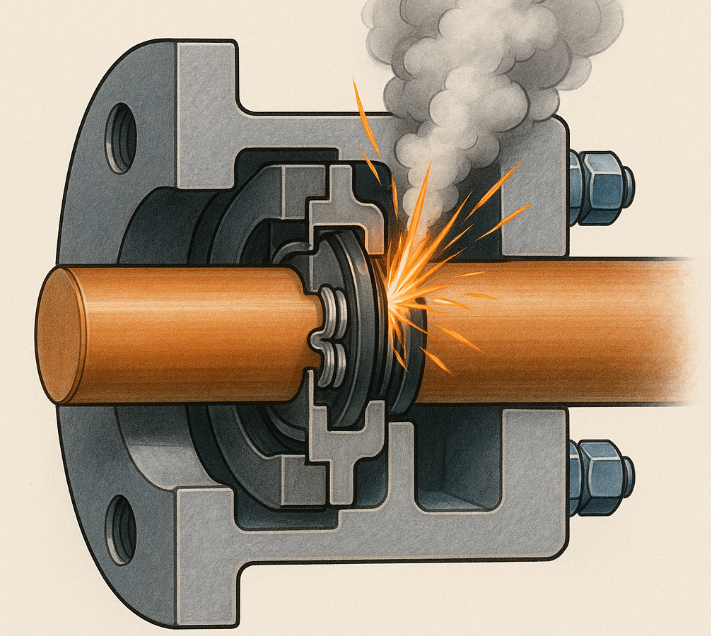

A mechanical seal seat is the stationary half of a seal assembly that prevents fluid leakage in pumps and rotating equipment. It’s a precision-engineered ring that stays fixed in the pump housing while providing a smooth surface for the rotating seal face to run against.

Different seat designs handle different challenges – from simple water pumps to high-pressure chemical reactors. The main types include cup-mounted seats for easy installation, O-ring mounted seats for higher pressures, and clamp-mounted seats for extreme conditions.

Classification of Seal Seats

Seal manufacturers use letter designations like A, B, C, D, E, and G to classify standard seat designs. These letters represent specific geometries and mounting styles that have become industry standards.

Each classification tells you how the seat mounts, what secondary seals it uses, and where it works best.

Type A Seat

Type A seats use an O-ring on their outer diameter to seal against the housing bore. They typically feature an L-shaped cross-section with a groove for the O-ring.

Many Type A seats include an anti-rotation pin that prevents spinning during operation. This design handles pressures up to 600 psi in some configurations. The O-ring provides both the static seal and helps hold the seat in place through compression.

Water pumps and general industrial applications commonly use Type A seats. They offer reliable performance when the bore surface finish meets specifications – usually 32 RMS or smoother.

Type B Seat

Type B seats are another O-ring mounted variant with slightly different proportions than Type A. They often have a shorter L-section or are designed for shallower bores.

John Crane’s Type B family includes variations like BO, BS, and BP for different bore standards. These seats function similarly to Type A but fit specific housing dimensions. The O-ring placement and groove design may differ to accommodate various pump manufacturers’ specifications.

General-purpose pumping applications use Type B seats interchangeably with Type A in many cases. The choice between them often depends on the existing bore dimensions rather than performance differences.

Type C / Type D Seats

Type C and D seats typically use clamp-mounting rather than friction-based retention. These designs feature flange-like shapes secured by gland plates with gaskets on one or both sides.

The clamping mechanism provides extremely secure retention even under shock pressures. These seats cannot rotate or blow out because mechanical compression holds them in place. Heavy-duty applications and large seal designs often specify C or D type seats.

While less common than A, B, or G types, these classifications appear in certain European standards and specialty applications.

Type E Seat

Type E seats often refer to cup-mounted designs used with heavy-duty seals or large single springs. Some manufacturers use this designation for seats compatible with John Crane Type 1 seals.

The design typically features an elastomer boot that provides both sealing and retention. This configuration works well with multi-spring balanced seals in moderate service conditions. The term “Type E” isn’t universally standardized, making it important to verify specifications with your supplier.

Water and light chemical services commonly employ Type E seats where conditions don’t exceed the elastomer’s temperature and chemical limits.

Type G Seat

Type G seats use rubber cup mounting, a design popularized by Burgmann . The rubber boot encases an L-shaped hard ring and holds it in place through friction.

Variations include G4, G6, G9, G13, G50, and G60 for different sizes and profiles. The elastomer cup both seals against the bore and centers the hard face material. This design tolerates slightly rough or out-of-tolerance bores better than O-ring designs.

Pool pumps, water circulation systems, and moderate-duty applications extensively use Type G seats. They install quickly – often by hand with just lubricant – making them popular for maintenance operations.

Design Variations of Seal Seats

Beyond letter classifications, seal seats fall into four main design categories based on their mounting method.

Cup-Mounted Seats (Boot Mounted)

Cup-mounted seats feature an elastomer boot molded around a hard seat ring. The rubber cup provides the seal and holds the seat through friction when pressed into the housing bore.

Installation takes seconds – just lubricate the boot and press it in by hand. The elastomer conforms to minor bore imperfections, accepting surface finishes up to 63 RMS. This forgiveness makes cup seats ideal for field repairs where perfect machining isn’t available.

O-Ring Mounted Seats

O-ring mounted seats use a compressed O-ring to seal between the seat and housing bore. The seat usually has an L-shaped profile with a machined groove for the O-ring.

These seats handle pressures up to 600 psi with proper O-ring selection. The solid seat design conducts heat better than elastomer boots, improving face cooling.

Chemical plants and refineries rely on O-ring mounted seats. The design balances performance, reliability, and reasonable installation complexity for most industrial applications.

Clamp-Mounted Seats

Clamp-mounted seats rely on mechanical compression rather than friction for retention. A gland plate or collar ring holds the seat in place with gaskets providing the seal.

This design prevents any possibility of seat rotation or displacement. High-pressure applications and large diameter seals often require clamped seats for security. The mechanical retention allows use of non-elastomeric seals like graphite for extreme temperatures.

API 682 high-pressure seals and reactor agitators commonly use clamp-mounted seats. The added complexity pays off in reliability for critical applications.

Floating or Distortion-Free Seats

Floating seats incorporate cushioning elements that allow slight movement while maintaining face contact. An elastomer backing or special holder isolates the sealing surface from mounting stresses.

These designs self-align to accommodate shaft movement or thermal growth. The floating element prevents face distortion from over-tightened bolts or temperature changes.

Chemical reactors, hot fluid pumps, and equipment with thermal cycling use floating seats to maintain seal integrity despite changing conditions.