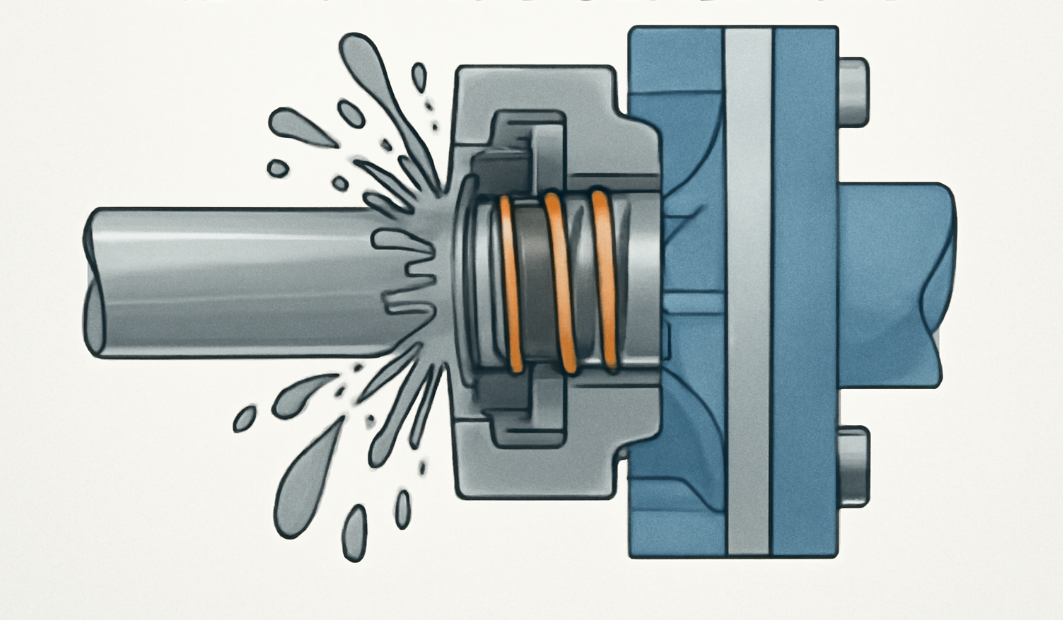

“If your pump has a worn shaft, chronic misalignment problems, bearing wear, or vibration issues, installing a mechanical seal will likely fail.” This reality check matters because mechanical seals demand equipment precision that gland packing simply tolerates.

Retrofitting from packing to mechanical seals can slash maintenance intervals from months to years and eliminate the controlled leakage that packing requires. But successful retrofit depends on whether your pump meets specific dimensional and mechanical criteria. The most common mistake I see is facilities rushing into retrofit without evaluating these requirements first – then discovering mid-project that the pump was never a good candidate.

This guide provides a systematic framework to evaluate retrofit feasibility before you commit resources or disassemble equipment.

Is Retrofit Feasible for Your Pump?

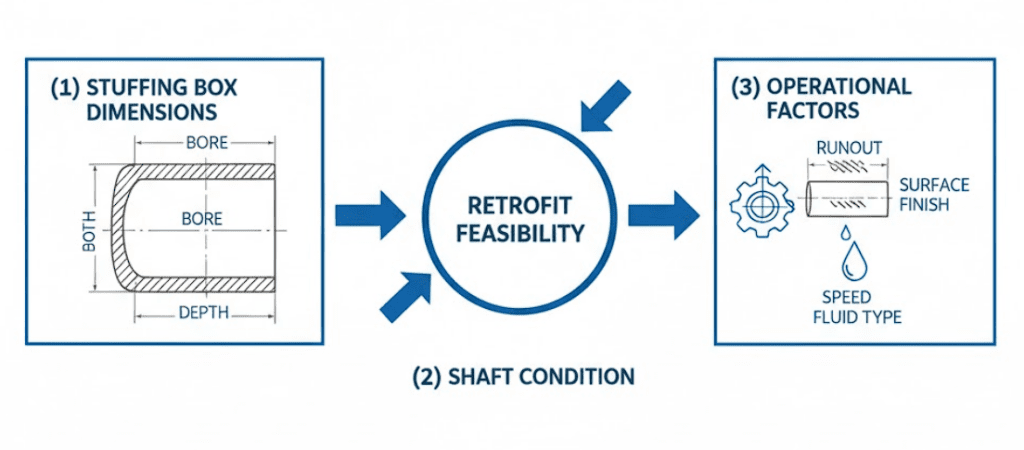

Retrofit feasibility comes down to three evaluation categories: stuffing box dimensions, shaft condition, and operational compatibility.

