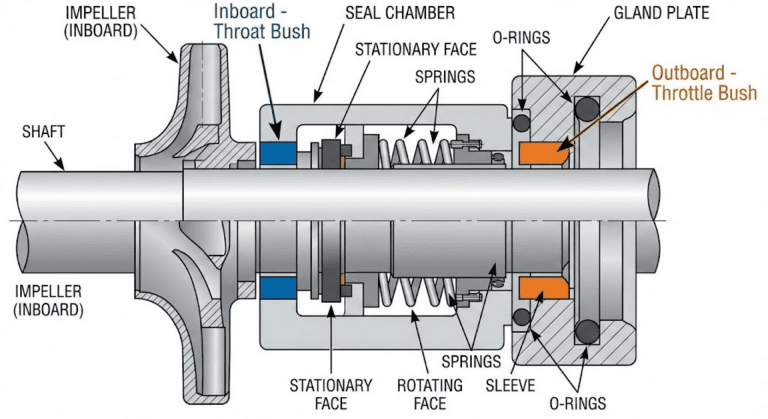

In industrial applications, mechanical seals play a crucial role in preventing leakage and ensuring efficient operation. Two popular materials used in mechanical seals are carbon and silicon carbide. This article will explore the composition, advantages, and disadvantages of each material to help you make an informed decision when selecting a mechanical seal for your specific needs.

Composition and Structure of Carbon Mechanical Seal

Carbon mechanical seals are made from a combination of carbon graphite and impregnated resins. The carbon graphite provides excellent thermal conductivity and lubricity, while the impregnated resins enhance the seal’s mechanical strength and chemical resistance. The structure of carbon mechanical seals is typically a homogeneous, fine-grained matrix that ensures consistent performance and durability.

Advantages of Carbon Mechanical Seal

Carbon mechanical seals offer several advantages, including:

- Excellent thermal conductivity, which helps dissipate heat and prevent thermal distortion

- High lubricity, reducing friction and wear on the seal faces

- Good chemical resistance to a wide range of fluids

- Lower cost compared to silicon carbide seals

Disadvantages of Carbon Mechanical Seal

Despite their advantages, carbon mechanical seals also have some limitations:

- Lower hardness and wear resistance compared to silicon carbide

- Susceptibility to abrasive media, which can lead to premature wear

- Limited temperature range, typically up to 400°C (752°F)

Composition and Structure of Silicon Carbide Mechanical Seal

Silicon carbide mechanical seals are manufactured using high-purity silicon carbide powder, which is sintered at high temperatures to create a dense, hard, and wear-resistant material. The resulting structure is a uniform, fine-grained matrix with excellent mechanical and thermal properties. Silicon carbide seals can be either solid or composite, with composite seals featuring a silicon carbide face bonded to a metal backing.

Advantages of Silicon Carbide Mechanical Seal

Silicon carbide mechanical seals provide several advantages over carbon seals:

- Exceptional hardness and wear resistance, making them ideal for abrasive environments

- High thermal conductivity, enabling efficient heat dissipation

- Excellent chemical resistance to a wide range of aggressive media

- Wide operating temperature range, up to 800°C (1,472°F)

Disadvantages of Silicon Carbide Mechanical Seal

While silicon carbide seals offer superior performance in many applications, they also have some drawbacks:

- Higher cost compared to carbon seals due to the more complex manufacturing process

- Brittleness, which can lead to chipping or cracking if not handled properly

- Requirement for a high-quality counter face material to ensure optimal performance

The Difference between Carbon and Silicon Carbide Mechanical Seal

| Property | Carbon | Silicon Carbide |

|---|---|---|

| Compressive (Crushing) Strength (MPa) | 100-200 | 2000-3000 |

| Elastic (Young’s, Tensile) Modulus (GPa) | 10-30 | 350-450 |

| Poisson’s Ratio | 0.2-0.3 | 0.15-0.2 |

| Tensile Strength (MPa) | 20-50 | 200-400 |

| Maximum Temperature (°C) | 400 | 800 |

| Specific Heat Capacity (J/kg·K) | 700-1000 | 600-800 |

| Thermal Conductivity (W/m·K) | 10-20 | 100-150 |

| Thermal Expansion (10^-6/K) | 4-8 | 3-5 |

| Electrical Resistivity Order of Magnitude (Ω·m) | 10^-5 – 10^-4 | 10^1 – 10^3 |

| Density (g/cm³) | 1.6-1.9 | 3.1-3.2 |

Conclusion

When selecting a mechanical seal material, it is essential to consider the specific requirements of your application.

Carbon mechanical seals offer good performance at a lower cost, making them suitable for many general-purpose applications. Silicon carbide seals, on the other hand, provide superior hardness, wear resistance, and temperature capability, making them ideal for demanding environments with abrasive media or high temperatures.

By understanding the composition, advantages, and disadvantages of each material, you can make an informed decision and ensure optimal performance and reliability in your industrial processes.