Grundfos Mechanical Seal

Grundfos mechanical seals are high-quality, reliable sealing solutions designed specifically for Grundfos pumps. These mechanical shaft seals ensure optimal pump performance by preventing leakage and maintaining system efficiency. Our Grundfos mechanical seal replacements are engineered to meet or exceed OEM specifications, providing a cost-effective alternative without compromising on quality or performance.

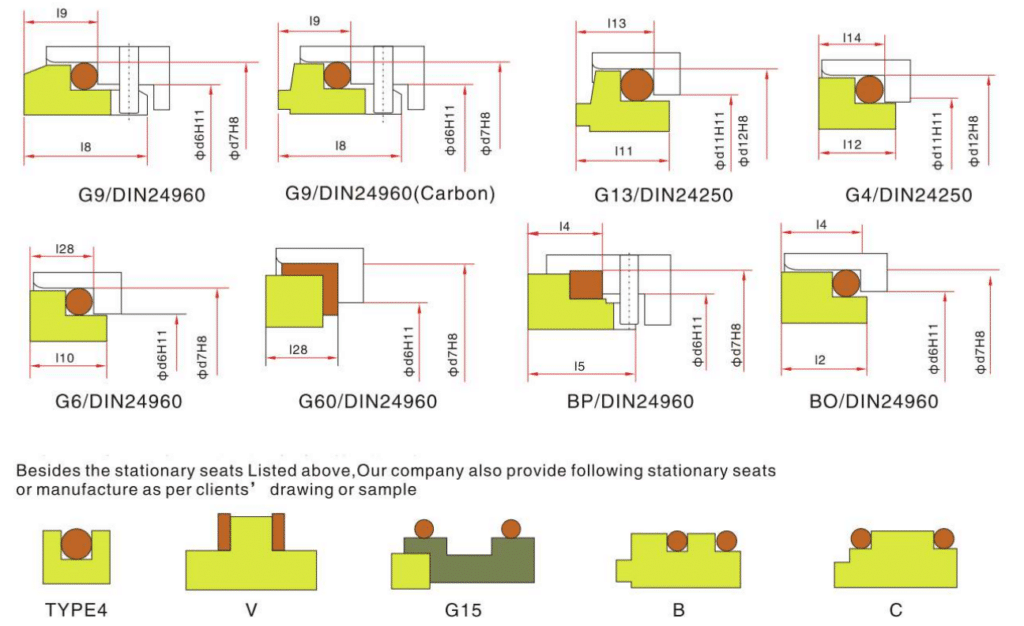

Mechancial seal drawing

Mechancial seal Chart

| Shaft | d6 | d7 | d11 | d12 | l2 | l4 | l5 | l8 | l9 | l10 | l11 | l12 | l13 | l14 | l28 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 17 | 21 | 15.5 | 19.2 | 12 | 14 | 15 | 17.5 | 10 | 7.5 | 9 | 7.5 | 7.1 | 6.6 | 6.6 |

| 12 | 17 | 21 | 15.5 | 19.2 | 12.8 | 12 | 18.5 | 17.5 | 10 | 7.5 | 10 | 6.5 | 7.6 | 5.6 | 6.6 |

| 14 | 19 | 23 | 17.5 | 21.6 | 13 | 12 | 18.5 | 17.5 | 10 | 7.5 | 10 | 6.5 | 7.6 | 5.6 | 6.6 |

| 16 | 21 | 25 | 20.5 | 24.6 | 12.8 | 12 | 18.5 | 17.5 | 10 | 7.5 | 11 | 7.5 | 8.6 | 6.6 | 7.5 |

| 18 | 27 | 33 | 24 | 30 | 14.5 | 13.5 | 20.5 | 19.5 | 11 | 8.5 | 12.5 | 9 | 10 | 8 | 7.5 |

| 20 | 29 | 35 | 29.5 | 35 | 14.5 | 13.5 | 20.5 | 19.5 | 11 | 8.5 | 12.5 | 9.5 | 10 | 7.5 | 7.5 |

| 22 | 31 | 37 | 29.5 | 35 | 14.5 | 13.5 | 20.5 | 19.5 | 11 | 8.5 | 12.5 | 9.5 | 10 | 7.5 | 7.5 |

| 24 | 33 | 39 | 32 | 38 | 14.3 | 13.3 | 20.3 | 19.5 | 11 | 8.5 | 12.5 | 8.5 | 9.5 | 7.5 | 7.5 |

| 26 | 35 | 40 | 34 | 40 | 14 | 13 | 20 | 19.5 | 11.5 | 8.5 | 13 | 9 | 10 | 8 | 7.5 |

| 28 | 37 | 43 | 36 | 42 | 13.5 | 12.5 | 19.5 | 19.5 | 11.5 | 8.5 | 14 | 10 | 11 | 9.5 | 7.5 |

| 30 | 39 | 45 | 39 | 45 | 13 | 12 | 19 | 19.5 | 11.5 | 8.5 | 14 | 11 | 11 | 10.5 | 7.5 |

| 32 | 42 | 48 | 42.2 | 48 | 13 | 12 | 19 | 19.5 | 11.5 | 8.5 | 14 | 11.5 | 11 | 10.5 | 7.5 |

| 35 | 44 | 50 | 46.2 | 52 | 13 | 12 | 19 | 19.5 | 11.5 | 8.5 | 14.5 | 12 | 11.5 | 11 | 7.5 |

