You’ve probably never thought much about the small components keeping fluid inside your equipment. But oil seals and mechanical seals are the difference between a functioning machine and a messy, broken one.

Here’s the real issue: picking the wrong seal type can cost you thousands in downtime, repairs, and wasted resources. If you’re managing rotating equipment—whether it’s a pump, motor, mixer, or compressor—you need to understand these two fundamental sealing solutions.

Oil seals and mechanical seals both prevent leakage, but they do it completely differently. One is simple and cheap but needs frequent replacement. The other is complex and expensive but can run for years without attention. This guide walks you through the key differences so you can make the right choice for your equipment.

What are Oil Seals and How Do They Work?

Understanding Oil Seals

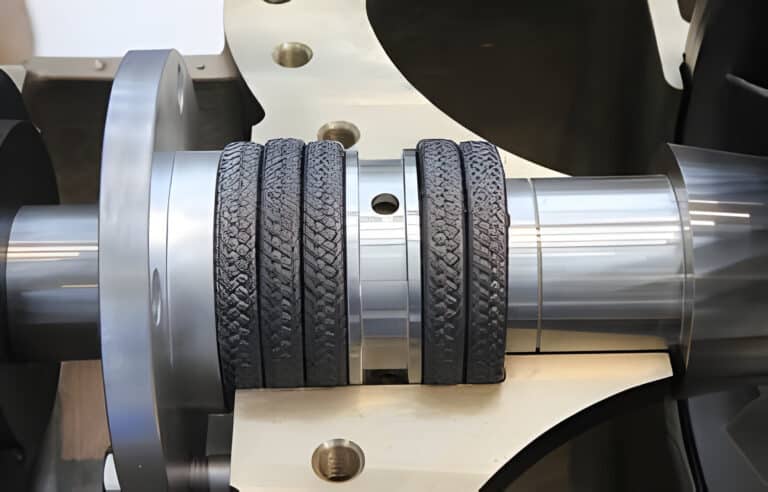

An oil seal is a rotary shaft seal that stops lubricant from leaking out of equipment and prevents dirt, water, and other contaminants from getting in. It’s one of the simplest and most common sealing solutions you’ll find in industrial equipment.

Think of an oil seal as a squeegee on a rotating shaft. A flexible rubber lip presses against the spinning shaft, creating a barrier that keeps fluid in and contamination out. Simple concept, but it works remarkably well for basic applications.

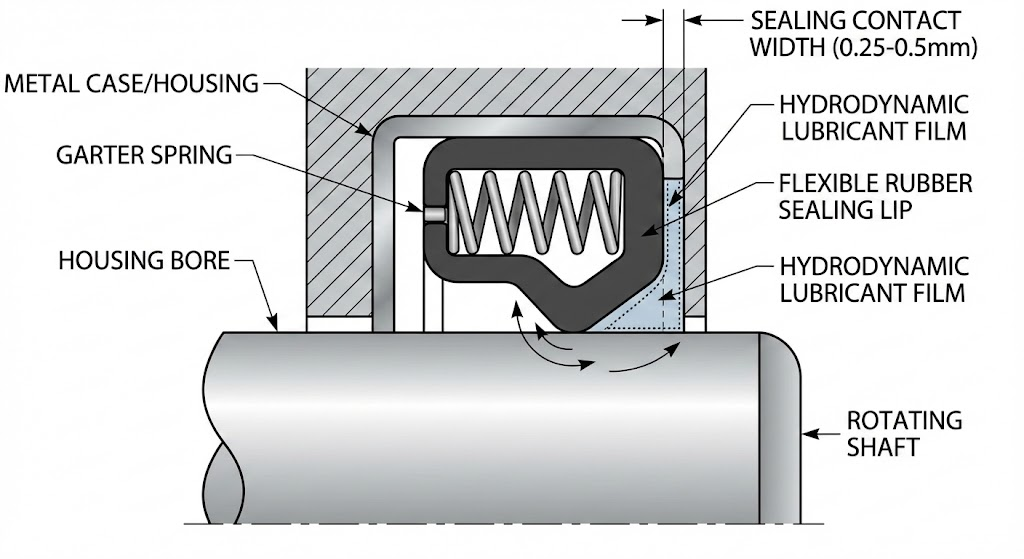

How Oil Seals Actually Work

The spinning shaft creates a hydrodynamic film of lubricant between the seal lip and the shaft surface. This film thickness depends on shaft speed, oil viscosity, temperature, and the pressure the seal lip exerts. The faster the shaft spins, the thicker the film—up to a point.