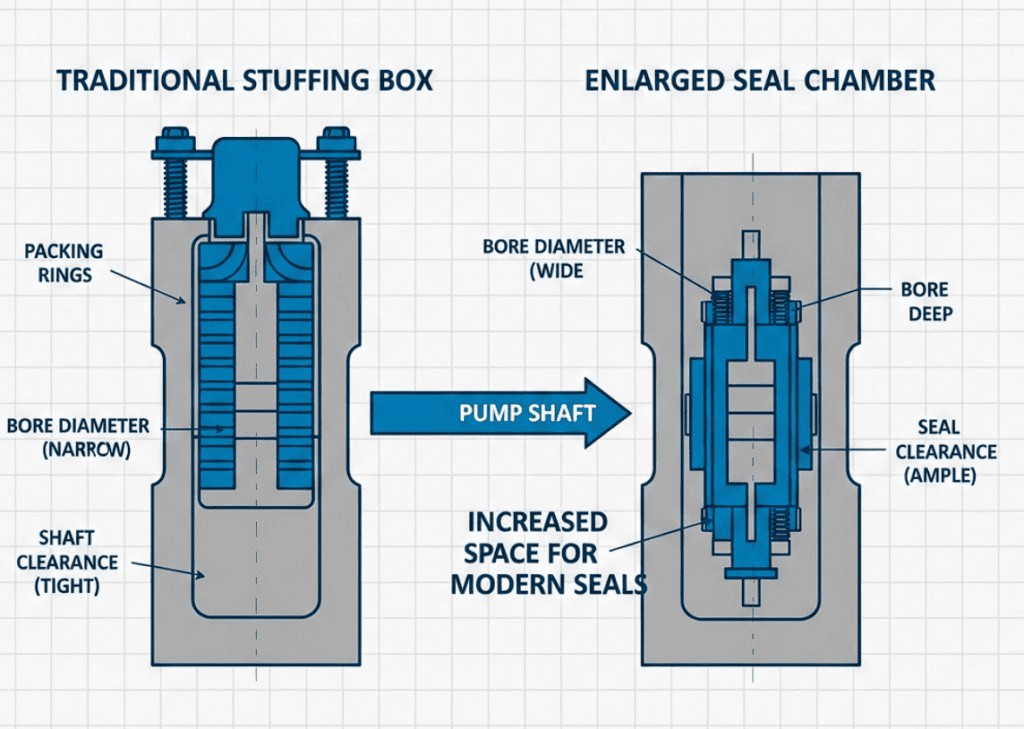

Dimensional requirements determine whether a mechanical seal will physically fit. Original stuffing boxes designed for packing often lack the space mechanical seals need for proper heat dissipation and fluid circulation.

Shaft condition must meet tight tolerances. Mechanical seals require shaft runout, radial movement, and surface finish specifications that packing never demanded. If your current shaft shows wear from years of packing contact, that damage affects seal compatibility.

Operational factors include pump speed, process fluid characteristics, and maintenance access. High-speed pumps and certain pump designs create additional constraints.

Before proceeding, make sure the pump is in good mechanical condition. Retrofit cannot fix existing problems – it will expose them. Shaft deflection, bearing wear, and alignment issues that packing accommodated will cause rapid seal failure. For background on how these sealing methods differ, see the gland packing vs mechanical seal comparison.

Stuffing Box Dimensional Requirements

The original stuffing box may not provide adequate space for a mechanical seal. Pump manufacturers designed early stuffing boxes as the lowest-cost option for packing installation. Later, enlarged seal chambers were developed specifically for mechanical seals because the tight confines of a stuffing box do not allow enough liquid circulation around the seal to remove sufficient heat or keep solids away from seal faces.

