Choosing the wrong seal for your compressor or pump can cost you hundreds of thousands of dollars in wasted energy, unplanned downtime, and environmental fines. I’ve seen plants struggle with this decision, and honestly, it’s not as complicated as it seems once you understand how each technology actually works.

Here’s the short answer: dry mechanical seals use a thin gas film (about 3-6 microns thick) to keep seal faces separated without touching, while wet mechanical seals maintain a liquid film (roughly 1 micron) for lubrication and cooling. Dry seals consume up to 80% less power and cut emissions by as much as 97%, but they need clean, dry gas to work properly. Wet seals handle dirty and hazardous fluids better and cost less upfront, though they require more maintenance over time.

How Do Dry and Wet Mechanical Seals Work Differently?

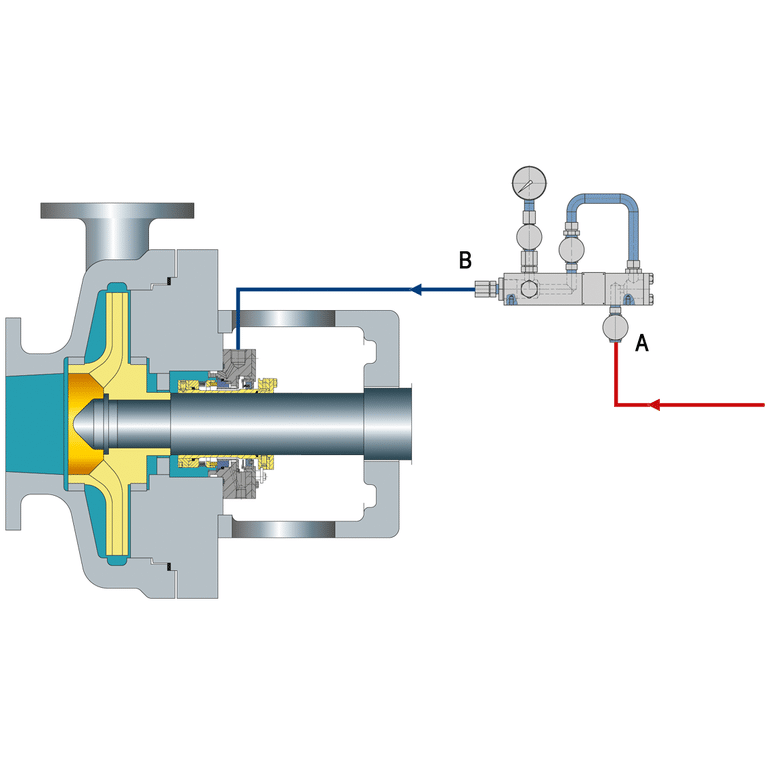

How Does a Dry Gas Seal Create a Non-Contacting Seal?