The rubber lip isn’t sitting flat against the shaft. It creates a sealing contact ring only 0.25 to 0.5mm wide. Within this tiny gap, the oil forms a meniscus (a curved surface) due to surface tension. This meniscus acts like an invisible dam, preventing oil from leaking while allowing just enough fluid to lubricate the seal.

The spring maintains interference—the rubber lip is slightly smaller than the shaft, creating pressure that keeps the seal effective. This interference pressure plus the spring force create the radial pressure needed for reliable sealing.

Think of it like this: the hydrodynamic action creates a wedge of oil, the rubber lip’s interference creates pressure, and surface tension does the final sealing. Together, they create a seal that works silently and reliably for years—until it doesn’t.

What are Mechanical Seals and How Do They Work?

Understanding Mechanical Seals

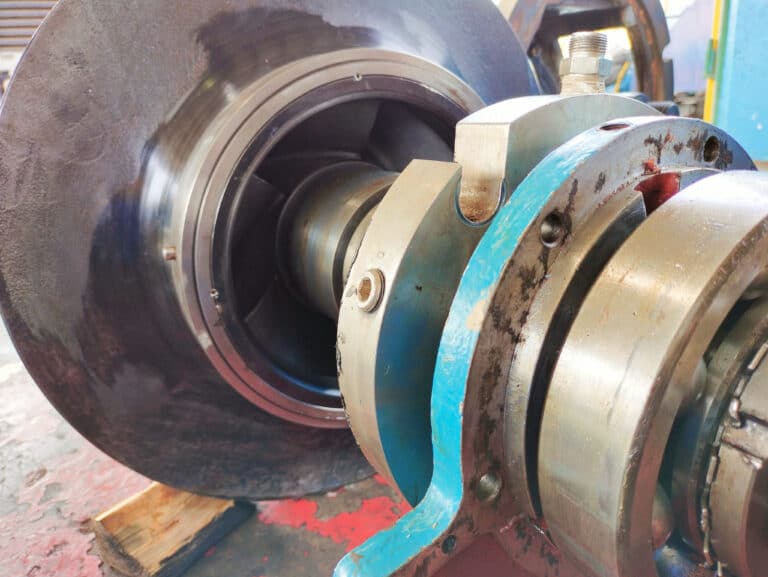

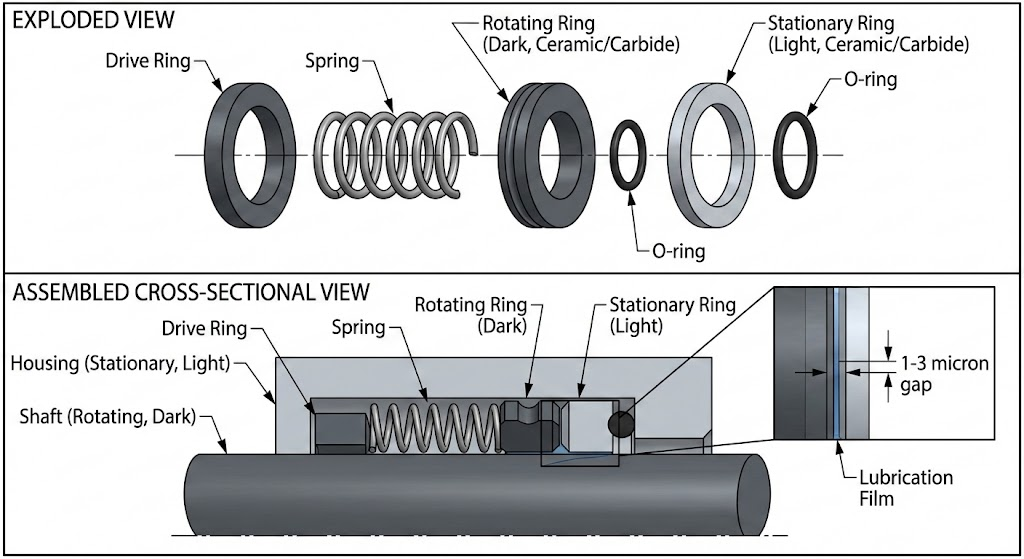

A mechanical seal is fundamentally different from an oil seal. Instead of a single flexible lip, a mechanical seal uses two precisely machined flat faces—one rotating with your shaft, one stationary on the housing—that run against each other to prevent leakage.

