Are you struggling to choose between a cartridge seal and mechanical seal for your machinery application? Making the wrong decision can lead to equipment failure, costly downtime, and maintenance headaches.

With so many factors to consider – from assembly and installation to cost and availability – it’s no wonder many machinery professionals feel overwhelmed and unsure about which seal type is right for their needs.

In this blog post, we’ll break down the key differences between cartridge seals and mechanical seals, giving you the knowledge you need to make an informed decision for your specific application. Read on to learn about the pros and cons of each seal type and gain clarity on which one will deliver optimal performance, reliability and value for your machinery.

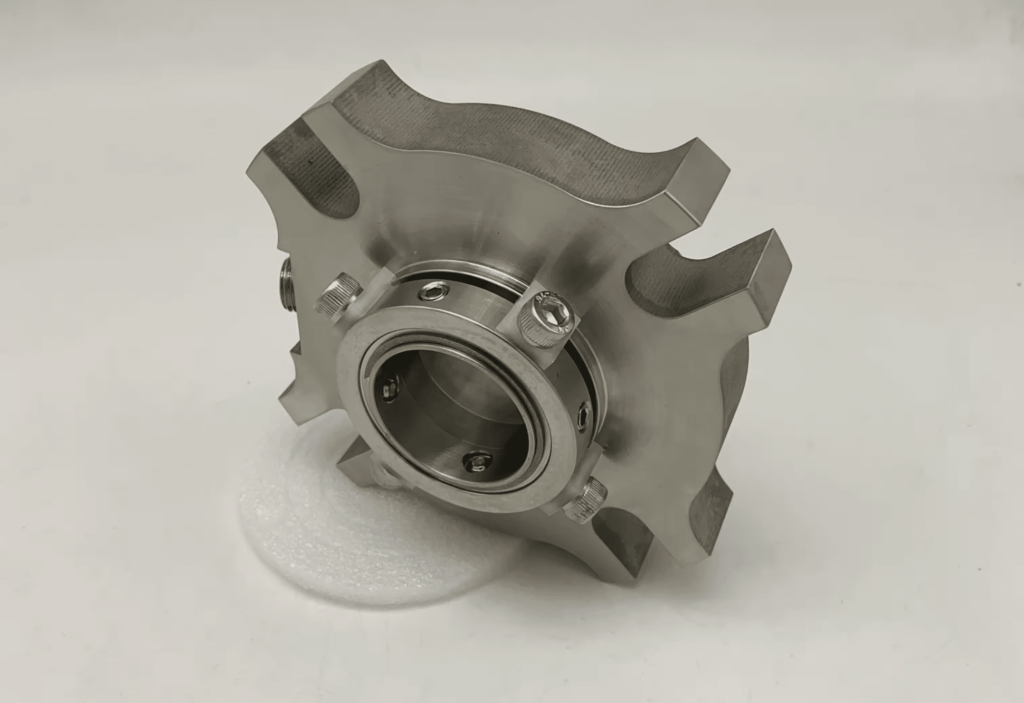

What Is Cartridge Seal

A cartridge seal is a pre-assembled sealing unit that consists of a seal head, sleeve, gland plate, and other components, all packaged together in a single cartridge. This design allows for quick and easy installation, as the entire unit can be mounted onto the equipment without the need for individual component assembly. Cartridge seals are designed to be more robust and reliable compared to traditional component seals.

What Is Mechanical Seal

A mechanical seal is a sealing device that consists of two flat surfaces, one stationary and one rotating, that are pressed together to create a seal. The stationary surface, known as the seal face, is typically made of a hard material such as silicon carbide or tungsten carbide, while the rotating surface, called the mating ring, is usually made of a softer material like carbon or silicon carbide. Mechanical seals rely on the contact between these two surfaces to prevent fluid leakage.

Difference Between Cartridge Seal and Mechanical Seal

Assembly

Cartridge seals come pre-assembled, with all the necessary components contained within a single unit.

Mechanical seals require individual components to be assembled on-site.

Installation

The installation process for cartridge seals is significantly simpler and faster compared to mechanical seals. With a cartridge seal, the entire unit can be installed as a single piece, minimizing the time required for installation and reducing downtime.

Mechanical seals require each component to be installed separately, which can be a complex and lengthy process.

Maintenance

Cartridge seals generally require less maintenance compared to mechanical seals. The pre-assembled design of cartridge seals makes it easier to replace the entire unit when necessary, without the need for disassembly and reassembly of individual components.

Mechanical seals may require more frequent maintenance, as individual components may need to be replaced or adjusted to maintain optimal performance.

Cost

While cartridge seals may have a higher initial cost compared to mechanical seals, they often prove to be more cost-effective in the long run.

Availability

Cartridge seals are widely available from various manufacturers and can be easily sourced for most applications. Many manufacturers offer standard cartridge seal designs that are compatible with a range of equipment types and sizes.

Mechanical seals, while also widely available, may require more customization to fit specific equipment requirements, which can impact their availability and lead times.

Size

Cartridge seals are generally larger in size compared to mechanical seals due to their pre-assembled design.

Mechanical seals, being composed of individual components, can be more compact and suitable for applications with tight space constraints.

Standardization

Cartridge seals benefit from a higher degree of standardization compared to mechanical seals. Many manufacturers offer standardized cartridge seal designs that are interchangeable across different equipment types and brands.

Mechanical seals, while also subject to standardization efforts, may require more customization to meet specific equipment requirements.

Applications

Cartridge seals are particularly well-suited for applications that require frequent seal replacement, such as boiler feed water pumps, petroleum pipeline pumps, and reactor coolant pumps.

Mechanical seals remain a good choice for smaller, general purpose applications where standardization is important and the cost of downtime is not as high. They are used extensively in transfer pumps, water circulating pumps, and utility applications.