Nuclear power is a vital source of energy, and pressurized water reactors (PWRs) are its most common implementation. These reactors use a controlled chain reaction to generate heat, which drives the turbines that produce electricity.

This article delves into the inner workings of PWRs, discussing their components, processes, and characteristics. We will examine how fission produces energy and explore how the reactor’s systems are designed and the advantages and disadvantages of this design.

What Is a Pressurized Water Reactor

A Pressurized Water Reactor (PWR) is a type of nuclear reactor that utilizes ordinary water, known as light water, as both a coolant and a neutron moderator. This design is characterized by maintaining the water in the primary coolant loop under high pressure. This prevents the water from boiling, even at high operating temperatures. The generated heat is then transferred to a secondary loop, producing steam for electricity generation. PWRs are the most common type of nuclear reactor used in nuclear power plants globally.

How Pressurized Water Reactors Work

The operation of a PWR involves several key processes, including nuclear fission, heat transfer, steam generation, electricity generation, and water recycling.

Nuclear Fission

Nuclear fission is the process at the core of energy production in a PWR. It involves the splitting of heavy atomic nuclei, such as uranium, when they are bombarded with neutrons. This splitting process releases a large amount of energy in the form of heat and also releases more neutrons. These released neutrons can then induce further fission reactions, creating a self-sustaining chain reaction within the reactor core. This chain reaction is carefully controlled by using control rods that absorb neutrons, ensuring the reaction rate is stable and safe.

Heat Transfer

The heat generated through nuclear fission in the reactor core is transferred to the primary coolant loop. This loop contains water that is kept under high pressure to prevent it from boiling. The heated water is circulated through the reactor core and then to the steam generator. In the steam generator, this heated water passes through tubes, transferring its heat to the water in the secondary loop. The primary coolant loop operates as a closed system, circulating the same water repeatedly.

Steam Generation

The secondary loop in a PWR is where steam is generated. The heat transferred from the primary loop to the secondary loop heats the water in the secondary loop. This water converts into steam which is at high pressure. This high-pressure steam is used to drive the turbines. The separation of the primary and secondary water loops ensures that any radioactive materials remain contained in the primary loop, improving safety.

Electricity Generation

The high-pressure steam produced in the steam generator is directed to a turbine. The force of the steam rotates the blades of the turbine, which is connected to an electricity generator. The generator converts the mechanical energy of the rotating turbine into electrical energy. This electricity is then distributed through power grids to homes and industries.

Condensation and Water Recycling

After passing through the turbine, the steam is cooled and condensed back into water in a condenser. This process allows the water to be recycled back into the secondary loop. It is preheated and returned to the steam generator to be used again. This closed-loop system minimizes water consumption and maximizes efficiency.

Components of Pressurized Water Reactors

Several key components make up a PWR:

Reactor Core

The reactor core is where nuclear fission takes place and consists of:

- Fuel Rods and Assemblies: Fuel rods, containing the nuclear fuel, are arranged into assemblies. These assemblies are submerged in water within the reactor core.

- Fuel: Enriched uranium is used as the fuel. It is typically in the form of ceramic pellets.

- Control Rods: These rods are made of neutron-absorbing materials, such as boron or cadmium. They are inserted into the core to regulate the rate of nuclear fission by absorbing neutrons and maintaining a stable chain reaction.

Reactor Pressure Vessel

The reactor pressure vessel is a large, robust container that houses the reactor core, coolant, and other internal components. It is designed to withstand high temperatures and pressures.

Moderator and Coolant

Ordinary water (light water) serves as both the neutron moderator and the coolant in a PWR. As a moderator, it slows down the neutrons released during fission, making them more likely to cause additional fission reactions. As a coolant, it removes the heat generated by fission.

Pressurizer

The pressurizer is a vessel connected to the primary loop that maintains the system at a high, constant pressure. It uses heaters and water to control the primary coolant pressure, keeping it from boiling.

