A faulty well pump pressure switch can disrupt water supply systems, causing a range of operational issues. These issues manifest as complete lack of water pressure, low water flow, or inconsistent operation, affecting both residential and commercial settings.

This guide will cover how to identify the symptoms of a failing pressure switch, providing step-by-step instructions for DIY repair, along with a cost comparison between DIY and professional help.

Identifying the Symptoms of a Bad Pressure Switch

Several key symptoms indicate a problem with the pressure switch. Here are the most common:

A. Complete Lack of Water Pressure

One of the most apparent signs of a failing pressure switch is a complete lack of water pressure. If the pump fails to activate, no water will flow into the home. This usually occurs when the pressure switch does not detect a drop in water pressure, failing to send the signal to the pump to turn on.

B. Low Water Pressure

If the water pressure is consistently weak, even when the pump is running, it could point to a failing pressure switch. This happens when the switch isn’t properly signaling the pump to run at its full capacity or to maintain a specified pressure. A worn-out switch may struggle to make consistent contact.

C. The Pump Fails to Turn On

If the pump does not start when the water pressure is low, it’s likely a problem with the pressure switch. This may indicate that the switch is not sensing the pressure drop, which should activate the pump. The contacts within the switch may be faulty or corroded preventing it from working as intended.

D. The Pump Fails to Turn Off

Conversely, if the pump continues to run even when the water pressure is high, the pressure switch may be failing. The switch should turn off the pump when the system reaches the upper pressure limit. If it doesn’t, it may be stuck in the ‘on’ position, leading to continuous pump operation. This can cause pump damage and increased electricity consumption.

E. Rapid Pump Cycling (Short Cycling)

Rapid pump cycling, also known as short cycling, is when the pump turns on and off frequently. This happens when the pressure switch is not correctly sensing the pressure, causing the pump to cycle rapidly to maintain water pressure in the system. This frequent starting and stopping of the pump can lead to premature pump failure.

F. Fluctuating Water Pressure

Inconsistent water pressure that alternates between high and low could point to an issue with the pressure switch. A faulty switch may not maintain a consistent pressure level, leading to pressure fluctuations. These can be irritating and may affect the proper functioning of water-using appliances.

G. Unusual Pump Noises

Grinding, squealing, or humming noises coming from the pump can be an indication that the pressure switch is malfunctioning. These noises often accompany the pump’s attempts to start and stop erratically due to a faulty switch, or may result from the pump running continuously.

H. Audible Clicking near the Pressure Tank

If a clicking sound is heard near the pressure tank, it could be the pressure switch attempting to engage. This noise can signal that the switch is struggling to establish or break contact, indicative of a failing component.

Troubleshooting & DIY Repair: A Step-by-Step Guide

Step 1: Safety First

Before beginning any troubleshooting or repair work, turn off the power to the well pump at the circuit breaker. Then, drain the pressure tank to release any water pressure in the system.

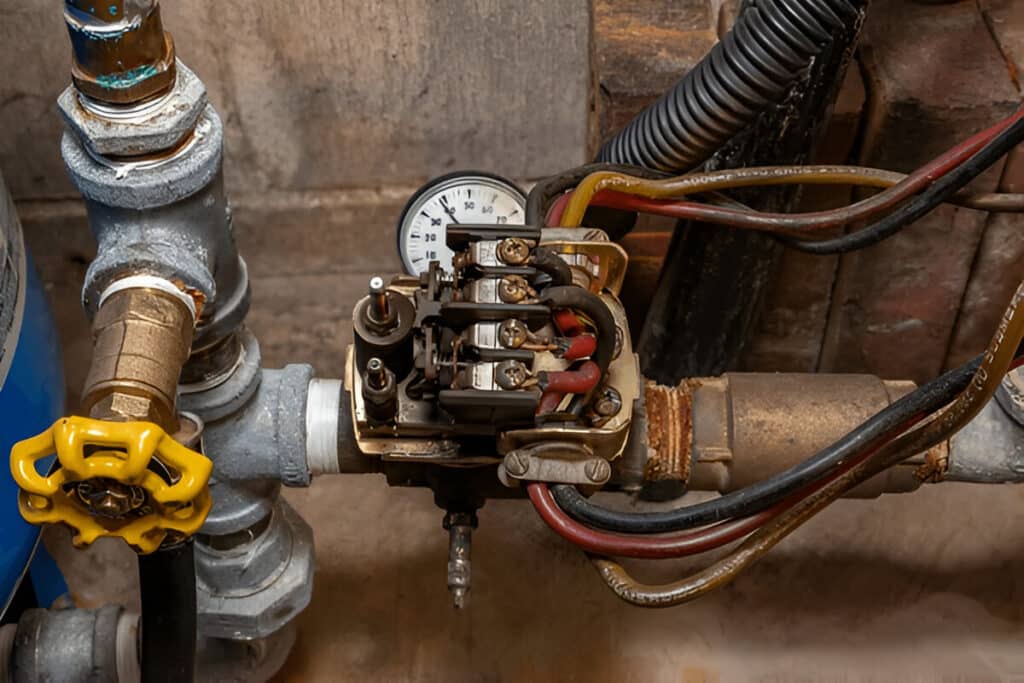

Step 2: Inspect the Pressure Switch

Locate the pressure switch, usually mounted on or near the pressure tank. Check the switch for signs of physical damage, such as cracks, loose wires, or corrosion. Look closely at the electrical contacts inside the switch; they should be clean and free of corrosion.

Step 3: Clean the Switch Contacts

If the contacts are corroded, carefully clean them with a wire brush or sandpaper. Ensure you have disconnected the power before doing this. After cleaning, check the wires connected to the pressure switch to ensure they are secure and in good condition.

Step 4: Test the Switch

Use a multimeter to test the continuity of the pressure switch. With the system depressurized, check for continuity between the pressure switch terminals to ensure the switch is working. When the tank is pressurized and the pump should be off, check to see if the continuity is broken. If the switch fails the tests, it will likely need replacing.

Step 5: Replace the Pressure Switch

If the pressure switch is confirmed to be faulty, replace it with a new one of the same specification. Carefully disconnect the wires from the old switch, and connect them to the new switch, ensuring a secure connection. Then, install the new switch by screwing it into the pressure tank or the designated location on the pump line.

Step 6: Restore Power and Check Operation

After replacing the switch, turn the power back on to the well pump and watch the system as it pressurizes. The pump should activate when pressure drops and turn off once the cut-out pressure has been reached. Keep checking the system for leaks and correct operation.

Cost of Repair Vs. Replacement

Here is an overview of the costs associated with repairing or replacing a well pump pressure switch:

- DIY Switch Replacement (Parts): The cost of a new pressure switch typically ranges from $20 to $70, depending on the brand and specifications. This option is suitable for those comfortable working with electrical components and plumbing.

- Professional Switch Replacement (Parts & Labor): Hiring a professional plumber to replace the pressure switch can cost between $150 and $400. This covers both the cost of the switch and the plumber’s labor charges.

- Professional Diagnostic and Repair Costs: If you are unsure about the cause of the problem, a professional may charge $50 to $150 for diagnostics. If the repair is more extensive than just replacing the switch, the total cost could be higher, depending on the complexity of the repair.