What Is the Main Purpose of a Mechanical Seal

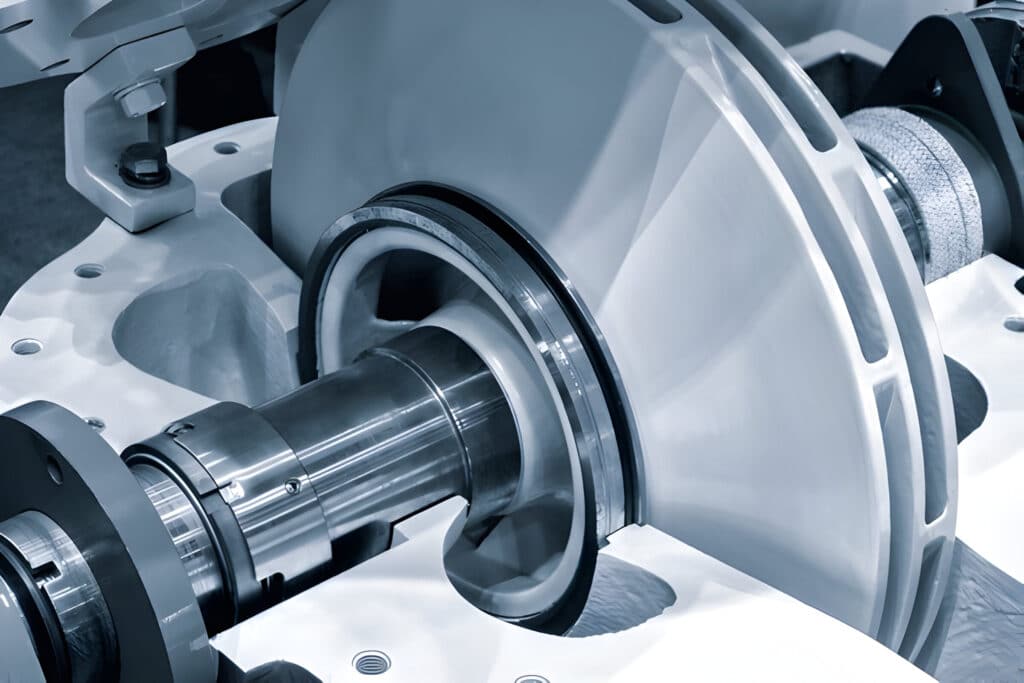

The primary function of a mechanical seal is to prevent the leakage of process fluids from equipment while allowing the rotating shaft to pass through the stationary housing. This is achieved by creating a tight seal between the rotating and stationary components of the seal, which are typically made of durable, wear-resistant materials such as silicon carbide, tungsten carbide, or stainless steel.

Mechanical seals are designed to withstand a range of operating conditions, including high pressures, temperatures, and corrosive environments, making them suitable for a variety of industries and applications.

Advantages of Mechanical Seals

- Reduced leakage: Mechanical seals provide a tight seal between the rotating shaft and stationary housing, minimizing fluid leakage compared to traditional packing seals.

- Lower maintenance costs: While the initial cost of mechanical seals may be higher than other sealing methods, they require less frequent maintenance and have a longer lifespan.

- Versatility: Mechanical seals are suitable for a wide range of industries and applications, including chemical plants, food processing, pharmaceuticals, and water applications. They can handle various process fluids, pressures, and temperatures.

- Improved efficiency: By providing a reliable seal, mechanical seals help maintain optimal performance of pumps and other rotating equipment. This results in increased efficiency and reduced energy consumption.

- Enhanced safety: Mechanical seals help prevent leaks and spillage, reducing safety hazards in the workplace. They are especially crucial in applications involving dangerous or corrosive fluids.

- Compact design: Mechanical seals require minimal space compared to other sealing methods, making them suitable for applications with limited space, such as gearbox housings or small pump casings.

- Compliance with industry standards: Modern mechanical seal designs meet stringent industry requirements, ensuring compatibility with a variety of applications and adherence to safety standards.

- Reduced environmental impact: By minimizing leaks and wastage, mechanical seals contribute to a cleaner and more environmentally friendly manufacturing process.

- Increased equipment reliability: The reliable sealing performance of mechanical seals helps extend the life of pumps and other rotating equipment, reducing the frequency of equipment failures and unplanned downtime.

- Customization options: Mechanical seals can be customized to meet specific application requirements, such as those found in high-pressure or extreme temperature conditions.

Disadvantages of Mechanical Seals

- Higher initial cost: Compared to traditional packing seals, mechanical seals generally have a higher upfront cost due to their more complex design and precision manufacturing requirements.

- Compatibility issues: Some mechanical seal designs may not be compatible with certain types of process fluids or operating conditions, such as highly abrasive or corrosive environments, potentially leading to premature seal failure.

- Limited space requirements: Mechanical seals typically require more physical space within the pump housing than gland packing, which can be challenging in applications with limited available space.

- Potential for catastrophic failure: In the event of a mechanical seal failure, the consequences can be more severe than with traditional packing seals, potentially resulting in significant fluid leakage and safety hazards.

- Dependent on proper seal chamber environment: The reliable operation of mechanical seals heavily depends on maintaining the proper seal chamber environment, including appropriate flush fluid, pressure, and temperature conditions.

- Secondary maintenance costs: While mechanical seals generally require less frequent maintenance than packing seals, when maintenance is needed, the associated costs can be higher due to the need for specialized tools and expertise.

- Not suitable for all applications: Some pumps, such as those handling highly abrasive slurries or operating at extremely high temperatures, may not be suitable for mechanical seals and may require alternative sealing solutions.