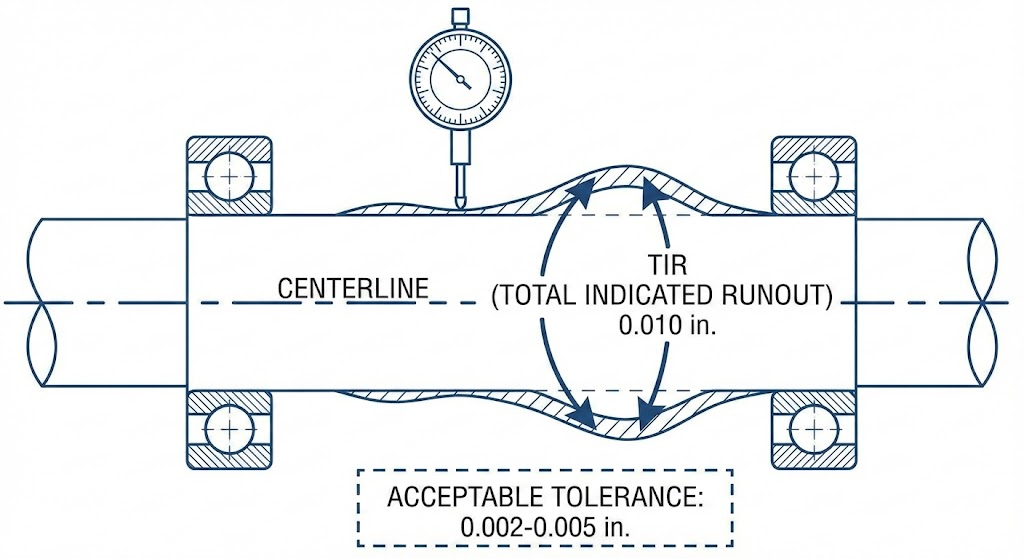

A multi-stage split case boiler feed pump kept failing seals every few months. After multiple replacements, disassembly revealed the root cause: the shaft was bent by 0.034″ TIR—17 times the acceptable tolerance. A single pre-installation check would have caught this before any seal was installed.

Split case pumps present a unique challenge: once the casing halves close, you lose visibility and adjustment ability. Generic seal installation procedures assume continuous access during installation. They skip the verification step that matters most for split case configurations.

Why Split Case Pumps Require Different Procedures

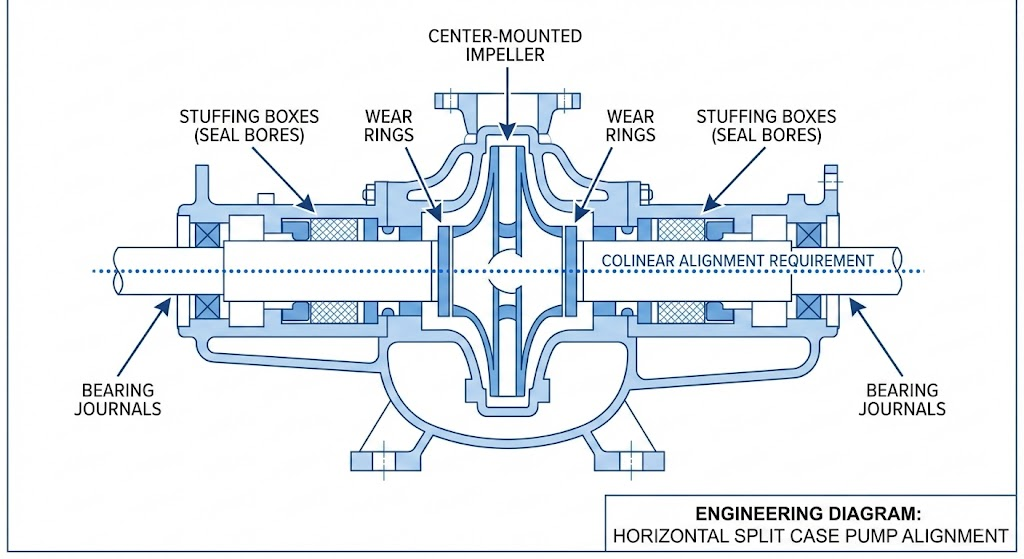

When you open a horizontal split case pump, you see the shaft with a center-mounted impeller. On each side of the impeller are wear rings sitting in bores. Outside of those are the stuffing boxes (seal bores), and beyond those are the bearing journals—also bores. All of these bore centers need to be colinear, meaning aligned in a straight line.

The stuffing boxes are machined surfaces that cannot be adjusted. They serve as fixed reference points. If bearing journals are misaligned relative to the stuffing boxes, the shaft will deflect at the seal location, causing accelerated wear and premature failure.

The most common mistake I see is treating split case installation like end-suction pump work. With end-suction pumps, you can adjust seal compression after the pump is assembled. With split case pumps, once those casing halves come together, you are committed. Any misalignment, improper compression, or contamination becomes locked in.