| 38 | 49 | 56 | 49.2 | 55 | 14 | 13 | 20 | 22 | 14 | 10 | 14.5 | 11.3 | 11.5 | 10.3 | 9 |

| 40 | 51 | 58 | 51 | 58 | 14 | 13 | 20 | 22 | 14 | 10 | 14.5 | 12 | 11.5 | 10.8 | 9 |

| 42 | 54 | 61 | 53.3 | 62 | 14 | 13 | 20 | 22 | 14 | 10 | 17 | 13.2 | 14.3 | 12 | 9 |

| 45 | 56 | 63 | 55.3 | 64 | 14 | 13 | 20 | 22 | 14 | 10 | 17 | 13.2 | 14.3 | 12 | 9 |

| 48 | 59 | 66 | 59.7 | 68.4 | 14 | 13 | 20 | 22 | 14 | 10 | 17 | 12.8 | 14.3 | 11.6 | 9 |

| 50 | 60 | 70 | 60.8 | 69.9 | 14.5 | 13.5 | 20.5 | 23 | 15 | 10.5 | 17 | 12.4 | 14.3 | 11.6 | 9.5 |

| 53 | 65 | 73 | 63.8 | 72.3 | 14.5 | 13.5 | 20.5 | 23 | 15 | 12 | 18 | 13.5 | 15.3 | 12.3 | 11 |

| 55 | 67 | 75 | 66.5 | 75.4 | 14.5 | 13.5 | 20.5 | 23 | 15 | 12 | 18 | 14.5 | 15.3 | 13.3 | 11 |

| 58 | 70 | 78 | 69.6 | 78.4 | 14.5 | 13.5 | 20.5 | 23 | 15 | 12 | 18 | 14.5 | 15.3 | 13.3 | 11 |

| 60 | 72 | 80 | 71.5 | 80.4 | 14.2 | 13.5 | 20.5 | 23 | 15 | 12 | 18 | 14.5 | 15.3 | 13.3 | 11 |

| 63 | 75 | 83 | 74.5 | 83.4 | 14.2 | 13.5 | 20.5 | 23 | 15 | 12 | 18 | 14.2 | 15.3 | 13.7 | 11 |

| 65 | 77 | 85 | 76.6 | 85.4 | 14 | 13.5 | 20.5 | 23 | 15 | 12.5 | 19 | 14.9 | 16 | 13.7 | 11.3 |

| 68 | 81 | 90 | 82.7 | 91.5 | 14.2 | 13.5 | 20.5 | 25 | 18 | 12.5 | 19 | 14.2 | 15 | 13.7 | 11 |

| 70 | 83 | 92 | 83.3 | 93.2 | 14.5 | 14 | 21.5 | 25 | 18 | 12.5 | 19 | 14.6 | 16 | 14.3 | 11.3 |

| 75 | 88 | 97 | 90.2 | 99 | 15.2 | 14.5 | 21.5 | 26 | 18 | 12.5 | 19 | 15.2 | 15.3 | 14.8 | 11.3 |

| 80 | 95 | 105 | 95.2 | 104 | 15.7 | 15 | 22 | 26.2 | 18.2 | 13 | 19 | 16.2 | 16.3 | 14.8 | 12 |

| 85 | 100 | 110 | 100.2 | 109 | 15.7 | 15 | 22 | 26.2 | 18.2 | 15 | 19 | 16 | 16.3 | 14.8 | 14 |

| 90 | 105 | 115 | 105.2 | 114 | 15.7 | 15 | 22 | 26.2 | 18.2 | 15 | 19 | 16 | 16.3 | 14.8 | 14 |

| 95 | 110 | 120 | 110.6 | 119.4 | 15.7 | 15 | 22 | 26.2 | 17.2 | 15 | 17 | 15.8 | 17 | 15.8 | 14 |

| 100 | 115 | 125 | 114.5 | 123.3 | 15.7 | 15 | 22 | 26.2 | 17.2 | 15 | 17 | 15.8 | 17 | 15.8 | 14 |

Key features

- Precision-engineered to match Grundfos pump requirements

- Easy to install and replace

- Excellent sealing capabilities for minimal leakage

- High wear resistance for extended seal life

- Compatible with a wide range of Grundfos pump models

Materials of construction

- Seal faces: Silicon carbide, tungsten carbide, carbon graphite

- Elastomers: EPDM, FKM (Viton), NBR

- Metal parts: Stainless steel AISI 316, brass

Operating limits

- Temperature range: -20°C to +120°C

- Pressure range: Vacuum to 25 bar

- pH range: 2-12

- Shaft speed: Up to 3600 RPM

Applications

- Water supply and pressure boosting

- Heating, ventilation, and air conditioning (HVAC) systems

- Industrial process cooling and heating

- Wastewater treatment

- Irrigation and agriculture

Interchangeability

Direct replacement for Grundfos CR, CRI, CRN, CHI, CH, CHN, LP, LM series pumps

FAQs

- Identify your Grundfos pump model and serial number

- Refer to the pump’s technical documentation or contact our support team for assistance in selecting the appropriate seal model

With proper installation and maintenance, Grundfos mechanical seals can last for several years, depending on the application and operating conditions

- Replace the seal when signs of leakage or decreased performance are observed

- Preventive maintenance schedules may also recommend seal replacement at specific intervals based on the application

- Installation should be performed by a qualified professional to ensure proper fitting and optimal performance

- Refer to the seal’s installation instructions and the pump’s service manual for guidance