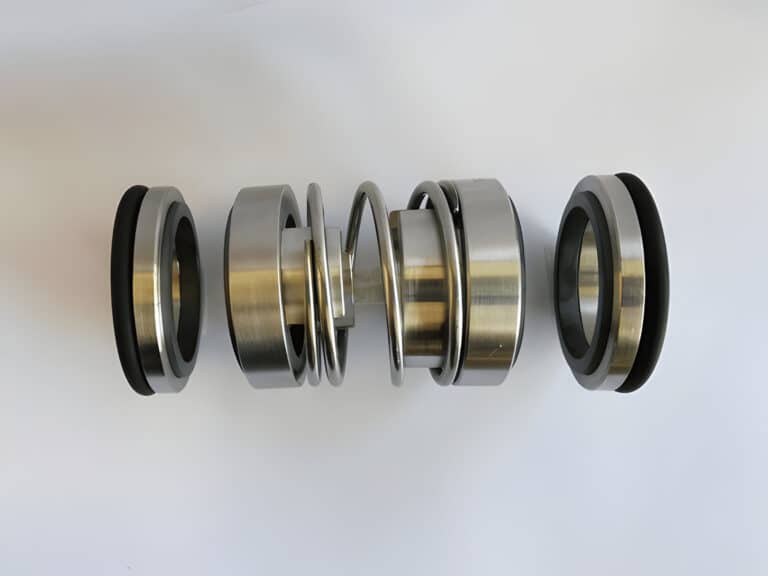

Your pump’s mechanical seal is working right now, silently holding back pressurized fluid and keeping contaminants out. But here’s what most maintenance teams don’t realize: choosing the wrong seal material can cost you thousands in unexpected downtime.

Silicon carbide and tungsten carbide represent the two premium options for mechanical seal faces. Each performs brilliantly in different conditions, but they’re engineered for completely different jobs. Understanding which material matches your equipment will help you avoid costly failures, extend service life, and keep your operation running smoothly.

This guide breaks down the key differences, helps you understand why material selection matters, and gives you a clear framework for choosing the right seal for your specific application.

Silicon Carbide Mechanical Seals: Properties and Performance

What Are the Key Properties of Silicon Carbide?

Silicon carbide is a ceramic composite material created by fusing silica and coke at extremely high temperatures. This manufacturing process produces a material that’s almost as hard as diamond.

Here’s what that hardness means for your seal:

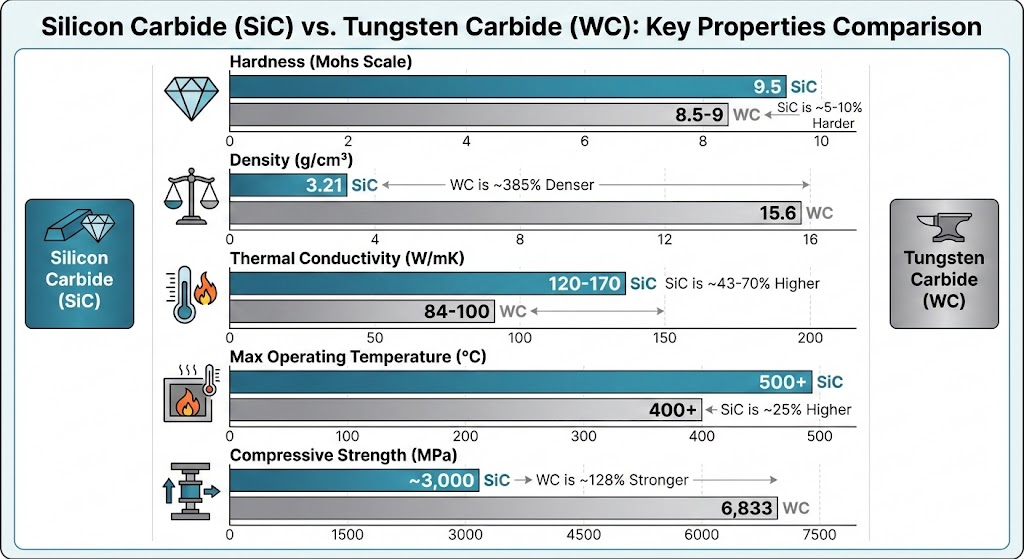

- Mohs Hardness: 9.5 (extremely hard)

- Vickers Hardness: 2500-2800 HV (nearly identical to diamond)

- Density: 3.21 g/cm³ (relatively light)

- Thermal Conductivity: 120-170 W/mK (excellent heat dissipation)

- Thermal Expansion Coefficient: 4.0-4.5 x 10⁻⁶/°C (minimal size change with temperature)

- Maximum Operating Temperature: 500°C and beyond

That combination of extreme hardness and excellent thermal conductivity makes silicon carbide uniquely suited to demanding applications.

Where Does Silicon Carbide Excel?

Silicon carbide dominates in three critical scenarios: high-temperature operations, corrosive environments, and abrasive applications.

