What Are Silicon Carbide Mechanical Seals

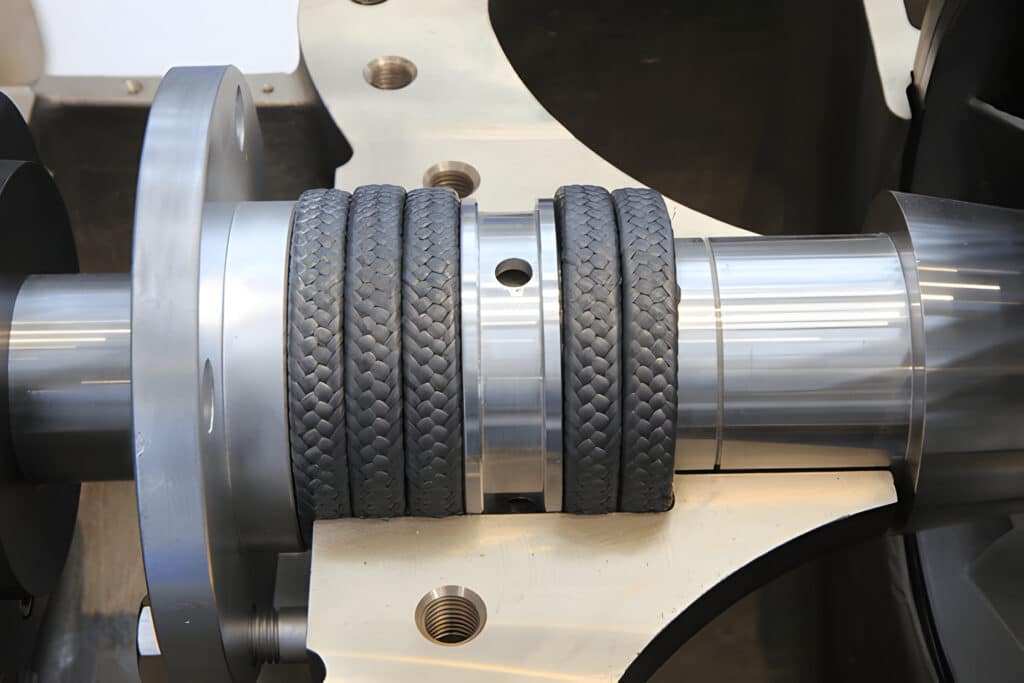

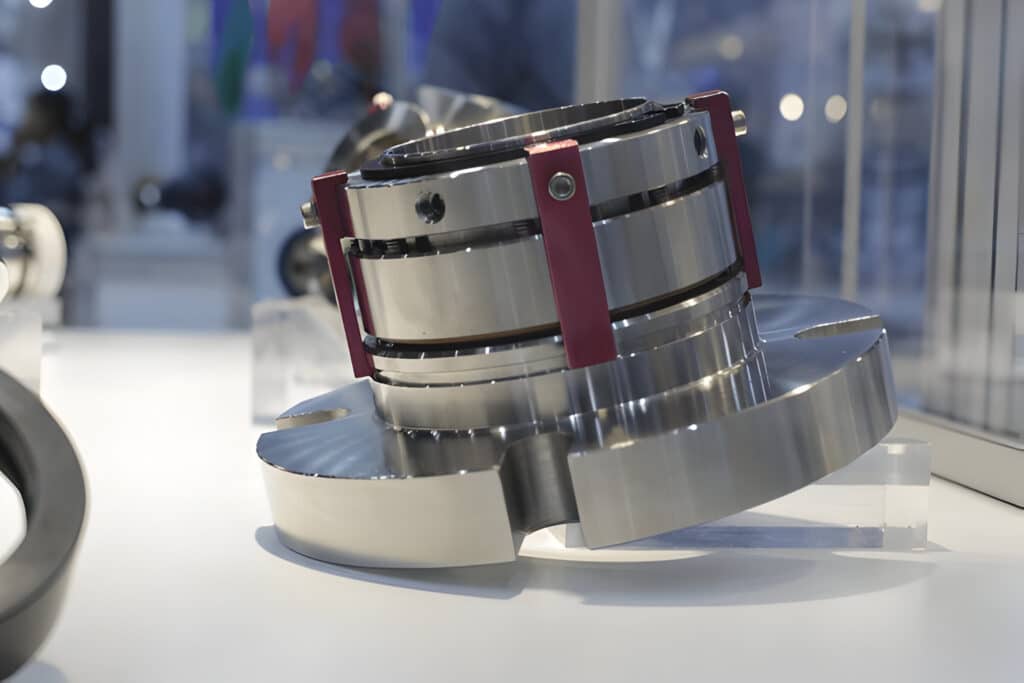

Silicon carbide mechanical seals are highly durable and reliable sealing solutions designed for demanding industrial applications. These seals utilize silicon carbide, a ceramic material known for its exceptional hardness, wear resistance, and chemical inertness.

Silicon carbide seal faces provide excellent resistance to abrasion, corrosion, and high temperatures, making them ideal for use in harsh environments such as pumps handling abrasive slurries, chemically aggressive fluids, or high-temperature media.

Key Properties of Silicon Carbide

- Excellent Abrasion and Corrosion Resistance: Silicon carbide’s high hardness and chemical inertness enable it to withstand highly abrasive and corrosive conditions, extending seal life and reducing maintenance costs.

- Low Coefficient of Friction and Thermal Expansion: The low friction coefficient of silicon carbide minimizes heat generation and wear, while its low thermal expansion ensures stable performance across a wide temperature range.

- Exceptional Heat Dispersion Properties: Silicon carbide’s high thermal conductivity allows for efficient heat dissipation, preventing thermal distortion and maintaining seal integrity in high-temperature applications.

- High Chemical Resistance: Silicon carbide is resistant to a broad range of chemicals, including strong acids and bases, making it suitable for use in diverse industrial processes.

Advantages of Silicon Carbide Seals

- Extended Seal Life and Reduced Maintenance in Demanding Applications: The superior abrasion, corrosion, and temperature resistance of silicon carbide seals significantly extends their service life, minimizing downtime and maintenance costs.

- Improved Performance in Abrasive, Corrosive, and High-Temperature Environments: Silicon carbide seals maintain their integrity and performance in challenging conditions, ensuring reliable operation and reduced process disruptions.