Steam Generator

The steam generator transfers heat from the primary coolant loop to the secondary loop. Water in the secondary loop is turned to steam, which is then used to drive the turbines.

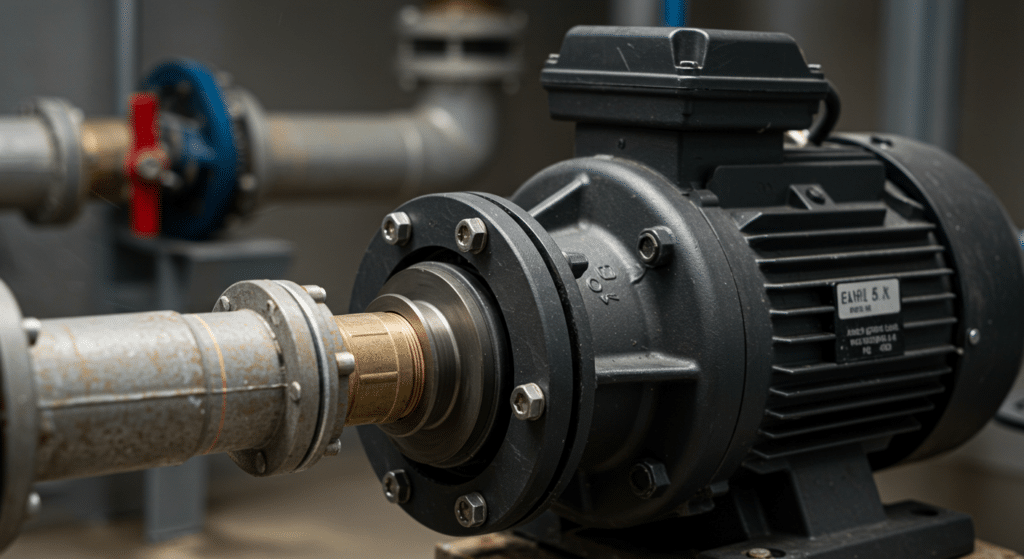

Primary Coolant Loop

The primary coolant loop is a closed system containing the reactor core, pressurizer, and steam generator. It circulates high-pressure water to transfer heat from the reactor core to the steam generator.

Secondary Coolant Loop

The secondary coolant loop contains the steam generator, turbine, condenser, and associated piping. It is separate from the primary loop. It carries steam to the turbine, and returns water to the steam generator.

Key Characteristics of Pressurized Water Reactors

Several key characteristics define PWRs:

- Pressurized Water System: The primary coolant loop is kept at a high pressure to prevent the water from boiling, allowing for efficient heat transfer at high temperatures.

- Two-Loop System: The separation of the primary and secondary coolant loops prevents radioactive materials from reaching the steam turbine and ensures safety.

- Light Water Reactor: PWRs use ordinary water as both the neutron moderator and coolant, which is both readily available and effective for the process.

Advantages of Pressurized Water Reactors

- Stable Operation: The use of a negative temperature coefficient ensures that the reactor is self-regulating. If the temperature increases, the rate of fission decreases, preventing uncontrolled power surges.

- Effective Heat Transfer: Water is an excellent coolant, making heat removal from the reactor core efficient.

- Separation of Loops: The separation of the primary and secondary loops prevents radioactive materials from entering the steam turbine system, enhancing safety.

Disadvantages of Pressurized Water Reactors

- High Pressure: The high pressure in the primary coolant loop requires robust and costly containment systems.

- Enriched Uranium: PWRs require enriched uranium fuel, which is more expensive and complex to produce.

- Corrosion: The high temperatures and pressures within the reactor system can lead to corrosion of components over time, requiring regular maintenance and inspections.

- Potential for Accidents: While safety measures are in place, the possibility of a serious accident with radiation release remains a concern, requiring advanced safety features and emergency planning.

- Waste Management: PWRs produce radioactive waste, which requires careful handling, storage, and disposal, presenting a long-term environmental challenge.