In high-temperature service, silicon carbide’s superior thermal conductivity pulls heat away from the seal faces faster than other materials. This prevents the thermal damage that destroys seals. The material’s low thermal expansion coefficient means it doesn’t change size dramatically with temperature swings, so you avoid the face separation that causes leaks during thermal cycling.

In corrosive environments, silicon carbide is chemically inert. It resists attack from strong acids, bases, solvents, and aggressive chemicals. While tungsten carbide can suffer oxidation and corrosion under harsh conditions, silicon carbide simply doesn’t degrade the same way.

In abrasive applications, the extreme hardness means less wear. Even when solid particles get trapped between the seal faces, silicon carbide resists scoring better than softer materials. This extends seal life significantly in slurry applications and contaminated environments.

Tungsten Carbide Mechanical Seals: Properties and Performance

What Are the Key Properties of Tungsten Carbide?

Tungsten carbide is a composite material created by sintering tungsten carbide particles with a cobalt binder. The result is an extremely dense, rigid material that resists deformation under extreme loads.

Here’s the technical profile:

- Mohs Hardness: 8.5-9 (very hard, but slightly less than SiC)

- Vickers Hardness: Around 2600 HV (comparable to SiC)

- Density: 15.6 g/cm³ (nearly five times heavier than SiC)

- Thermal Conductivity: 84-100 W/mK (good but lower than SiC)

- Thermal Expansion Coefficient: 5.0-6.0 x 10⁻⁶/°C (more size change with temperature)

- Compressive Strength: Up to 6,833 MPa (exceptional rigidity)

That density and compressive strength create a material that refuses to bend or distort under extreme pressure.

Where Does Tungsten Carbide Shine?

Tungsten carbide excels in three specific scenarios: extreme-pressure applications, high-vibration environments, and cost-sensitive operations.

Under extreme pressure, tungsten carbide’s rigid structure minimizes seal face distortion. When you’re running pressures that would deform other materials, tungsten carbide stays flat and maintains proper contact. This matters in high-pressure boiler feed pumps, hydraulic systems pushing over 3,000 psi, and charge pumps in refinery operations.

In vibration-prone environments, tungsten carbide outperforms silicon carbide. The material’s superior fracture toughness (it’s less brittle) means it survives shock loads and impact without cracking. Mining equipment, drilling rigs, and heavy industrial machinery favor tungsten carbide for this reason.

From a cost perspective, tungsten carbide has a lower upfront price than silicon carbide. For budget-conscious operations where extreme performance isn’t critical, this cost difference matters.

Direct Comparison: Silicon Carbide vs. Tungsten Carbide

Hardness and Wear Resistance

Both materials are extremely hard, but they approach hardness differently.

Silicon carbide’s 9.5 Mohs hardness edges out tungsten carbide’s 8.5-9. That small difference matters tremendously in wear applications. Over thousands of hours of operation, the superior hardness of silicon carbide produces noticeably lower wear rates.

In lab testing, silicon carbide typically shows 30-50% less wear than tungsten carbide in continuous-duty applications. This translates directly to longer seal life and fewer replacement cycles.

Where tungsten carbide wins is under impact. When solid particles slam into the seal faces or vibration introduces sudden stresses, tungsten carbide’s greater toughness resists fracture better. Silicon carbide, being harder but more brittle, can develop microscopic cracks that grow into failure.

The Wear Winner: Silicon carbide for continuous operation; tungsten carbide for shock and impact.

Temperature Performance

Temperature is where these materials show the starkest differences.

Silicon carbide’s superior thermal conductivity (120-170 W/mK versus 84-100 W/mK) means it pulls heat away from the seal faces far more efficiently. Even under identical operating conditions, a silicon carbide seal runs cooler than tungsten carbide.

That thermal efficiency matters enormously because seal life drops dramatically with temperature. Every 10°C reduction in seal face temperature can double service life. Silicon carbide’s superior heat dissipation provides that advantage automatically.

The thermal expansion differences reinforce this advantage. Silicon carbide expands less with temperature (4.0-4.5 x 10⁻⁶/°C versus 5.0-6.0 x 10⁻⁶/°C). This means less distortion of seal faces during thermal cycling. In batch processes with frequent startups and shutdowns, this prevents the face separation that causes sudden leaks.

Silicon carbide handles temperatures exceeding 500°C continuously, while tungsten carbide typically maxes out around 400°C before degradation becomes significant.

Chemical Resistance

Silicon carbide is chemically inert. Its covalent bonding structure makes it extremely resistant to acid attack, base attack, solvents, and oxidation. You can pump almost any industrial chemical through a silicon carbide seal without degradation.

Tungsten carbide is more vulnerable. The cobalt binder can dissolve in strong acids or bases. Oxidation at high temperatures can compromise the material’s integrity. In aggressive chemical environments, tungsten carbide seals often fail months ahead of silicon carbide seals in identical conditions.

If you’re sealing corrosive fluids—strong acids in chemical plants, alkaline process fluids in manufacturing, aggressive solvents in refineries—silicon carbide is the clear choice.

Pressure Resistance and Strength

Here tungsten carbide claims a genuine advantage.

