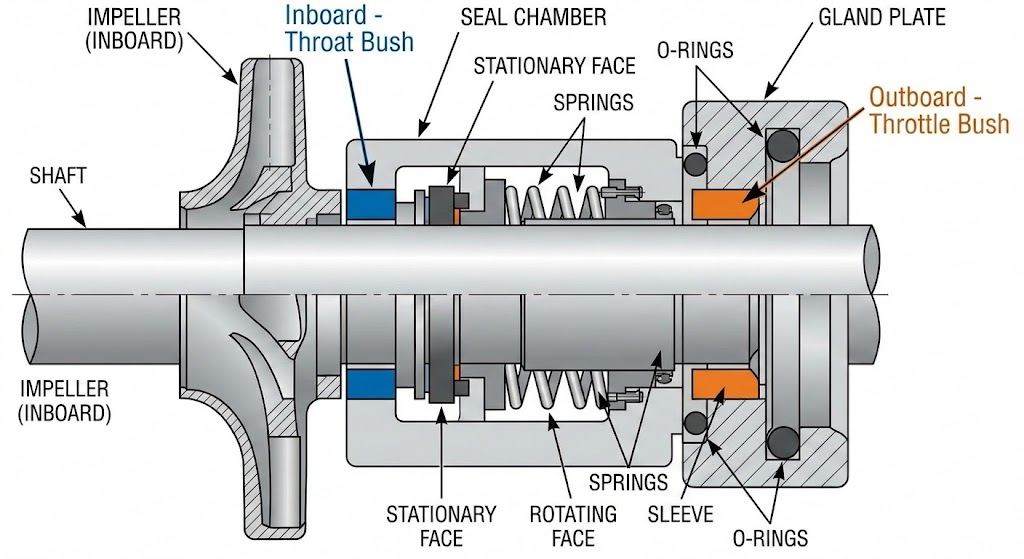

Both “throat bush” and “throttle bush” appear in parts lists and technical documentation, but they occupy different positions in the seal assembly. Confusion arises because they perform similar functions, creating restrictive clearances around the shaft. The difference comes down to location: throat bush sits inboard near the impeller, throttle bush sits outboard in the placa de prensaestopas.

What Is the Difference Between Throat Bush and Throttle Bush?

Position is the definitive differentiator between these two components.

Position-Based Distinction

The throat bush mounts between the impeller and the seal chamber in a pump. It faces the process fluid and controls flow into the seal environment.

The throttle bush mounts at the atmospheric end of the gland plate in mechanical seals. It faces atmosphere and restricts leakage from the seal to the outside.

When examining a seal assembly drawing, identify the impeller side (inboard) versus the atmospheric side (outboard). The throat bush is always inboard; the throttle bush is always outboard.

Quick Reference Comparison Table

| Feature | Throat Bush | Throttle Bush |

|---|---|---|

| Location | Inboard (impeller side) | Outboard (gland plate) |

| Installation | Pressed into casing cover | Pressed into placa de la prensaestopas |

| Primary function | Controls flow from pump to cámara del sello | Restricts leakage from seal to atmosphere |

| Clearance to shaft | 0.015-0.020 inch (0.40-0.51 mm) | Varies by type: 0.007-0.040 inch |

| API reference | API 610/682 | API 682 |

Throat Bush: Function, Location, and Specifications

The throat bush controls fluid flow from the pump chamber into the seal environment. Its clearance directly affects seal chamber pressure and temperature, making it critical for plan de lavado performance.

Location and Installation

The throat bush presses into the casing cover with a 0.002-0.003 inch (0.05-0.08 mm) interference fit. This tight fit to the casing ensures the component stays in position under process pressure differentials.

The clearance to the shaft or sleeve measures 0.015-0.020 inch (0.40-0.51 mm). This gap is engineered to create controlled flow rather than act as a seal.

Primary Functions

Para Plan API 11 applications, the buje de garganta creates optimal pressure in the seal chamber by restricting return flow to the pump suction. Without proper throat bushing clearance, seal chamber pressure drops below design values.

Para Plan API 23 systems, the throat bushing separates the cool seal chamber from the hot process. A properly functioning throat bush maintains a temperature drop of 11-28C (20-50F) between process and seal chamber. When this temperature differential narrows, suspect throat bushing wear.

As noted in industry practice: “The only purpose for a throat bushing is to control the fluid in the seal chamber either to increase pressure (for example a plan 11) or to limit interchange with the pumped fluid (for example a plan 23).”

Clearance Specifications

- Throat bushing to shaft: 0.015-0.020 inch (0.40-0.51 mm) clearance

- Throat bushing to case: 0.002-0.003 inch (0.05-0.08 mm) interference

Verify these specifications against your pump OEM documentation. Clearances outside tolerance indicate replacement is needed.

Materiales

Standard throat bush materials include:

- Stainless steel (general service)

- Bronze (non-sparking applications)

- Carbon (floating types)

- PEEK composites (high-performance, carbon fiber-reinforced)

- Engineered plastics

Select materials based on fluid compatibility and temperature requirements. For material selection guidance, consider both the process fluid and flush media properties.