Measuring for Fit

Critical measurements before retrofit:

| Parameter | Specification |

|---|---|

| Concentricity | Within 0.001 inch per inch shaft diameter, max 0.005 inch TIR |

| Seal chamber squareness | Within 0.0005 inch per inch bore |

| Stuffing box bore | Must accommodate seal OD plus clearance |

| Stuffing box depth | Must accommodate seal length plus gland |

The concentricity and squareness requirements matter because any misalignment causes uneven loading on seal faces, leading to premature wear and leakage. If measuring your stuffing box reveals dimensions outside these tolerances, you’ll need to machine the housing or select a seal designed for tighter spaces.

Pre-1995 Pump Compatibility

Pumps manufactured before API 610 Seventh Edition (1995) present special challenges. For older pumps, seal chambers may be smaller and there are no standard dimensions. In many cases, API 682 products can be engineered to fit, but usually exceptions are required. In some cases, it will not be possible to fit API 682 products into older pumps at all.

This age-based compatibility issue catches many facilities by surprise. If your pumps predate the mid-1990s, expect custom seal engineering or stuffing box modification. Both add cost and lead time to the project.

Shaft Condition Criteria

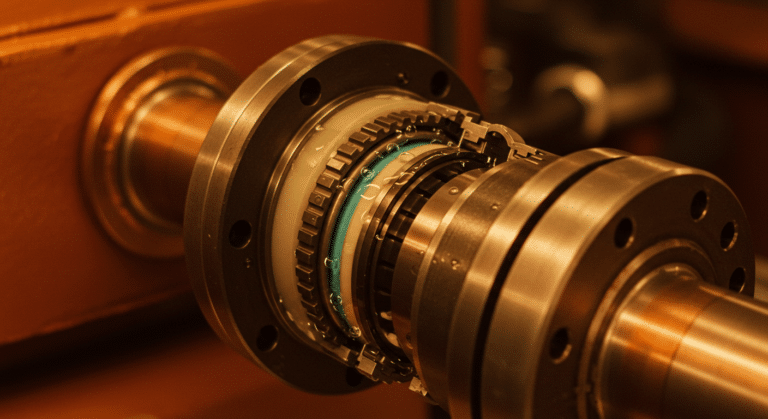

Mechanical seals are precision devices. The shaft must meet six parameters for the seal to function properly – and one failure point can doom the entire retrofit.

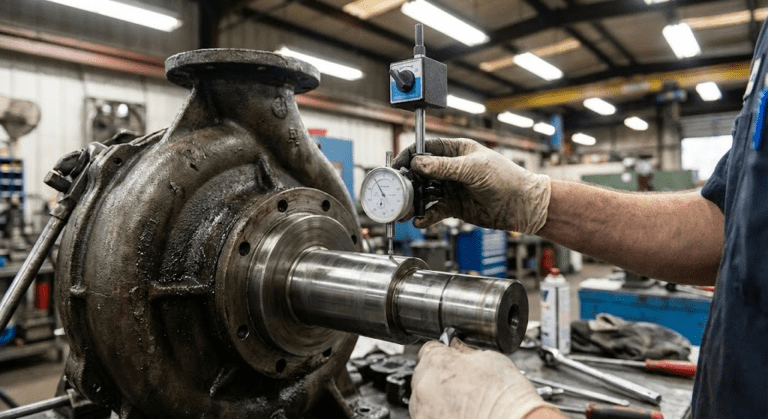

Shaft runout is the most common disqualifier. Most mechanical seals require runout below 0.005 inches (0.13 mm) TIR. For high-speed equipment above 3,600 RPM, tighter tolerances of 0.001-0.002 inches are required. Excessive runout causes seal faces to separate with each shaft rotation, resulting in immediate leakage.

Radial shaft movement must stay within 0.002-0.004 inches for pumps with ball or roller bearings. This is the allowable lateral movement during operation, not static runout.

Axial displacement should be less than 0.5 mm. The springs in mechanical seals cannot compensate for excessive shaft endplay.

Shaft endplay (axial movement from thrust bearing clearance) should not exceed 0.010 inch TIR regardless of bearing type.

