Of approximately 15 carbon grades used in mechanical seal faces, only three are FDA compliant. The antimony-impregnated carbons common in oil and gas applications are poisonous and unsuitable for pharmaceutical use. Yet you cannot distinguish a compliant seal from a non-compliant one by visual inspection alone.

This traceability gap creates significant risk. A typical API production line contains 15-20 mechanical seals plus 60-100 static sealing joints. Each represents a potential contamination point, regardless of downstream quality assurance. Complex global supply chains routinely strip traceability documentation, and production urgency often prioritizes uptime over compliance verification.

GMP-compliant mechanical seal specification requires integrating three regulatory frameworks: FDA 21 CFR Part 211 for equipment construction, ASME BPE for surface finish requirements, and USP Class VI for material biocompatibility. This guide covers each requirement and provides the documentation framework for regulatory audit readiness.

Understanding FDA 21 CFR Part 211 Equipment Requirements

FDA 21 CFR 211.65 establishes the foundational requirements for pharmaceutical manufacturing equipment, including mechanical seals. The regulation contains two distinct provisions that seal specifiers must address.

The first requirement states: “Equipment shall be constructed so that surfaces that contact components, in-process materials, or drug products shall not be reactive, additive, or absorptive so as to alter the safety, identity, strength, quality, or purity of the drug product.”

The second provision addresses operational substances: “Any substances required for operation, such as lubricants or coolants, shall not come into contact with components, drug product containers, closures, in-process materials, or drug products.”

This dual requirement has direct implications for mechanical seal selection. Contact surfaces – including seal faces, elastomers, and metal components – must meet material compliance standards. But the regulation goes further. Barrier fluids, flush media, and any other operational substances must either be product-compatible or isolated from product contact.

For dual mechanical seals, this means barrier fluid selection is not merely an engineering decision. It carries regulatory weight. If the outer seal fails and barrier fluid contacts the product stream, that barrier fluid becomes part of the contamination risk assessment.

FDA warning letters frequently cite equipment-related violations. The cost of remediation can be substantial, making proactive compliance far more economical than reactive correction.

Related to these requirements, API mechanical seal standards provide additional configuration guidance for pharmaceutical applications.

ASME BPE Surface Finish Requirements

ASME BPE 2022 defines seven surface finish designations (SF0-SF6) for bioprocessing equipment. SF4 electropolished finish has become the pharmaceutical industry standard for product contact surfaces.

| Designation | Ra Max | Finish Method | Typical Application |

|---|---|---|---|

| SF0 | No requirement | As-manufactured | Non-product contact |

| SF1 | 0.51 um (20 uin) | Mechanically polished | Utility systems |

| SF2 | 0.64 um (25 uin) | Mechanically polished | Utility systems |

| SF3 | 0.76 um (30 uin) | Mechanically polished | WFI systems |

| SF4 | 0.38 um (15 uin) | Electropolished | Pharmaceutical product |

| SF5 | 0.51 um (20 uin) | Electropolished | Specialized |

| SF6 | 0.64 um (25 uin) | Electropolished | Specialized |

The distinction between mechanical polishing (SF1-SF3) and electropolishing (SF4-SF6) matters for pharmaceutical applications. Electropolishing removes surface material uniformly through an electrochemical process, creating surfaces smooth enough that fluids or solids cannot accumulate. This prevents contamination and corrosion buildup in ways mechanical polishing cannot match.

For pharmaceutical seal components, Ra 0.4-0.8 um is typical depending on sterilization requirements. The SF4 designation (Ra max 0.38 um electropolished) provides margin for the most demanding applications.

External surfaces that do not contact product may use SFT1 or SFT4 designations, which allow Ra max 0.8 um. This distinction allows cost optimization while maintaining compliance where it matters.

These surface requirements align with sanitary seal standards used in food and beverage applications, though pharmaceutical specifications are typically more stringent.

USP Class VI Material Certification

USP Class VI represents the strictest plastics classification for biocompatibility testing. However, a common misunderstanding creates compliance gaps: Class VI applies to the material, not the final part.

The USP Chapter <87> and <88> testing protocol subjects material extracts to three in-vivo tests at escalating temperature and time conditions:

- 50C for 72 hours

- 70C for 24 hours

- 121C for 1 hour

Each condition evaluates:

- Acute Systemic Toxicity: Irritant effects and human hazard potential

- Intracutaneous Test: Direct tissue administration response

- Implantation Test: Five-day tissue response evaluation

Class VI certification at a given temperature means the material passed all three tests at that extraction condition. A material certified at 121C has demonstrated biocompatibility under conditions simulating steam sterilization exposure.

The critical gap occurs between material certification and part qualification. If a USP Class VI certified O-ring is manufactured, handled, or stored in a non-cleanroom environment, it may be disqualified from pharmaceutical use despite the material certification. Traceability documentation must extend from raw material through final installation.

