Last month, a maintenance technician at a chemical plant replaced a pump’s mechanical seal three times in six weeks. Frustrated and confused, he finally called the manufacturer. The diagnosis? His bearings were shot, causing shaft runout that destroyed every new seal within days.

This confusion between mechanical seals and bearings costs facilities millions in unnecessary repairs each year. Here’s the thing: 60-70% of centrifugal pump maintenance involves seals, while 33% of pump failures trace back to bearing problems. These two components work side by side, but they do completely different jobs.

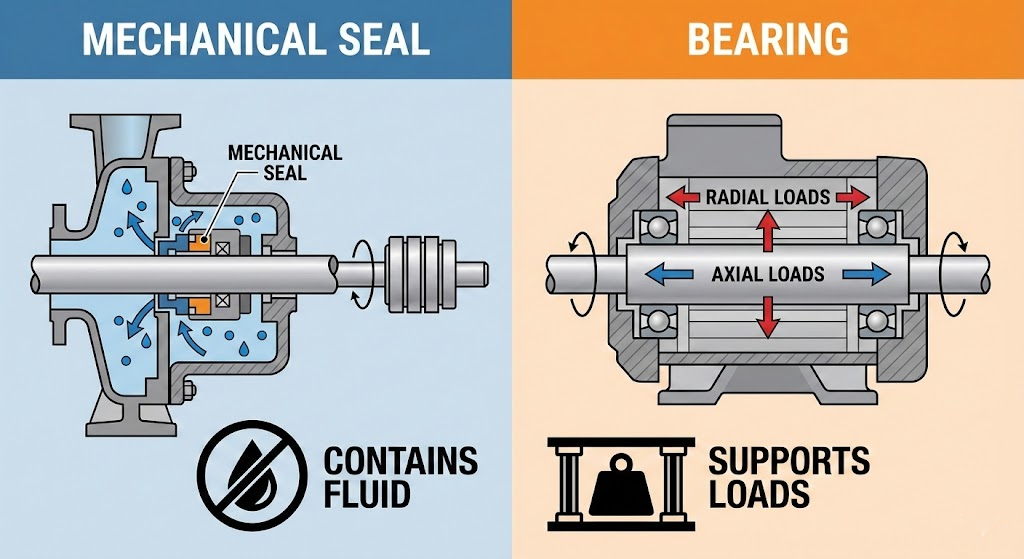

The short answer: Mechanical seals prevent fluid from leaking out where a rotating shaft meets a stationary housing. Bearings support the shaft and reduce friction so it can spin freely. You need both. One can’t replace the other.

What Is a Mechanical Seal and How Does It Work?

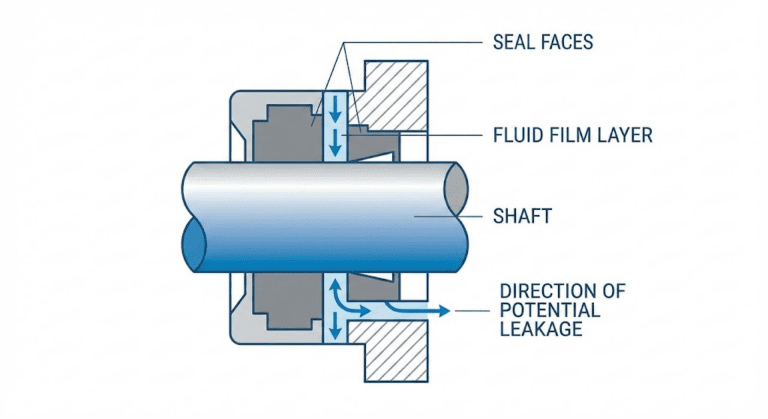

A mechanical seal is a precision device that stops fluid from escaping along a rotating shaft. You’ll find them in pumps, compressors, mixers, and any equipment where a spinning shaft passes through a stationary housing.

Think of it like pressing two extremely flat glass plates together underwater. The water can’t get between them because there’s no gap. That’s essentially what a mechanical seal does, except one surface spins while the other stays still.

What Are the Main Components of a Mechanical Seal?

Every mechanical seal has five core parts:

- Rotating face (primary ring) – This piece attaches to the shaft and spins with it. It’s made from hard, wear-resistant materials like carbon, ceramic, or tungsten carbide.

- Stationary face (mating ring) – This stays fixed to the pump housing and doesn’t move. It’s typically made from ceramic or silicon carbide.

- Springs or bellows – These push the two faces together, maintaining contact even when pressures and temperatures fluctuate.

- Secondary seals – O-rings and gaskets that seal the gaps around the primary components.

- Gland plate – The mounting bracket that holds the stationary face in position.

What Is a Bearing and How Does It Work?

A bearing is a machine component that supports rotating parts and reduces friction between them. Every electric motor, every wheel, every gearbox relies on bearings to function.

The basic principle is simple: rolling friction is much lower than sliding friction. Push a heavy box across the floor, and it takes serious effort. Put the same box on rollers, and a child can move it. Bearings apply this principle to rotating machinery.

What Are the Key Components of a Bearing?

Most rolling element bearings contain four parts:

- Inner race – A smooth ring that fits around the shaft and rotates with it.

- Outer race – A larger ring that sits in the housing and usually stays stationary.

- Rolling elements – Balls, cylindrical rollers, or needle rollers that sit between the races.

- Cage (retainer) – A separator that keeps the rolling elements evenly spaced so they don’t collide.

What Are the Key Differences Between Mechanical Seals and Bearings?

| Aspect | Mechanical Seal | Bearing |

|---|---|---|

| Primary Purpose | Prevent fluid leakage | Support loads and reduce friction |

| Location | Between rotating shaft and stationary housing | Between rotating shaft and its support structure |

| Operating Principle | Two flat faces with a thin fluid film barrier | Rolling elements convert sliding to rolling friction |

| Key Materials | Carbon, ceramic, tungsten carbide, silicon carbide | Chrome steel (SAE 52100), ceramic |

| Common Applications | Pumps, compressors, mixers | Motors, gearboxes, turbines, wheels |

| Maintenance Focus | Leakage prevention and face condition | Lubrication and load management |

The fundamental difference comes down to function: seals contain, bearings support. A bearing can’t stop fluid from leaking. A mechanical seal can’t hold a shaft in position or carry its weight.

How Do Seals and Bearings Work Together in Pumps?

In any pump, seals and bearings form a system. Problems with one component often damage the other.

I’ve actually heard this question from people new to rotating equipment. The answer is fundamental: bearings and seals solve completely different problems.

Bearings support the rotating shaft, keep it centered, and reduce friction so it can spin. They excel at handling loads and enabling rotation. But they have gaps, spaces for rolling elements and lubricant. Fluid would pour right through.

Mechanical seals create a barrier where the shaft passes through the pump housing. They prevent process fluid from escaping and keep atmospheric air or contaminants out. But they can’t support loads or reduce friction in the rotating assembly.

Every pump needs both. You can’t substitute one for the other any more than you could substitute a door for a window.