If an oil seal is a squeegee, a mechanical seal is more like two perfectly polished mirrors placed face-to-face. The seal works by maintaining an incredibly precise gap between these faces where a thin film of lubricant prevents them from touching directly.

This precision requirement is why mechanical seals handle extreme pressures, temperatures, and demanding applications that would destroy an oil seal in minutes.

How Mechanical Seals Work

The principle is elegant but the execution is demanding: two ultra-flat faces spinning against each other, separated by a film thinner than a human hair, prevent leakage of pressurized fluid.

When your equipment starts, the spring pushes the rotating ring forward until it contacts the stationary ring. The seal face gap is maintained at 1-3 microns—large enough to allow a thin film of clean lubricating liquid through, small enough to keep out contaminants.

As your equipment runs, the process fluid (or an external support fluid in some designs) enters this microscopic gap. The rotating action creates slight turbulence, forming a hydrodynamic wedge that supports the rotating ring on a thin cushion of fluid. This is critical: the seal isn’t actually metal-on-metal contact. It’s a fluid film separating the faces.

The spring constantly adjusts to maintain this gap. If the shaft moves slightly, the spring accommodates it. If thermal expansion occurs, the spring adjusts. This continuous adjustment is why mechanical seals can operate reliably in harsh conditions.

Key Differences Between Oil Seals and Mechanical Seals

Now that you understand how each seal works, let’s look at the practical differences that matter for your equipment selection.

Design Complexity

Oil seals are simple: one flexible lip, one metal case, one spring. They’re straightforward to manufacture and understand.

Mechanical seals are complex: multiple precision-ground components, exact tolerances, careful assembly. A single mechanical seal contains more engineering per square inch than many complete devices.

Simple means cheaper to make and easier to replace. Complex means better performance but higher skill requirements for installation and maintenance.

Pressure Handling

Oil seals are designed for low-pressure applications—typically no more than 8 psi (55 kPa). Try to push them beyond this, and the seal lip will deflect, creating pathways for leakage. In many applications, you need pressure relief if internal pressure exceeds this limit.

Mechanical seals laugh at 8 psi. They’re engineered to handle up to 6900 kPag (1000 psig) and beyond. Some high-end mechanical seals can handle even higher pressures in specialized applications.

Sealing Mechanism and Performance

Oil seals create a single contact line—the rubber lip pressing against the shaft. Leakage occurs if this contact line is compromised by wear, misalignment, or contamination.

Mechanical seals create two contact surfaces—the rotating and stationary face interface. This provides multiple fail-safes. If one component has minor contamination, the seal often still works.

Oil seals typically allow slight, controlled leakage. Some seepage is normal and expected—it helps cool and lubricate the seal. This is fine for many applications but unacceptable when you’re sealing hazardous chemicals or trying to prevent environmental contamination.

Mechanical seals can operate virtually dry—near-zero leakage. This is why they’re required in petrochemical facilities, pharmaceutical plants, and wastewater treatment where environmental regulations demand minimal losses.

Lifespan and Durability

Oil seal lifespan varies widely depending on operating conditions, but plan on replacement every 1-5 years in typical applications. In harsh environments (high speed, high temperature), you might replace them annually.

Mechanical seals, when properly installed and maintained, typically last 18 months to 3 years under normal operating conditions. Some well-designed seals in ideal applications run 5+ years.

Here’s the real kicker: while mechanical seals might need replacement at similar intervals, they require zero maintenance between replacements. Oil seals degrade continuously and often start leaking months before complete failure.

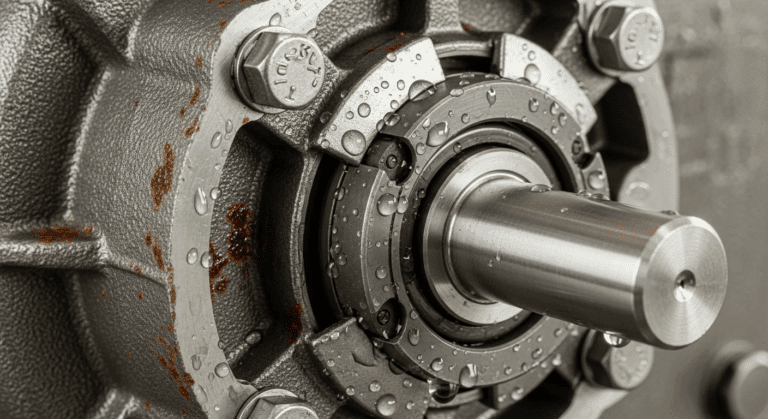

Installation and Maintenance Requirements

Installing an oil seal? Anyone with basic mechanical skills can do it. Push it into the bore, align it with the shaft, and you’re done. Ten-minute job.