Tungsten carbide’s compressive strength reaches 6,833 MPa, combined with its five-times-higher density, makes it the pressure champion. When you’re facing static pressures above 3,000 psi or dynamic pressure spikes that would deflect other materials, tungsten carbide’s rigidity is invaluable.

In boiler feed pumps pushing extreme pressures, tungsten carbide seals maintain perfect flatness while silicon carbide faces might deflect slightly. That small deflection allows micro-leakage to develop.

Tungsten carbide also survives vibration-induced impact better. While silicon carbide is harder, it’s also more brittle. Repeated shock loads can initiate microscopic cracks that eventually propagate into failure. Tungsten carbide’s superior fracture toughness makes it the better choice for equipment that vibrates.

The Pressure Winner: Tungsten carbide, clearly.

Cost Considerations

The pricing picture is more complex than “one is cheaper.”

Tungsten carbide typically has a lower initial purchase price—often 30-40% less than silicon carbide equivalents. For budget-conscious operations or commodity applications where margins are tight, this upfront savings is real.

But the total cost of ownership often tells a different story.

Silicon carbide’s longer service life (often 2-3 times longer) means fewer replacement cycles. Factor in labor costs for seal changes, equipment downtime, lost production, and emergency repair fees, and silicon carbide’s premium price frequently disappears when you do the math.

In critical applications where downtime costs are high—pharmaceutical manufacturing, continuous chemical plants, utility power generation—silicon carbide typically wins on total cost of ownership despite the higher initial expense.

In routine industrial operations with modest downtime costs, tungsten carbide’s lower initial price and adequate performance often make it the smarter choice.

How to Select the Right Mechanical Seal Material

What Factors Should You Consider?

Choosing the right seal material requires systematically evaluating your operating environment.

Step 1: Identify Your Operating Environment

Start by documenting your actual operating conditions: temperature range (minimum to maximum), operating pressure (steady-state and spike), fluid type and viscosity, presence of abrasive particles, presence of vibration, and frequency of startups/shutdowns.

These parameters determine which material properties matter most for your application. An operation running constant pressure at moderate temperature prioritizes hardness and wear resistance. An operation with frequent pressure spikes and vibration prioritizes toughness. A corrosive chemical application prioritizes chemical resistance.

Step 2: Evaluate Fluid Compatibility

Identify exactly what you’re sealing. Is it neutral, acidic, alkaline, a solvent, a slurry, or a special process fluid?

Run this simple check: if your fluid is corrosive (strong acid, strong base, or aggressive solvent), silicon carbide is your default choice. If it’s neutral or mildly corrosive, you have flexibility.

Consult your seal manufacturer’s chemical compatibility charts. These charts show which materials handle your specific fluid. A fluid that slowly dissolves tungsten carbide might leave silicon carbide untouched.

Step 3: Assess Pressure and Shock Requirements

Are you running steady pressure or frequent pressure spikes? Do you experience vibration?

Steady moderate pressures (under 2,000 psi) favor silicon carbide for its superior wear resistance. High static pressures (3,000+ psi) favor tungsten carbide for its superior rigidity. Intermittent shock loads or significant vibration favor tungsten carbide for its fracture toughness.

If you’re unsure, check your equipment documentation or ask your pump supplier what pressure ranges and vibration levels are normal.

Step 4: Consider Temperature Demands

What’s your actual seal operating temperature?

Below 200°C: Either material works fine.

200-400°C: Silicon carbide shows advantages but tungsten carbide is adequate.

Above 400°C: Silicon carbide is strongly preferred.

Thermal cycling (frequent temperature changes) strongly favors silicon carbide due to its lower expansion coefficient and superior thermal conductivity.

Step 5: Calculate Total Cost of Ownership

This is the decisive step that many operators skip—and regret.

Compare the initial seal cost against your expected outcomes: how many months of continuous service do you expect? How often do you anticipate replacing the seal? When the seal fails, what’s your downtime cost? How much labor does replacement require?

Run the numbers. A $300 silicon carbide seal that lasts 24 months often beats a $180 tungsten carbide seal that lasts 8 months when you account for three labor visits, three days of downtime, and lost production.

Step 6: Consult Seal Face Combinations

Remember that seal performance depends on the pair of materials, not just one of them.

The typical combinations are:

- Carbon/Silicon Carbide: The most common combination. Carbon provides cost control; silicon carbide provides hardness and thermal performance. This works for most industrial applications.

- Silicon Carbide/Silicon Carbide: When you need maximum performance and chemical resistance. Both faces are ceramic, providing maximum wear resistance. This handles abrasive slurries and corrosive applications.

- Tungsten Carbide/Tungsten Carbide: Maximum pressure and vibration resistance. Both faces are metal-ceramic composite, providing rigidity and toughness.

- Silicon Carbide/Tungsten Carbide: A hybrid approach. Silicon carbide provides hardness and corrosion resistance; tungsten carbide provides toughness. This works for mixed-demand applications.

- Carbon/Tungsten Carbide: High-pressure applications like boiler feed pumps. Carbon provides lubricity; tungsten carbide provides strength.

Your seal supplier can recommend the best pairing for your specific conditions. Don’t assume you can mix and match casually—the two materials must be compatible and complementary.