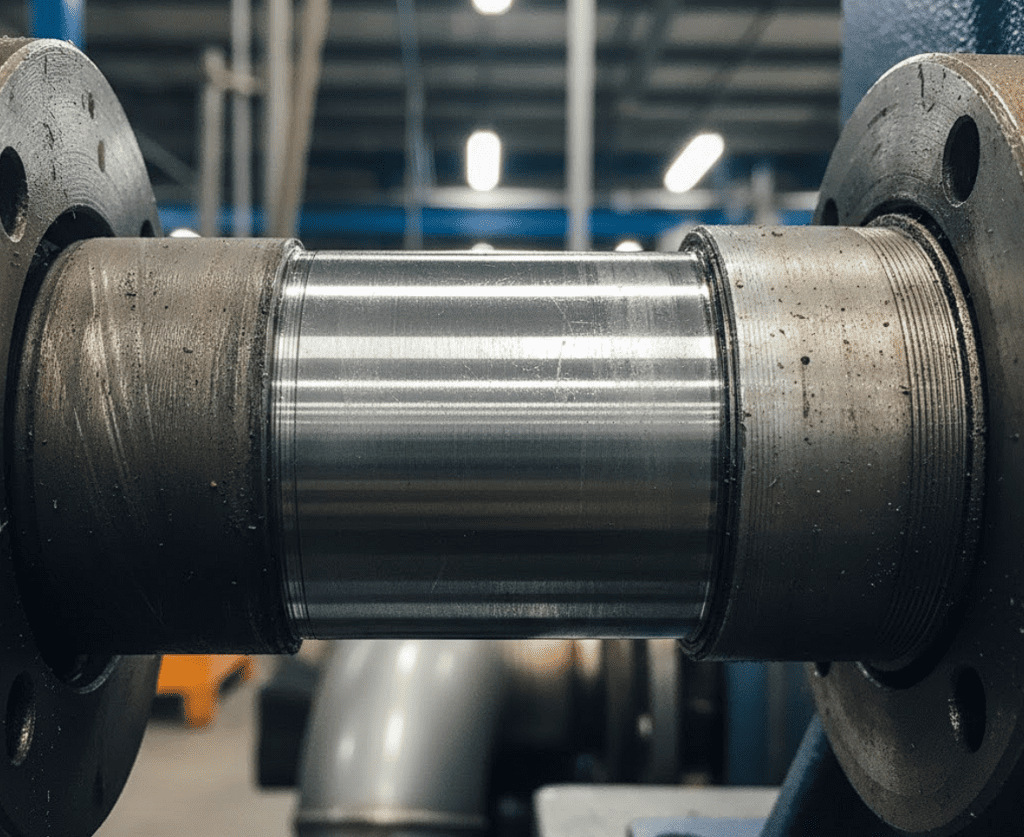

Surface finish on the shaft sleeve area requires 0.4 to 0.8 micrometers Ra (16 to 32 microinches). Some precision applications need 0.2 micrometers Ra or better. Shafts worn from packing contact rarely meet these specifications without rework.

Seal preload must match manufacturer specifications – this is set during installation but requires that all other parameters already meet spec.

This is where I recommend cartridge mechanical seals over component seals for retrofit applications. Cartridge seals arrive as preassembled units with preset spring tension. They mount on a new sleeve surface away from packing-worn areas of the shaft. Component seals, while less expensive, require precise assembly on potentially damaged shaft surfaces.

When Retrofit Won’t Work

Some pumps are not candidates for retrofit. Identifying these scenarios early saves money and frustration.

Severe shaft damage from packing wear. If the shaft is grooved or scored beyond surface finish correction, component seals cannot seal properly. Cartridge seals may still work if a new sleeve can be installed, but evaluate whether the cost makes sense compared to pump replacement.

Inadequate stuffing box depth or bore. When the existing housing cannot be modified and the smallest available seal still won’t fit, retrofit becomes impractical.

