Cantilever type bellows are specialized components used to compensate for dimensional changes caused by temperature fluctuations or mechanical forces in various industrial applications. However, selecting the right type of bellows for a given application can be challenging due to the diverse range of designs, materials, and performance characteristics available.

In this article, we will provide a comprehensive overview of cantilever type bellows, including their design, construction, advantages, disadvantages, and typical applications. We will also compare cantilever type bellows with other common bellows types to help you make an informed decision when specifying these critical components for your projects.

What Are Cantilever Type Bellows

Cantilever type bellows are a specialized type of bellows design characterized by their unique construction and geometry. They consist of multiple nested convoluted diaphragms or plates attached to a common center spool or ring. The outer edges of these diaphragms are welded to end spools in an offset or stepped pattern, resembling a cantilever spring arrangement.

This distinctive cantilever design allows for significant axial deflection and lateral displacement while maintaining a high degree of stiffness in the radial direction. The convoluted plates act like cantilever springs, flexing and deforming to accommodate motion along the bellows axis. This spring-like behavior enables cantilever bellows to effectively absorb vibrations, compensate for misalignments, and accommodate thermal expansion or contraction in piping systems.

Design and Construction of Cantilever Type Bellows

- Diaphragms or Plates: Cantilever bellows are constructed using multiple thin, convoluted metal diaphragms or plates.

- Central Spool or Ring: The diaphragms are attached to a central spool or ring, which serves as the core of the bellows assembly. It also acts as a mounting point for connecting the bellows to other components in the piping system.

- End Spools: The outer edges of the diaphragms are welded to end spools in an offset or stepped pattern. The end spools are typically designed with flanges or other connection features to facilitate integration with the piping system.

Advantages of Cantilever Type Bellows

- High Lateral Flexibility: The cantilever leaf structure allows for significant lateral movement and angulation.

- Compact Design: Cantilever bellows feature a space-saving design that enables them to be used in applications with limited installation space.

- Low Spring Rate: The thin cantilever leaves provide a very low spring rate, meaning cantilever bellows exert minimal force and resistance when compressed or extended.

- Durable Construction: Cantilever bellows are typically constructed from high-strength stainless steel. The all-metal welded construction provides excellent durability, corrosion resistance, and the ability to withstand high temperatures and pressures.

Disadvantages of Cantilever Type Bellows

- Limited Pressure Capability: Due to the thin cantilever leaves, these bellows have a lower pressure rating compared to other types like formed or edge-welded bellows. Attempting to use them at higher pressures may cause the leaves to deform.

- Reduced Axial Stiffness: The high lateral flexibility of cantilever bellows comes at the cost of reduced axial stiffness. They have a lower resistance to compression loads compared to other stiffer bellows types.

- Larger Size: Although very compact in the axial direction, cantilever bellows require more radial space to accommodate the lateral flexing of the leaves. The overall diameter of a cantilever bellow will be larger relative to its stroke compared to other types.

- Higher Cost: The complex geometry of the individual cantilever leaves often makes these bellows more expensive to manufacture compared to simpler formed or welded designs.

- Sensitivity to Solid Particles: The small spaces between the sliding leaves can potentially trap solid particles, causing abrasion and wear.

Applications of Cantilever Type Bellows

- Exhaust Connectors: Cantilever bellows are commonly used as flexible exhaust connectors and expansion joints in engine exhaust systems. They allow relative movement between exhaust components while maintaining a leak-proof seal, accommodating thermal expansion and vibration.