Throttle Bush: Function, Location, and Specifications

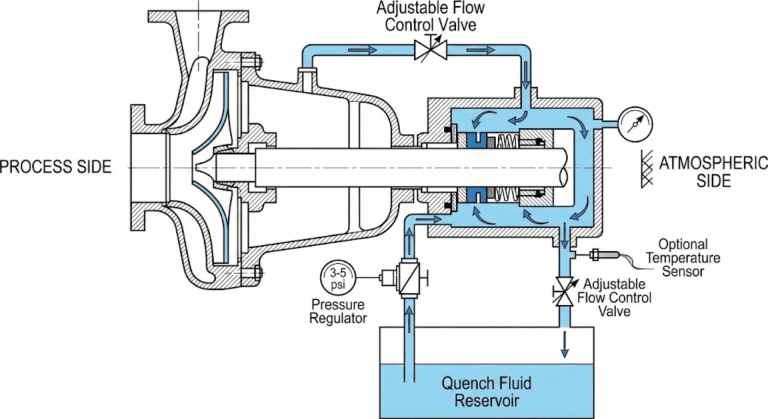

The throttle bush provides secondary containment at the atmospheric end of the seal. It restricts leakage from the seal chamber to atmosphere and enables failure detection in API Plan 66A/B systems.

Location and Installation

The throttle bush presses into the seal gland plate, forming a close clearance around the sleeve. Its position at the atmospheric end means it must tolerate potential dry-running contact with the shaft.

I recommend selecting throttle bush materials that accept occasional shaft contact without galling. Carbon and bronze remain the preferred choices for this reason.

Primary Functions

The throttle bush serves as a containment device. In normal operation, it restricts minor seal weepage from reaching atmosphere. In the event of primary de falla del sello, it limits leakage and provides time for controlled shutdown.

For hydrocarbon applications, secondary containment bushings can restrict leakage at full pipeline pressure. John Crane’s secondary containment bushing, for example, handles up to 1500 psi (103 bar) in failure scenarios.

Clearance Specifications by Bushing Type

| Bushing Type | Diametral Clearance | Aplicación |

|---|---|---|

| Fixed throttle | 0.025-0.040 inch | API Category 1 (default) |

| Floating carbon | 0.007-0.011 inch | API Category 2/3 (default per 4th edition) |

| Segmented | 0.001-0.002 inch effective | Category 2/3 option (tightest) |

Historically, throttle bushings had a nominal 0.025 inch diametral clearance. Modern API 682 editions require tighter clearances for higher reliability categories.

Materiales

Throttle bush materials must be non-sparking and accept dry-running contact:

- Carbon (primary choice: non-sparking, no static buildup)

- Bronze (non-sparking applications)

Avoid materials prone to galling with the shaft or sleeve material.

API 682 Bushing Requirements by Category

API 682 4th edition changed the default bushing requirements. Practitioners trained on earlier editions should update their specifications.

Category Defaults (4th Edition)

| API Category | Default Bushing Type | Notas |

|---|---|---|

| Bombas no API-610 | Fixed throttle bushing | Standard for low-duty applications |

| Bombas API-610 | Floating bushing | Changed from fixed in earlier editions |

| Pruebas/documentación más rigurosas | Floating bushing | Highest reliability requirement |

Fixed vs Floating Bushings

Fixed bushings mount tight in the housing with no radial clearance on the OD. They offer simpler design but cannot accommodate shaft deflection or runout.

Floating bushings have clearance on the OD, allowing radial motion. When shaft deflection occurs, the bushing follows rather than forcing contact. This design reduces galling risk and accommodates dynamic shaft movement.

When to Specify Each Type

For stable shaft operation with minimal deflection, fixed bushings suffice. Specify fixed bushings for Category 1 applications and lower-pressure services.

For pumps with expected shaft deflection, always specify floating bushings. Category 2 and 3 applications require floating bushings by default. The tighter clearances of segmented carbon bushings work best when you need maximum containment with acceptable light rubbing.

Can Throat Bush and Throttle Bush Be Used Interchangeably?

No. These components are designed for different positions and functions. Interchanging them creates operational problems.

Position-Specific Design Considerations

The throat bush is sized to create optimal flow and pressure in the seal chamber for specific API plans. Its clearance works with the pump’s hydraulic characteristics to establish target seal chamber conditions.

The throttle bush is sized for containment and leakage restriction. It must tolerate atmospheric-side conditions including potential dry running. Using a throat bush in the throttle position risks improper containment. Using a throttle bush in the throat position disrupts seal chamber pressure control.

Terminology in Industry Practice

Some contexts use these terms loosely:

- Low-pressure stuffing boxes: “throat bushing” terminology more common

- High-pressure applications: “throttle bushing” terminology preferred

- Slurry pumps: “throat bush” refers to a completely different component (see below)

Always verify position in the parts diagram before ordering. Cross-reference OEM documentation to confirm correct part numbers for your specific application.

