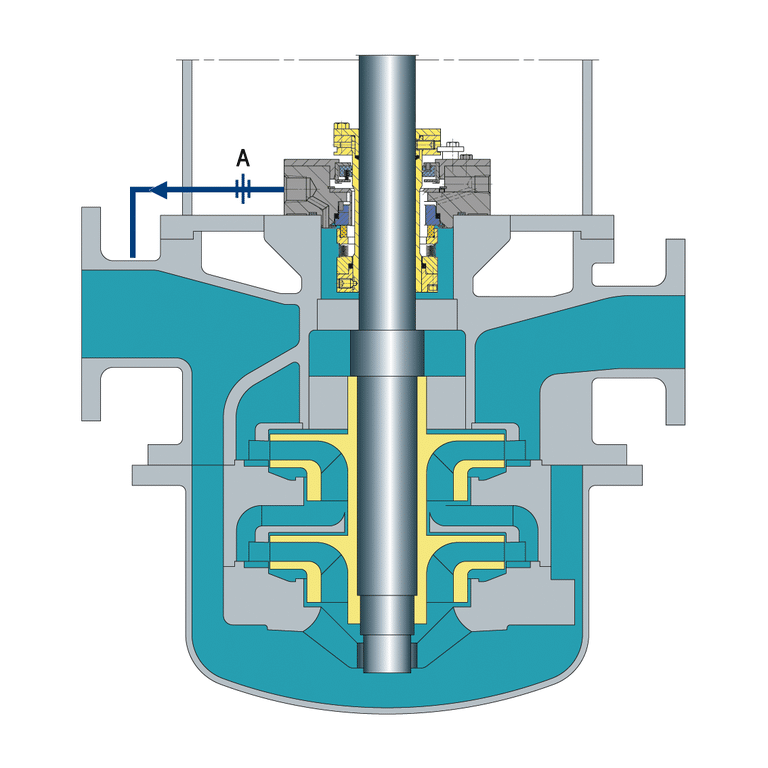

Seal-related repairs account for 60-70% of all centrifugal pump maintenance work. Grundfos pumps are no exception—and replacing the shaft seal yourself can save significant downtime and service costs. The key is following model-specific procedures with the correct torque values and inspection steps.

Before you start, make sure you have the correct seal kit and tools for your specific Grundfos model. The most common mistake I see is technicians rushing into disassembly without verifying they have the right parts.

Tools and Parts Required

Gather these items before draining the pump:

Essential tools:

- 2.5 mm Allen key (for seal securing screws)

- Grundfos shaft seal key 00SV2007, or a 36 mm deep socket (either works)

- Torque wrench capable of 35 Nm

- Dial indicator with magnetic base

- Clean rags and lint-free cloths

- Emery cloth holder (usually included in seal kit)

- Spray bottle with soapy water

Replacement parts:

- Shaft seal kit matching your pump model

- New O-rings and gaskets (included in quality seal kits)

The specialty Grundfos tool 00SV2007 provides better grip, but a standard 36 mm deep socket achieves the same 35 Nm torque specification. Use whichever you have available.

Identifying the Correct Replacement Seal

Check your pump nameplate for the model number and product code. Grundfos uses these to specify the exact seal configuration. For CR series pumps (CR 1, 3, 5, 10, 15, 20), the product code contains the seal variant designation.

| Pump Series | Common Shaft Sizes | Seal Style |

|---|---|---|

| CR 1-5 | 12 mm, 16 mm | Cartridge |

| CR 10-20 | 22 mm | Cartridge |

| MQ 3-35, 3-45 | Part #96450696 | Shaft seal kit |

OEM vs compatible seals: Both work if specifications match. Quality compatible seals use the same materials—silicon carbide faces have been standard on Grundfos cartridge seals since 2004. The key is matching exact dimensions and material grades.

Cartridge seals cost two to three times more than component seals, but they eliminate installation errors that cause premature failure. For technicians who replace seals occasionally, cartridge seals are worth the premium.

Removing the Old Seal

Disconnect power and drain the pump completely. Remove the motor and coupling to access the seal chamber.

For CR series pumps:

- Loosen the seal securing screws (2.5 mm Allen) by 1/4 turn—do not remove them completely

- Using the 00SV2007 tool or 36 mm socket, unscrew the shaft seal counterclockwise

- Pull the old seal straight off the shaft

Before installing the new seal, inspect the shaft surface carefully. I once saw a technician install a brand-new seal only to have it leak immediately. The problem? The old seal had spun on the shaft, cutting grooves into the sleeve. That repair cost double—new seal plus shaft sleeve replacement.

Check these items before proceeding:

- Shaft surface: no scoring, grooves, or corrosion

- Shaft runout: measure with a dial indicator at the seal location

- Acceptable runout: below 0.002-0.005 inches (0.05-0.13 mm)

If runout exceeds 0.005 inches, the pump needs bearing work before seal installation. Installing a new seal on a shaft with excessive runout guarantees early failure.

Installing the New Seal

Preparing the Shaft and Seal

Clean the shaft thoroughly using the emery cloth holder provided with the seal kit. Remove any burrs or sharp edges that could damage O-rings during installation.

Never touch the seal faces with bare fingers. A single fingerprint deposits enough oil to cause fouling between the two precision-lapped surfaces. The seal faces are flat to within one helium light band—about 0.3 microns. Even minor contamination creates gaps large enough for visible leakage.

Spray soapy water on the shaft and all O-ring surfaces. This lubricates without leaving residue.