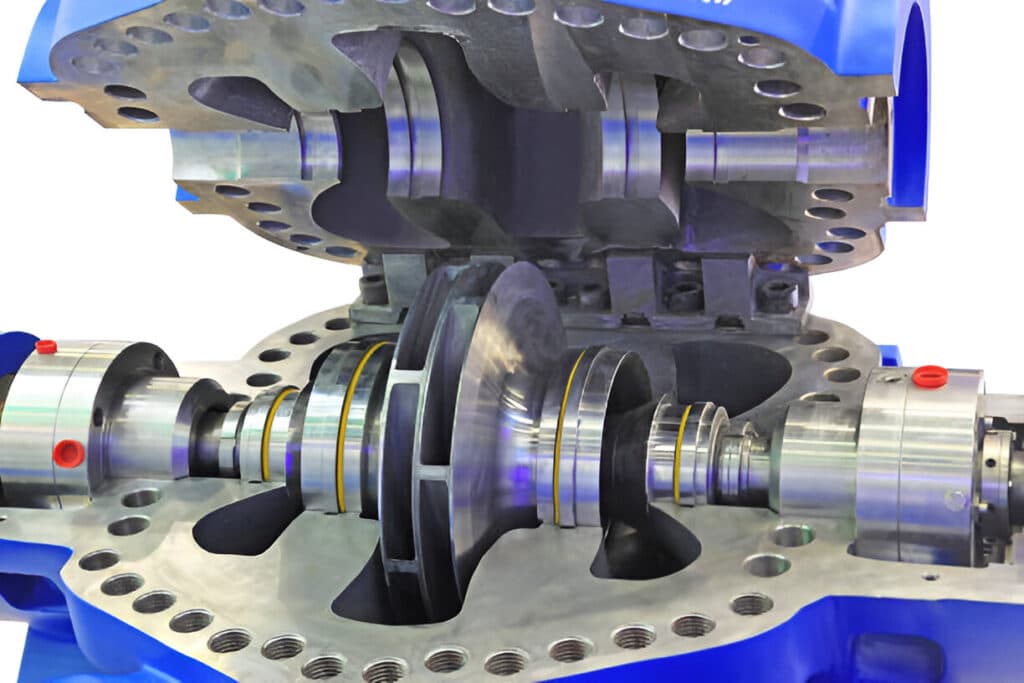

- Mechanical Seals: In rotary equipment like pumps, mixers, and compressors, cantilever bellows serve as non-rotating sealing elements in mechanical seal assemblies. The bellows maintain a flexible seal around the rotating shaft, accommodating shaft misalignment and axial movement.

- Valve Stem Seals: Cantilever bellows are used as stem seals in high-performance valves to provide a reliable, flexible seal around the moving valve stem. The bellows maintain sealing integrity despite side loads or misalignment, ensuring leak-tight shutoff.

- Aerospace: In aircraft and spacecraft, cantilever bellows find use in flexible ducting, thermal expansion joints, and mechanical seals. Their ability to allow movement and absorb vibrations in a compact envelope is beneficial in these weight-sensitive applications.

- Medical Devices: The biocompatibility and flexibility of stainless steel cantilever bellows make them suitable for medical device applications. They are used in endoscopes, surgical instruments, and implantable devices to enable precise articulation and fluid/gas sealing.

- Semiconductor Manufacturing: In semiconductor fabrication equipment, cantilever bellows are used as dynamic seals in wafer handling and vacuum chamber feed-throughs. They maintain vacuum or process gas integrity while allowing necessary movement and adjustment.

- Robotics: Cantilever bellows serve as flexible joints and dynamic sealing elements in robotic arms and manipulation devices. They enable smooth articulation and rotary motion in compact robotic assemblies while protecting internal components.

- Precision Instruments: In optical devices, sensors, and metrology instruments, cantilever bellows provide precise sealing and movement for focus adjustment, zoom mechanisms, and sample positioning stages. Their frictionless flexing and low hysteresis contribute to high precision.

Comparison with Other Bellows Types

| Feature | Cantilever Type | U-Shaped | Fully Articulated |

|---|---|---|---|

| Axial Stroke Capacity | Low to Medium | High | Very High |

| Lateral Deflection Allowance | Low | Medium | Very High |

| Angular Rotation Allowance | Low | Medium | Very High |

| Pressure Resistance | Medium | Medium to High | Low to Medium |

| Spring Rate | High | Medium | Low |

| Vibration Damping | Low | Medium | High |

| Cycle Life | Medium to High | Medium to High | Low to Medium |

| Compactness | High | Low | Very Low |

| Manufacturing Cost | Low to Medium | Medium | High |