Pre-Installation Verification

Before you start seal installation, complete these checks. Skipping them means you will be back doing the job again within weeks.

Shaft Runout Measurement

Mount a dial indicator on a stable base and position it at the seal mounting location. Rotate the shaft slowly by hand through one full revolution while recording the Total Indicated Runout (TIR).

Acceptable tolerances:

- Standard pumps: 0.002 to 0.005 inches (0.05-0.13 mm) TIR

- High-speed pumps above 3,600 RPM: 0.001 to 0.002 inches TIR

- API 610 specification: maximum 0.002-inch shaft deflection at seal faces

Shaft runout degrades seal performance through five mechanisms: increased leakage, accelerated face wear, vibration transmission, seal face separation, and reduced component lifespan. If you skip this step, you will be back in a week replacing a seal that never had a chance.

Surface Condition Checks

Inspect the shaft sleeve or shaft surface at the seal location:

- Static surface maximum: 45 RMS finish

- Dynamic surface maximum: 32 RMS finish

- Shaft straightness: cannot exceed 0.05 mm

Check for scoring, corrosion, or wear marks. Any damage here will tear O-rings during installation or allow leakage past secondary seals. Run your fingernail across the surface—if you feel ridges, the surface needs reconditioning.

Seal Installation Sequence

Component Seal Installation

For component seals in split case pumps, the sequence matters because you are working with limited access once the rotor assembly is positioned.

Apply a light film of compatible lubricant to shaft O-ring contact areas. Avoid liberal application—excess lubricant can cause elastomer blistering and swelling. The rubber seal is a static seal; it requires a tight fit to keep spring seat pressure from causing shaft slippage.

Slide the rotary unit onto the shaft, positioning it at the correct setting length per manufacturer specifications. For single-spring seals, compress the spring 50-70% from free length. For multi-spring designs, target approximately 90% compression.

Install the stationary seat in the gland plate. Handle seal faces by edges only—fingerprints on lapped faces introduce contamination that causes immediate wear patterns.

Cartridge Seal Installation

Cartridge seals offer advantages for split case applications because the seal arrives pre-set to the correct compression. The tabs lock the seal at its ideal running length.

Slide the cartridge assembly onto the shaft with setting tabs in place. Position the gland plate and hand-tighten bolts in a cross pattern. Do not remove setting tabs yet—they stay in place until after casing reassembly.

The Pre-Close Verification Step

This verification step is what makes the difference between a seal that fails in months and one that runs for years.

Split case pumps have seal chambers on both sides of the impeller. Problems at one seal affect the other. At a power plant, repeated seal failures on a split case cooling water pump were traced to air entrapment at the top of the upper seal chamber—there was no air vent connection. The lower seal failed because mechanics used incorrect lubricant, causing elastomer swelling.

Complete this checklist before casing closure:

- Seal face alignment: Confirm the stationary face sits square in the gland plate. Check with a straightedge or feeler gauge.

- Compression verification: For component seals, measure installed spring length against specification. For cartridge seals, verify tabs are intact and seated.

- O-ring position: Visually confirm all secondary seals are seated in their grooves. A displaced O-ring will leak immediately on startup.

- Clearances: Verify the rotating assembly does not contact the stationary seat. Rotate the shaft by hand—it should turn freely with slight spring resistance.

- Lubrication check: Confirm faces have adequate lubricant film. Dry startup destroys seals within seconds.

- Vent and drain connections: If the pump uses dual seals or requires API flush plans, verify piping connections are complete and open.

Once the casing closes, you cannot verify any of these items without disassembly.

Casing Reassembly and Final Checks

The casing bolt torque sequence directly affects seal compression. Uneven torque creates casing distortion that changes seal face loading.

Use a three-pass criss-cross pattern:

- First pass: 30% of final torque

- Second pass: 60% of final torque

- Third pass: 100% of final torque

Here is a trick that saves time and prevents leaks: leave the casing gasket long at the stuffing box area until the upper case is torqued down. The point where the gland gasket crosses the casing gasket is a difficult spot to seal. Cut off that tab of gasket material with a razor blade after the upper casing is installed. This ensures a clean seal interface without gaps.

After casing reassembly:

- For cartridge seals, remove setting tabs only after the gland plate is fully secured

- Rotate the shaft by hand to verify free movement

- Check shaft runout again at the coupling end—reassembly can introduce new misalignment

Conclusion

Create your own pre-close verification checklist based on your specific pump and seal configuration. The five minutes spent on verification before closing the casing prevents the hours of repeat work when a seal fails within its first month.

Before you close that casing, verify everything you will not be able to see after. Shaft runout under 0.002″ TIR, proper compression, seated O-rings, free rotation, adequate lubrication. These checks are not optional for split case pumps—they are the difference between a seal that runs for years and one that fails before the first maintenance cycle.