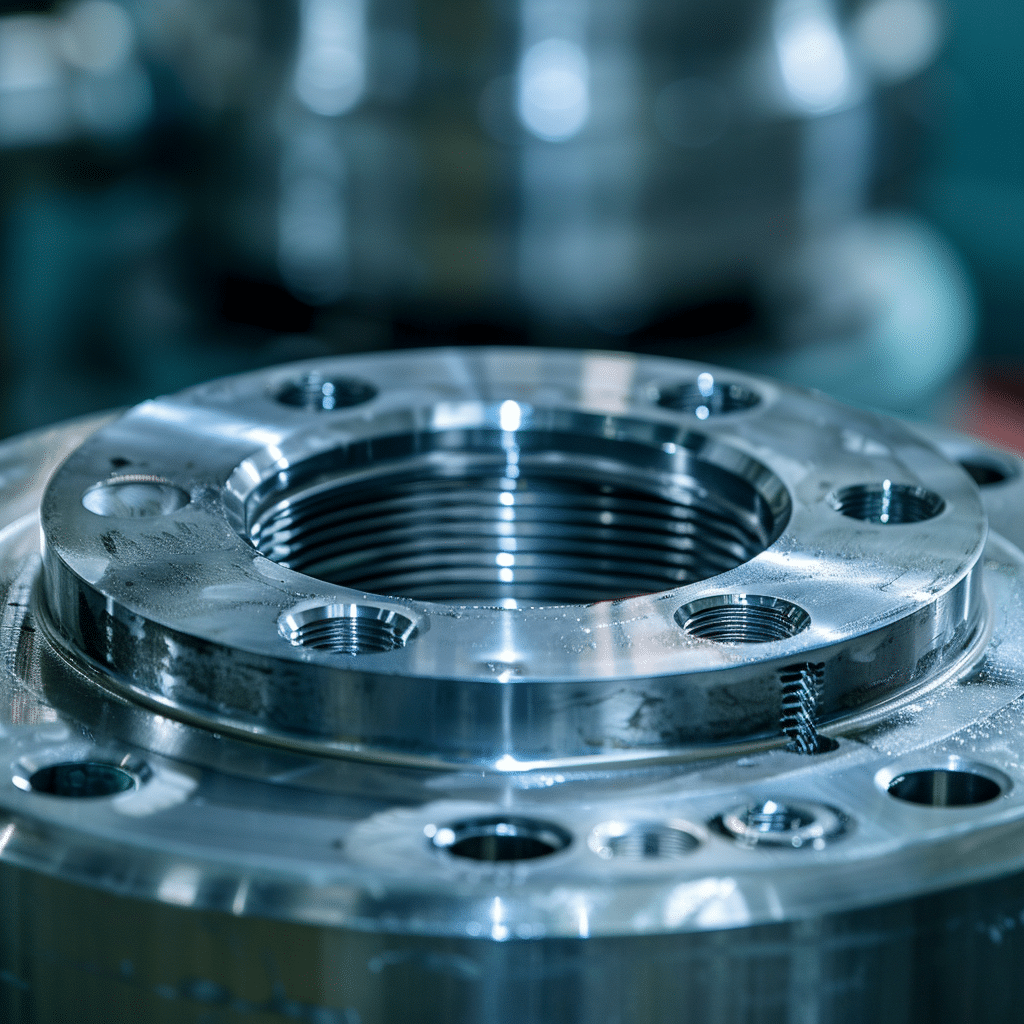

A dry gas seal keeps its faces separated using the same principle that makes a hovercraft float. The rotating seal face has tiny spiral grooves machined into it, typically 10 to 16 grooves with depths between 5 and 6 micrometers. These grooves act like tiny pumps.

Step 1: Gas enters the grooves

When the compressor shaft rotates, gas flows into the spiral grooves machined on the rotating face. The grooves are angled to direct this gas inward toward the center of the seal.

Step 2: Pressure builds at the sealing dam

As gas gets pushed toward the center, it hits a flat section called the sealing dam. This dam acts like a restriction, blocking the gas from escaping easily. The result? Pressure builds up in this area.

Step 3: The seal faces lift apart

That built-up pressure creates an opening force strong enough to push the stationary ring away from the rotating ring. The gap between them stabilizes at around 3 microns during normal operation. That’s about 25 times thinner than a human hair.

Step 4: Equilibrium is reached

The seal finds a sweet spot where the gas pressure pushing faces apart exactly balances the spring force and process pressure pushing them together. This happens automatically as shaft speed and pressure change.

What makes this clever is that the seal adjusts itself. Speed up the shaft, and more gas gets pumped into the grooves, creating more lift. The gap increases just enough to compensate. It’s a self-regulating system that’s been the industry standard for centrifugal compressors since field applications began in the 1970s.

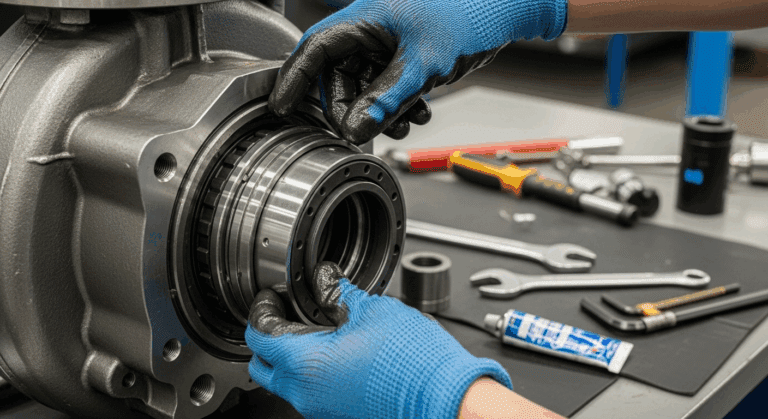

How Does a Wet Seal Maintain Its Liquid Film?