This is where carbon grade selection becomes critical. Of approximately 15 carbon grades commonly used in seal faces, only three meet FDA compliance requirements. Antimony-impregnated carbons – widely used in oil and gas applications for their favorable friction characteristics – contain toxic elements unsuitable for pharmaceutical product contact.

Seal Face Material Selection

Silicon carbide paired with silicon carbide (SiC/SiC) has become the de-facto standard for pharmaceutical mechanical seals. The material combination offers exceptional chemical resistance, thermal conductivity, and wear characteristics that support CIP/SIP protocols.

For seal face materials, the distinction between sintered and reaction-bonded silicon carbide carries significant implications for pharmaceutical applications.

Direct sintered silicon carbide (SSiC) contains no free silicon. This absence provides superior chemical resistance even at pH extremes above 11. For applications involving aggressive cleaning agents or variable pH processes, sintered SiC is the preferred choice.

Reaction-bonded silicon carbide (RBSiC) contains 8-12% free silicon metal in the final product. This free silicon limits chemical resistance – the material should not be used with pH below 4 or above 11, and strong acids and bases should be avoided.

The SiC material provides exceptional hardness (9-9.5 on the Mohs scale) and thermal conductivity of approximately 120 W/mK. These properties support the high-speed, high-temperature conditions common in pharmaceutical processing.

For carbon-based seal faces, material selection requires even greater scrutiny. I’ve seen dozens of installations fail traceability audits because maintenance teams installed replacement seals sourced through general industrial distributors. The carbon looked identical. The paperwork told a different story.

Without traceability documentation clearly stated on the packaging, you simply cannot differentiate between a compliant and non-compliant seal visually. This makes supply chain management as critical as initial specification.

Elastomer Selection for CIP/SIP Compatibility

EPDM has become the standard elastomer for pharmaceutical water and CIP applications due to its FDA 21 CFR 177.2600 compliance and steam resistance. However, understanding temperature limits prevents specification errors in demanding SIP applications.

| Elastomer | Max Temp (Steam) | FDA Compliant | USP Class VI | CIP/SIP Suitability |

|---|---|---|---|---|

| EPDM | 150C (with O2) | Yes | Available | Standard choice |

| FFKM | 230C+ | Yes | Available | Intensive SIP |

| FKM | 125-140C | Yes | Available | Limited SIP use |

| HNBR | 125-140C | Varies | Varies | Not recommended |

| VMQ (Silicone) | – | Yes | Available | Poor CIP resistance |

EPDM provides reliable performance up to 150C in the presence of atmospheric oxygen, extending to 200C in oxygen-free environments. For most pharmaceutical applications with SIP temperatures between 121C and 134C, EPDM offers cost-effective performance.

When SIP temperatures approach or exceed 140C, EPDM reaches its performance limit. FFKM (perfluoroelastomer) grades operating at temperatures up to 230C become necessary. The significant cost premium for FFKM – often 10-20x EPDM pricing – justifies careful analysis of actual SIP conditions rather than conservative over-specification.

FKM and HNBR exceed their performance limits at typical SIP temperatures and are generally unsuitable for pharmaceutical steam sterilization. Silicone rubber (VMQ), despite FDA compliance, demonstrates poor resistance to CIP cleaning agents.

For detailed elastomer selection guidance, material compatibility with specific cleaning and sterilization chemistries should drive the final decision.

Single vs Dual Seal Configuration for Pharmaceutical Processing

EHEDG (European Hygienic Engineering & Design Group) classification determines whether single or dual mechanical seals meet application requirements. The distinction between hygienic and aseptic processing carries significant design implications.

EHEDG Hygienic Equipment Class I and II covers most pharmaceutical processing where product is subsequently sterilized or where the environment permits controlled bioburden. Single mechanical seals with appropriate materials and surface finishes meet these requirements when properly specified.

EHEDG Aseptic Class applies to processing where no ingress of micro-organisms is permitted. For aseptic processing, dual seals with sterile barrier fluid are required. The barrier fluid creates a secondary containment zone that prevents atmospheric contamination even if the product-side seal experiences minor degradation.

This classification-based approach prevents both over-specification (unnecessary dual seals adding cost and complexity) and under-specification (single seals in true aseptic applications).

When dual seals are required, FDA 21 CFR 211.65 constrains barrier fluid selection. The barrier fluid must either be product-compatible (acceptable if it contacts the product stream through inner seal failure) or a separate containment system must prevent any possibility of product contact.

Metal bellows seals often provide advantages in pharmaceutical dual-seal configurations due to their elimination of elastomer dynamic sealing elements on the product side.

Gas-Lubricated Seals for Sterile Applications

The trend toward “oil-free” pharmaceutical manufacturing is driving adoption of gas-lubricated mechanical seals, particularly in dryer applications where barrier fluid contamination presents unacceptable risk.