Throat Bush in Slurry Pumps: Different Context

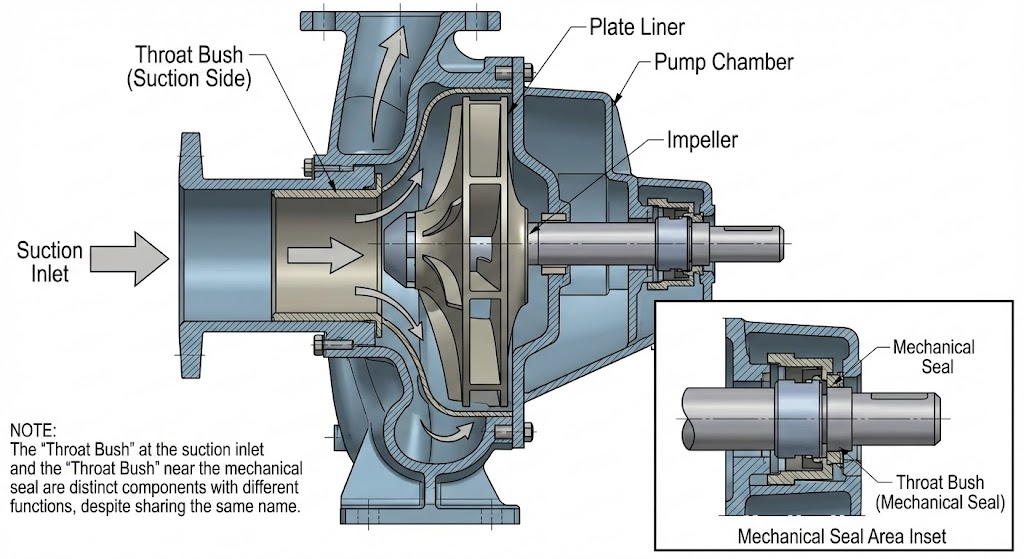

The term “throat bush” has a different meaning in slurry pump applications. Understanding this distinction prevents confusion when working across pump types.

Slurry Pump Throat Bush Location

In slurry pumps, the throat bush locates at the pump suction inlet, not between the impeller and seal. It directs slurry flow to the impeller and forms the pump chamber with the plate liner.

This component is entirely different from the sello mecánico throat bushing discussed in previous sections.

Key Differences from Mechanical Seal Throat Bush

| Aspect | Mechanical Seal Context | Slurry Pump Context |

|---|---|---|

| Location | Between impeller and seal chamber | At pump suction inlet |

| Function | Controls flow to seal | Directs slurry to impeller |

| Wear mode | Erosion from flush fluid | Abrasive wear from slurry |

| Materiales | SS, bronze, carbon | High chrome (Cr27, Cr35), rubber, polyurethane |

Slurry Pump Clearance and Adjustment

Metal slurry pump impeller-to-throat bush gap typically measures 0.5-1 mm. This clearance requires regular adjustment as wear occurs.

Field experience shows that regular impeller adjustment can increase wear life by up to 50%. A worn throat bush reduces pump efficiency by allowing recirculation.

Cómo Identificar la Pieza Correcta para su Bomba

Siga este enfoque sistemático para garantizar la especificación correcta de la pieza.

Paso 1: Localice el Componente en el Dibujo de Ensamblaje

Examine el dibujo en corte transversal. Identifique la posición del impulsor y el extremo atmosférico del prensaestopas.

- Componente interno de las caras del sello = Casquillo de garganta

- Componente externo en la placa del prensaestopas = Casquillo de estrangulación

Paso 2: Consulte el Plan API

El plan de lavado del sello mecánico determina la criticidad del casquillo de garganta:

- Planes 11, 13, 14, 21, 23, 32: El casquillo de garganta es crítico para el control de presión/temperatura

- Planes 66A, 66B: El casquillo de estrangulación en el prensaestopas es para contención y detección de fallos

Paso 3: Verifique los Números de Pieza del Fabricante Original (OEM)

Consulte la documentación del fabricante. Verifique que las especificaciones de holgura cumplan con los requisitos de su categoría API. Los números de pieza por sí solos pueden no distinguir claramente entre casquillos de garganta y de estrangulación, especialmente cuando proveedores externos utilizan convenciones de nomenclatura diferentes.

Paso 4: Especifique Materiales Según la Aplicación

- Proceso estándar: Acero inoxidable o carbono

- Se requiere antichispa: Bronce o carbono

- Servicio con lodos: Aleación de alto cromo o elastómero

Para aplicaciones de alta temperatura, considere seleccionar sellos mecánicos para entornos de alta temperatura al especificar materiales de casquillos compatibles.

Conclusión

La identificación correcta del casquillo comienza con la posición: el casquillo de garganta es interno, el casquillo de estrangulación es externo. Siempre verifique la holgura del casquillo de garganta al reemplazar sellos para evitar fallos repetidos.

Para obtener asistencia en la especificación de casquillos de garganta o estrangulación para su aplicación de sellado, contacte a nuestro equipo de ingeniería.