Installing a mechanical seal? This demands precision and expertise. You must ensure perfect axial and radial alignment. Even fingerprints on the seal faces can cause failure. Professional installation is strongly recommended. Specialized tools make the job easier but require training.

Maintenance also differs. Oil seals need periodic inspection for wear and replacement before they completely fail. You’re managing an aging component.

Mechanical seals demand cleanliness and system integrity. You monitor operating parameters (temperature, pressure, vibration, leakage) and verify the support fluid or barrier fluid is clean and at the correct pressure. More monitoring, but less hands-on maintenance.

Cost Considerations

Let’s talk money.

An oil seal costs $10-50 depending on size and materials. You can buy dozens of them for what one mechanical seal costs.

A mechanical seal costs $100-500+ for industrial-grade seals, plus installation labor and specialized tools. The installed cost for a complete mechanical seal assembly can exceed $1000.

When to Use Oil Seals vs. Mechanical Seals

Best Applications for Oil Seals

Oil seals excel in automotive applications—engine crankshaft seals, transmission seals, differential seals. These are low-pressure, moderate-temperature environments perfect for oil seals.

General machinery uses oil seals extensively: gear boxes, electric motor bearings, hydraulic cylinders, vacuum pump housings. Any equipment where simplicity and cost matter more than zero leakage.

Budget-conscious applications favor oil seals. If you’re sealing lubricant in an industrial bearing box and environmental regulations aren’t a concern, an oil seal is economical and proven.

Older or legacy equipment might be designed around oil seals. Retrofitting a new seal type often isn’t practical.

Best Applications for Mechanical Seals

Industrial pumps almost universally use mechanical seals. Centrifugal pumps, positive displacement pumps, and submersible pumps—they all rely on mechanical seals for safe, reliable operation.

Mixers and agitators in chemical plants use mechanical seals to prevent hazardous fluid leakage into the environment.

Oil and gas industry uses mechanical seals extensively in wellhead equipment, compression systems, and transfer pumps—often in extreme pressure and temperature conditions.

Wastewater treatment plants mandate mechanical seals to prevent environmental contamination.

Pharmaceutical manufacturing requires mechanical seals for sterile processing where contamination could ruin expensive batches.

Any application pumping hazardous, toxic, or flammable fluids demands mechanical seals.

Selection Criteria

Ask these questions to guide your choice:

What pressure will the seal face? If above 8 psi, choose mechanical. Below 8 psi, either works, but mechanical is safer.

What temperature range? For -40°C to +120°C, either type works. For higher temperatures, check material compatibility. FKM oil seals handle up to 180°C; NBR tops out around 120°C. Mechanical seals with ceramic faces handle much higher temperatures.

What’s the shaft speed? High-speed equipment benefits from mechanical seals. Oil seal lip wear increases dramatically at high speeds.

What fluid are you sealing? Is it compatible with your seal material? NBR rubber works with petroleum oils but not all synthetics. Check compatibility carefully.

What are your maintenance resources? Can you support frequent oil seal replacement and monitoring, or do you prefer set-it-and-forget-it mechanical seals?

What’s your budget for initial installation versus lifetime maintenance? Oil seals win initially; mechanical seals often win long-term.

Conclusion

Oil seals and mechanical seals serve fundamentally different purposes. Oil seals are simple, economical solutions for low-pressure applications where simplicity and cost matter most. Mechanical seals are precision engineering for high-pressure, high-consequence applications where reliability and environmental protection are paramount.

The choice isn’t about which is “better”—they excel in different situations. An oil seal is completely adequate (and more economical) in a motor bearing. A mechanical seal is essential in a petrochemical pump.

Understand your application. Know your pressure, temperature, fluid type, and regulatory requirements. Match these requirements to the seal type designed for them. When you choose correctly, you get reliable equipment that runs efficiently for years.