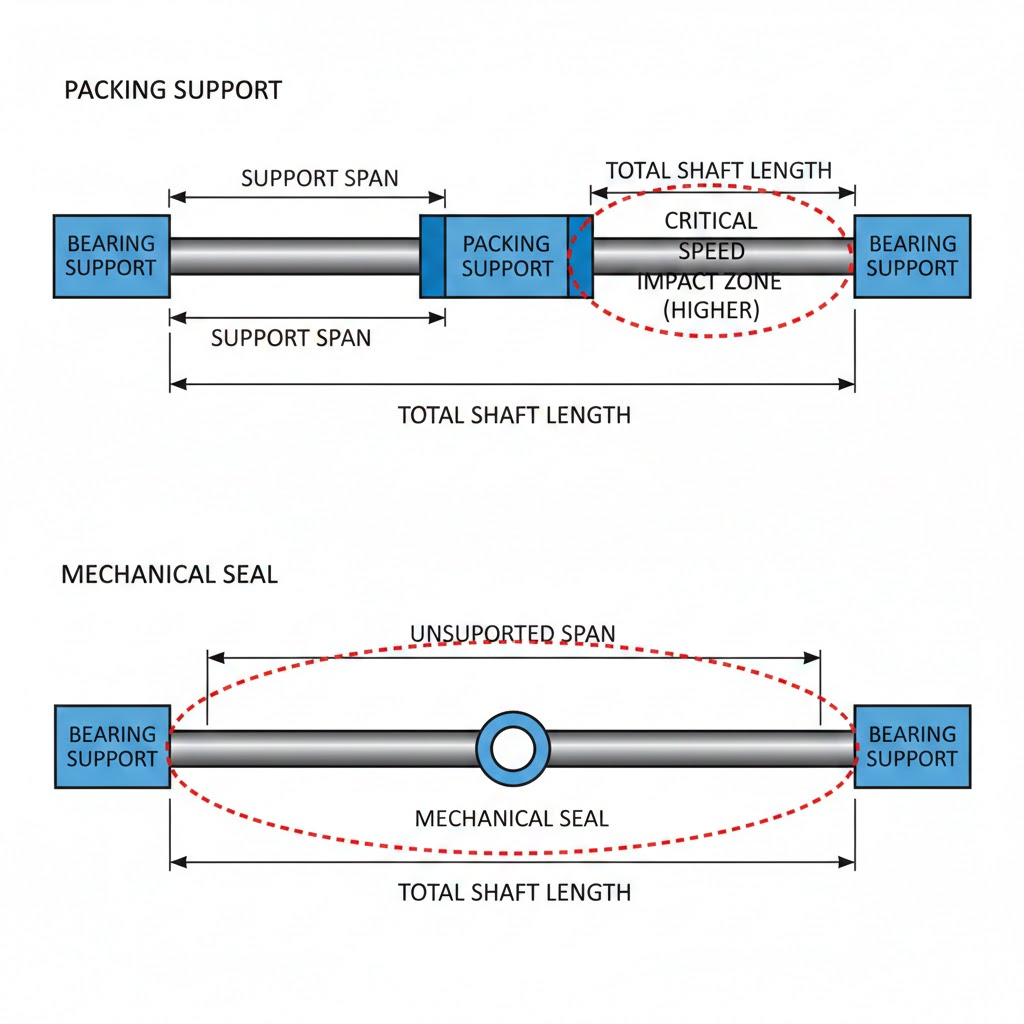

Critical speed concerns on legacy equipment. Converting from packing to mechanical seals removes the rotor support that packing provided. As one rotating equipment engineer noted: “Converting to seals will have less support than packing, so it will have a longer span between supports. This lowers the first critical speed and will bring it closer to the operating range.”

For emergency standby pumps or older equipment running near critical speed, this dynamic change may create vibration problems that didn’t exist with packing.

Abrasive or high-solids service where the process fluid will destroy seal faces quickly. Packing tolerates contaminated fluids that mechanical seals cannot handle without expensive flush systems.

Pumps requiring frequent disassembly for other reasons. If the pump design requires removing the bearing bracket for every seal change, retrofit may increase rather than decrease maintenance burden.

The honest assessment: not every pump should be retrofitted. Some are better served by continued packing operation or full pump replacement.

Making the Decision

Before contacting seal suppliers for quotes, gather these measurements from your pump:

- Stuffing box bore diameter and depth

- Shaft diameter at seal location

- Shaft runout (measured with dial indicator)

- Distance from stuffing box face to impeller

- Pump speed (RPM)

- Process fluid and temperature

This information lets suppliers assess feasibility and recommend appropriate seal types. Missing any of these measurements will delay the process.

For facilities new to mechanical seal retrofit, start with a pilot approach. Convert a few pumps first to learn what works before full deployment. This incremental method reveals site-specific issues – shaft condition patterns, installation training needs, flush system requirements – that would otherwise create problems across a larger conversion project.

The goal of feasibility evaluation is a clear go or no-go decision for each pump. Systematic evaluation prevents the costly scenario of discovering mid-retrofit that the pump was never suitable. When you know the criteria upfront, you can focus resources on pumps that will actually benefit from the upgrade to mechanical seals.