Mounting the Seal

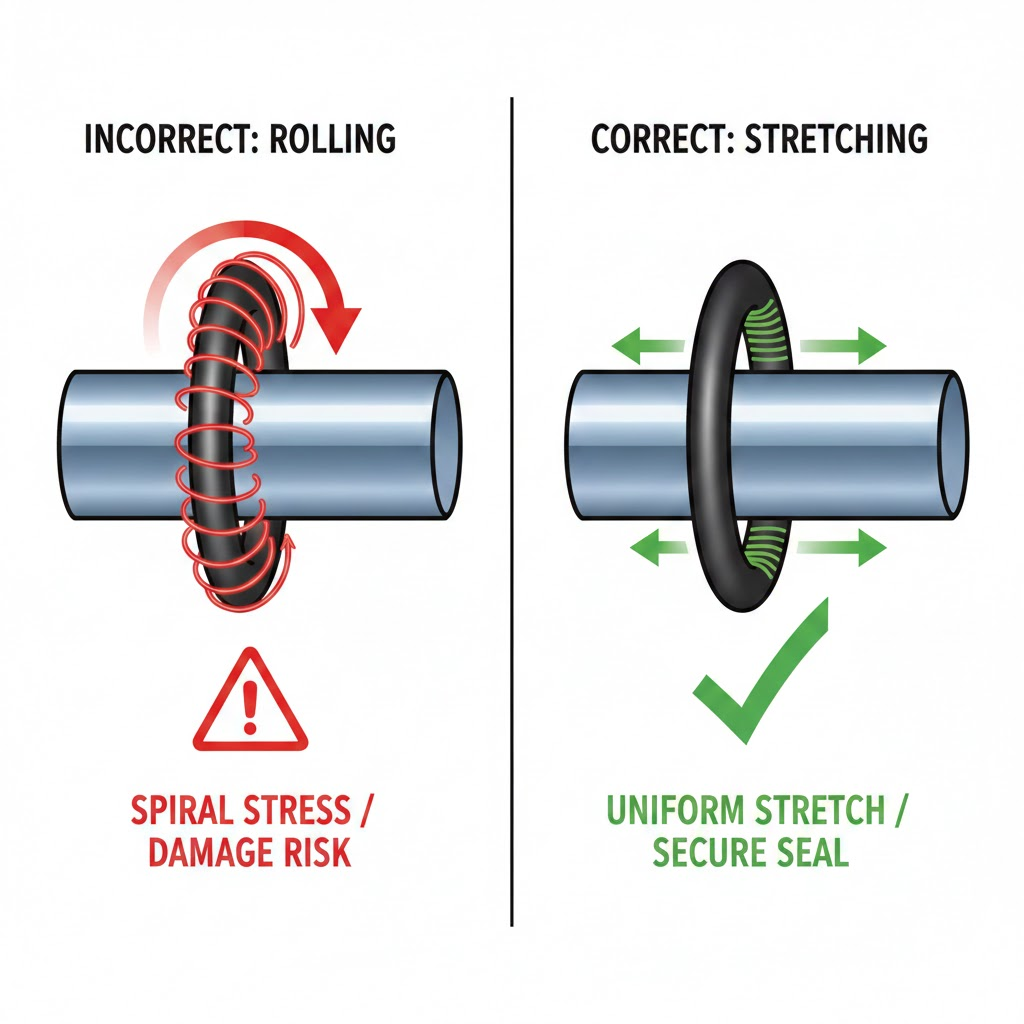

Slide the new Grundfos seal onto the shaft, keeping it square to the shaft axis. Here’s a trick that saves time: stretch O-rings uniformly rather than rolling them down the shaft. Rolling creates spiral stress patterns that cause premature failure at 45-degree angles.

O-rings should stretch no more than 50% during installation. If an O-ring requires excessive force, check that you have the correct size and that the shaft is properly lubricated.

Critical step: If your seal kit includes a spacer or shipping bracket, remove it before startup. I’ve seen rushed installations where the technician left the spacer in place. The result? Immediate seal damage and a complete redo.

Setting the Correct Torque

Tighten the shaft seal to 35 Nm (26 ft-lbs) for CR series pumps. Under-torquing allows the seal to slip; over-torquing distorts the seal housing.

| Component | Torque Specification |

|---|---|

| Shaft seal | 35 Nm |

| Chamber stack | 15 Nm |

| Splined clamp nut | 22 Nm |

Use a calibrated torque wrench—guessing leads to premature failure.

Startup and Verification

Reassemble the pump and coupling. Before starting, verify that the seal chamber can flood properly. Never run a mechanical seal dry, even for a few seconds.

Startup procedure:

- Open suction and discharge valves

- Vent the pump casing to remove air

- Start the pump and observe the seal area

- A small amount of initial weeping is normal

MQ series note: If you’re using an MQ pump as a booster, limit inlet pressure to 30 PSI or less. Grundfos engineers recommend this restriction to prevent seal gasket failure from excessive pressure differential.

If the seal leaks after startup: Resist the urge to tighten the gland bolts. Over-tightening distorts the seal components and worsens the leak. The correct response is often to loosen slightly and allow the faces to seat properly.

Next Steps

Monitor the seal closely for the first 24 hours of operation. New seals typically “break in” during this period—minor initial weeping that stops within a few hours is normal.

Schedule a follow-up inspection at 48 hours. If leakage persists beyond the break-in period, check shaft runout and seal face condition rather than simply tightening bolts. Most installation failures trace back to skipped preparation steps, not defective seals.

If you skip the shaft inspection, you’ll be back in a week replacing the same seal.