- Lower Friction and Heat Generation Compared to Other Hard Face Materials: The low friction coefficient of silicon carbide results in less heat generation and wear, improving seal performance and longevity.

- Ability to Be Re-Lapped and Refurbished for Repeat Use: Silicon carbide seal faces can be re-lapped and refurbished, allowing for multiple uses and further extending their service life.

Applications of Silicon Carbide Seals

- Pumps Handling Abrasive Slurries, Chemically Aggressive Fluids, or High-Temperature Media

- Industries Such as Oil & Gas, Chemical Processing, Mining, Wastewater Treatment

Types of Silicon Carbide Grades

Silicon carbide is available in different grades, each with specific properties tailored to various applications. Some common grades include:

- Sintered Silicon Carbide (SSiC): A high-purity, fine-grained material with excellent hardness, wear resistance, and chemical inertness.

- Reaction-Bonded Silicon Carbide (RBSiC): Produced by infiltrating silicon into a porous carbon preform, resulting in a strong, lightweight material with good thermal shock resistance.

- Nitride-Bonded Silicon Carbide (NBSiC): Offers high strength, fracture toughness, and thermal shock resistance, making it suitable for demanding thermal cycling applications.

FAQs

Is It Safe to Touch Silicon Carbide?

While silicon carbide is non-toxic, it is an abrasive material that can cause skin irritation or cuts. It is recommended to wear protective gloves when handling silicon carbide seal faces or powder to prevent potential injuries.

Which Is Better: Silicon Carbide or Tungsten Carbide Seal Faces?

Silicon carbide is often preferred in highly abrasive, corrosive, or high-temperature environments due to its superior hardness, chemical inertness, and heat resistance.

Tungsten carbide is more resistant to impact and thermal shock, making it a better choice for applications with high mechanical loads or thermal cycling.