What Is Elastomer Bellows Mechanical Seal

Elastomer bellows mechanical seals are specialized sealing devices designed to prevent leakage in rotating equipment, such as pumps, compressors, and mixers. These seals consist of a flexible elastomeric bellows element that acts as a dynamic seal between the rotating shaft and the stationary housing. The bellows is typically made from high-performance elastomers, such as fluoroelastomers (FKM), perfluoroelastomers (FFKM), or hydrogenated nitrile butadiene rubber (HNBR), which offer excellent chemical resistance, thermal stability, and mechanical properties.

The primary function of an elastomer bellows mechanical seal is to contain process fluids within the equipment while accommodating shaft misalignment, vibration, and axial movement. The flexibility of the bellows allows it to maintain a tight seal against the shaft, even under dynamic operating conditions.

How Do Elastomer Bellows Mechanical Seals Work

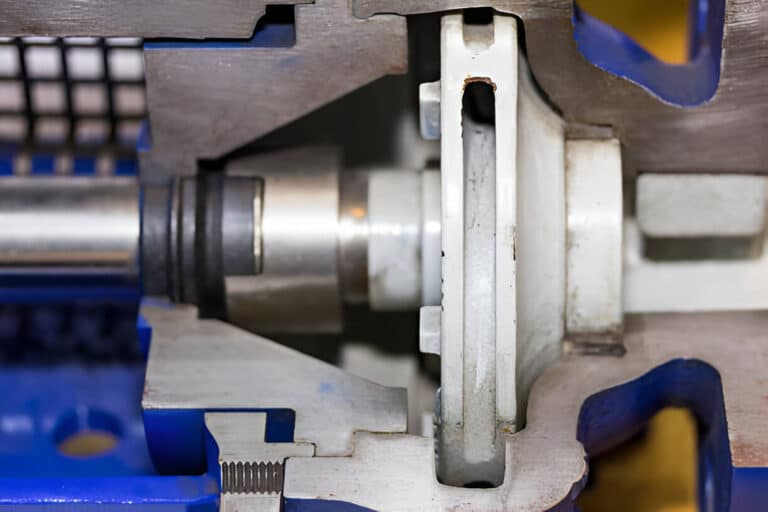

Elastomer bellows mechanical seals operate on the principle of fluid film lubrication. The seal faces, typically made of hard materials such as silicon carbide, tungsten carbide, or ceramic, are held in close contact by the spring force of the bellows. As the shaft rotates, a thin fluid film is generated between the seal faces, which lubricates and cools the sealing interface. This fluid film helps to minimize wear and friction, extending the life of the seal.

The bellows element plays a crucial role in the functioning of the seal. It provides the flexibility needed to maintain contact between the seal faces, even when the shaft is misaligned or subjected to axial movement. The bellows also acts as a secondary seal, preventing leakage from the primary sealing interface. In some designs, the bellows is equipped with a secondary sealing lip that provides additional protection against leakage.

Advantages of Elastomer Bellows Mechanical Seals

- Excellent sealing performance: The flexible bellows design allows for a tight seal against the shaft, minimizing leakage and improving process efficiency.

- Accommodation of shaft misalignment and movement: The bellows element can handle shaft misalignment, vibration, and axial movement without compromising sealing performance.

- Wide chemical compatibility: Elastomer materials such as FKM, FFKM, and HNBR offer excellent resistance to a wide range of chemicals, making them suitable for use in diverse industrial applications.

- High-temperature stability: Advanced elastomer compounds can withstand temperatures up to 325°C (617°F), making them suitable for high-temperature applications.

- Low friction and wear: The fluid film lubrication between the seal faces minimizes friction and wear, extending the life of the seal and reducing maintenance requirements.

- Compact design: Elastomer bellows mechanical seals have a compact, space-saving design that makes them suitable for use in a wide range of equipment sizes and configurations.

Types of Elastomer Bellows Mechanical Seals

- Single bellows seals: These seals have a single bellows element that provides both the primary and secondary sealing functions. They are suitable for general-purpose applications with moderate pressure and temperature requirements.

- Double bellows seals: These seals have two bellows elements arranged in series, providing an additional layer of protection against leakage. They are used in more demanding applications with higher pressure or temperature requirements, or where enhanced safety and reliability are critical.

- Cartridge seals: These are pre-assembled units that combine the seal head, bellows, and gland into a single, easy-to-install component. They offer improved reliability and simplify maintenance procedures.

- Split seals: These are designed with a two-part gland and seal head that allow for installation and removal without disassembling the equipment. They are particularly useful in applications where frequent seal replacement is required or where equipment downtime must be minimized.

- Dual seals: These consist of two independent sealing elements, each with its own set of seal faces and bellows. They provide an extra level of protection against leakage and are often used in critical applications where process fluid containment is paramount.

What Are Elastomer Bellows Mechanical Seals Used for

- Chemical processing: Seals made from chemically resistant elastomers, such as FKM or FFKM, are used in pumps, mixers, and other equipment handling aggressive chemicals, solvents, or acids.

- Petrochemical and refining: Elastomer bellows seals are used in pumps, compressors, and other rotating equipment in the petrochemical and refining industries, where they must withstand high temperatures, pressures, and exposure to hydrocarbons.

- Pharmaceutical and food processing: Seals made from FDA-compliant elastomers, such as EPDM or PTFE-encapsulated FKM, are used in equipment handling food, beverages, and pharmaceutical products, ensuring process purity and safety.

- Water and wastewater treatment: Elastomer bellows seals are used in pumps, mixers, and other equipment in water and wastewater treatment plants, where they must resist exposure to chlorine, biocides, and other treatment chemicals.

- Power generation: In power plants, elastomer bellows seals are used in pumps, turbines, and other rotating equipment, where they must withstand high temperatures, pressures, and exposure to steam or cooling water.

- Pulp and paper: Elastomer bellows seals are used in pumps, refiners, and other equipment in the pulp and paper industry, where they must resist exposure to corrosive chemicals, abrasive slurries, and high temperatures.

- Mining and mineral processing: In mining and mineral processing applications, elastomer bellows seals are used in pumps, mixers, and other equipment handling abrasive slurries, corrosive reagents, and high-pressure fluids.