Wet seals work on a completely different principle. They rely on a thin liquid film to keep the seal faces lubricated, cooled, and separated.

Step 1: Springs push the faces together

A set of springs constantly pushes the rotating seal face toward the stationary face. Without any liquid present, these faces would touch and wear out quickly.

Step 2: Liquid creates hydraulic lift

The pumped fluid or an external barrier fluid flows between the seal faces. This liquid creates a thin film, typically about 1 micron thick. The pressure in this film pushes the faces slightly apart.

Step 3: Balance is maintained

The spring force pushing faces together and the fluid pressure pushing them apart reach equilibrium. The gap is incredibly small, about 75 times narrower than a human hair, but it’s enough to prevent direct contact under normal operation.

Step 4: Continuous lubrication and cooling

That liquid film does triple duty. It lubricates the seal faces to reduce friction. It cools the faces by carrying away heat. And it provides a barrier that prevents the pumped product from leaking to atmosphere.

There’s an important distinction here. In single wet seals, the process fluid itself provides that lubricating film. In dual seal arrangements, a separate barrier fluid, pressurized higher than the process, creates an extra layer of protection. This matters a lot when you’re handling toxic or hazardous chemicals.

What Are the Key Performance Differences?

| Factor | Dry Gas Seal | Wet Seal |

|---|---|---|

| Power consumption | About 5 kW per hour | Up to 100 kW per hour |

| Emissions | 6 cubic feet per minute | 40-200 cubic feet per minute |

| Typical lifespan | 10-15 years | Around 5 years |

| Initial cost | Higher | Lower |

| Maintenance frequency | Less frequent | Regular monitoring needed |

| Contamination tolerance | Low (requires clean gas) | Higher |

When Should You Choose a Dry Gas Seal?

Dry gas seals have become the industry standard for centrifugal compressors for good reason. They’re the right choice when you’re handling:

- Centrifugal compressors in natural gas service where emissions reduction matters and clean gas is available

- High-speed rotating equipment since the non-contacting design eliminates wear at any shaft speed

- High-temperature and high-pressure gas applications where wet seals struggle to maintain adequate barrier fluid properties

- Pipelines, refineries, and petrochemical plants that need to meet strict emissions regulations

- Carbon capture and CO2 compression applications, an increasingly important use case

The key advantage is reliability in continuous, high-speed operation. When you need a compressor running 24/7 for years with minimal intervention, dry gas seals deliver.

When Should You Choose a Wet Seal?

Wet seals remain the better choice for several specific situations:

- Centrifugal pumps handling liquids: Pumps in water treatment, chemical processing, and oil transfer are natural fits for wet seals. The process fluid itself often provides adequate lubrication.

- Mixers, agitators, and vessels: These lower-speed applications with varying process conditions favor the flexibility of wet seals.

- Dirty, abrasive, or polymerizing fluids: Wet seals handle contaminated products that would destroy a dry gas seal’s precision grooves.

- Hazardous chemical processes: This one surprised me at first. But think about it. If a wet seal fails, hazardous vapors get trapped in the barrier fluid rather than escaping to atmosphere. That’s an important safety advantage.

- Equipment where dry gas conversion isn’t practical: Some older compressor designs simply can’t accommodate dry gas seal cartridges without major modifications.

Making Your Decision

The choice between dry and wet mechanical seals comes down to your specific application:

Choose dry gas seals when you’re running centrifugal compressors, handling clean gas services, facing strict emissions requirements, or prioritizing long-term reliability and low operating costs. Just commit to the gas quality requirements.

Choose wet seals when you’re operating pumps or other liquid-handling equipment, dealing with contaminated or hazardous fluids, working with older equipment designs, or facing budget constraints on initial investment.