Gas-lubricated seals operate on a fundamentally different principle than liquid-lubricated designs. Inert gas (typically nitrogen) enters spiral grooves on the rotating seal face outer diameter. As the shaft rotates, the gas compresses through narrowing grooves, creating film pressure that provides an opening force slightly greater than the closing forces. The faces separate without contact, eliminating both wear and contamination from barrier fluid.

At Merck KGaA in Darmstadt, Germany, 16 paddle dryers have been equipped with gas-lubricated mechanical seals. The installation eliminated barrier fluid contamination risk entirely while providing 100% product purity through nitrogen lubrication.

The technology is not universally applicable. Gas seals require clean, dry gas supply; appropriate seal chamber design; and operating conditions within the seal’s design envelope. For dryers, reactors, and other equipment where barrier fluid ingress presents product contamination risk, gas-lubricated technology merits serious evaluation.

Validation Documentation Requirements (IQ/OQ/PQ)

Equipment qualification for pharmaceutical manufacturing follows a structured IQ/OQ/PQ protocol. Mechanical seals, while sometimes overlooked in validation planning, require the same documentation rigor as major equipment systems.

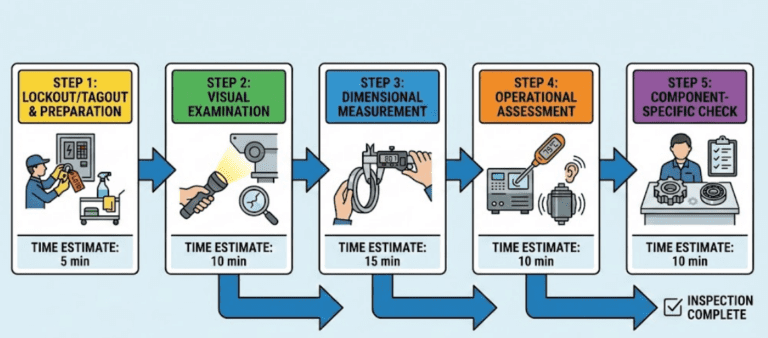

Installation Qualification (IQ) verifies that equipment has been installed according to manufacturer specifications. For mechanical seals, IQ documentation includes:

- Seal identification and serial number verification

- Material certificates for all wetted components

- Surface finish certifications

- Dimensional verification against seal drawing

- Installation torque and compression settings

Operational Qualification (OQ) tests equipment function under boundary and worst-case conditions to establish process control limits. Seal OQ documentation addresses:

- Leak-free operation across operating temperature range

- CIP cycle performance verification

- SIP cycle performance verification

- Flush system function (if applicable)

Performance Qualification (PQ) demonstrates consistent results under normal operating conditions over an extended period. For seals, PQ typically runs concurrently with process PQ and documents continued leak-free operation.

These phases must occur in sequence. Re-qualification is required after major maintenance or modification. Seal replacement using identical certified components typically requires abbreviated documentation, while any change in seal configuration or materials triggers full re-qualification.

Material traceability per Regulation EC 1935/2004 extends these documentation requirements back through the supply chain. Each material must be traceable from raw material through processing, manufacturing, and installation. For an API production line with 15-20 mechanical seals and 60-100 static sealing joints, this traceability burden is substantial but necessary.

The cost of inadequate documentation becomes clear during regulatory inspections. Equipment-related violations can result in warning letters, and remediation typically requires substantial investment – making proactive compliance far more economical than reactive correction.

Bringing It Together

GMP-compliant mechanical seal specification integrates regulatory requirements, material science, and validation documentation into a unified framework. FDA 21 CFR Part 211 establishes the foundational requirement for both contact surfaces and operational substances. ASME BPE defines surface finish standards, with SF4 electropolished finish serving most pharmaceutical applications. USP Class VI testing confirms material biocompatibility, while supply chain traceability ensures that certified materials reach installation with documentation intact.

The carbon grade compliance issue illustrates why traceability matters. Only 3 of approximately 15 carbon grades meet FDA requirements, yet non-compliant and compliant seals are visually identical. Without documentation from raw material through installation, compliance cannot be verified.

Material selection follows predictable patterns: SiC/SiC seal faces for chemical resistance and thermal performance, EPDM elastomers for standard CIP/SIP, FFKM for intensive sterilization above 140C. Seal configuration – single versus dual – follows EHEDG classification rather than conservative over-specification. And for applications where barrier fluid presents contamination risk, gas-lubricated technology offers complete elimination rather than just mitigation.

The practical next step is applying this framework to your specific installation. Review your current seal specifications against FDA, ASME BPE, and USP requirements. Verify traceability documentation exists from raw material through installation. And confirm that your validation protocols address mechanical seals with the same rigor applied to major equipment systems.