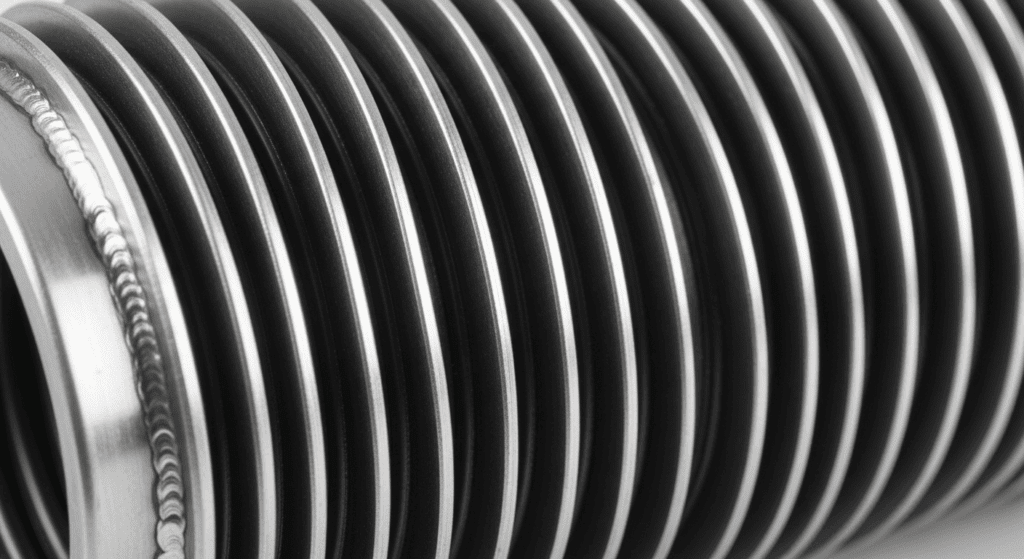

Edge-welded bellows are flexible metal assemblies made by welding thin metal diaphragms together at their edges to create an accordion-like structure. These components serve as dynamic seals and flexible connectors in mechanical systems, allowing movement while maintaining a hermetic barrier that prevents leakage.

Each bellows consists of a series of metal diaphragms welded at their inner and outer edges. Pairs of annular diaphragm plates (typically one male/convex and one female/concave) are welded together at their inside diameter, then joined at the outside diameter to form the complete bellows assembly. This creates a one-piece, leak-tight component capable of elastic movement in axial, lateral, and angular directions.

Types of Bellows Configurations

Standard Single-Ply Configuration

The most common edge-welded bellows design uses a single layer of welded diaphragms. Each convolution consists of one pair of diaphragms welded together, providing a balance of flexibility, pressure capability, and cost-effectiveness for most applications.

Double-Ply (Multi-Ply) Configuration

Double-ply bellows incorporate two concentric layers of diaphragms instead of a single layer. This design significantly enhances pressure capacity and fatigue life without increasing individual layer thickness. The plies share the load and provide redundancy – if one layer develops a crack, the other maintains the seal.

Nested Ripple Design

This configuration features identically contoured diaphragm plates that nest into each other when compressed. The nested design allows maximum stroke in a compact length while achieving a low spring rate and even stress distribution throughout the bellows.

Flat Diaphragm Configuration

Some bellows use flat ring diaphragms rather than contoured shapes. While stiffer and allowing less stroke than nested designs, flat diaphragm bellows provide very linear spring characteristics and can handle higher pressures in certain applications.

Manufacturing of Edge-Welded Bellows

Manufacturing edge-welded bellows requires precision fabrication and specialized welding techniques:

- Diaphragm Stamping: Thin metal sheets (typically 0.001–0.010 inches thick) are stamped or laser-cut into circular diaphragms with complementary male and female shapes designed to create the desired convolution profile.

- Cleaning Process: Diaphragms undergo ultrasonic cleaning to remove contaminants before welding, ensuring optimal weld quality and preventing future leakage.

- Edge Welding: Male and female diaphragm pairs are precisely aligned and welded at the inner diameter using TIG (GTAW), laser welding, or electron beam welding under magnification – a process called microscopic welding due to the small weld size and thin materials.

- Convolution Assembly: Multiple convolution units are stacked and welded together at the outer diameter to form the continuous bellows core, often using removable spacers to ensure uniform spacing and alignment.

- End Fitting Attachment: The bellows ends are welded to flanges or fittings as required for the final application, such as conflat flanges for vacuum systems or seal end pieces for mechanical seals.

- Leak Testing: Complete assemblies undergo helium mass spectrometry or pressure decay testing to verify hermetic sealing, achieving leak rates as low as 1×10^-10 std cc/sec He.

Materials of Edge-Welded Bellows

- Stainless Steels (300-series): 304L, 316L, and 347 SS offer excellent corrosion resistance, good weldability, and maintain ductility at low temperatures.

- AM350 Precipitation-Hardenable Stainless: Provides high tensile strength and hardness when heat-treated, commonly used in mechanical seals and high-pressure applications operating up to 600-700°F.

- Nickel Alloys (Inconel Series): Inconel 625 and 718 are used for high-temperature and high-pressure environments, retaining strength at temperatures above 1000°F while resisting corrosion and oxidation.

- Hastelloy Alloys: Selected for extreme corrosion resistance to aggressive chemicals and acids, particularly valuable in chemical processing where stainless steel would corrode.

- Titanium: Grade 1 or 2 titanium offers lightweight construction with excellent strength-to-weight ratio and superior corrosion resistance, ideal for aerospace, semiconductor, and medical applications.

- Monel: This nickel-copper alloy provides superb resistance to chloride corrosion and salt water, making it valuable for marine and oceanographic equipment.

Mechanical and Performance Characteristics

- Flexibility and Stroke: Edge-welded bellows can compress to “solid height” (fully flattened) without damage, offering stroke-to-length ratios of 85-90%. Multi-convolution designs might compress to just 10-15% of their extended length.

- Spring Rate: The spring rate can be precisely tuned by adjusting diaphragm thickness or convolution count. This low, predictable spring rate makes them ideal for pressure sensors and mechanical seals where minimal force transmission is desired.

- Pressure Capability: Despite thin walls, edge-welded bellows can handle vacuum to over 1000 psi pressure differential. Contoured diaphragm designs distribute stresses effectively, though welded joints remain the limiting factor for ultimate pressure ratings.

- Temperature Range: Operating temperatures span from cryogenic (-252°C/-423°F) to over 1000°F (538°C) for standard materials. Some nickel alloy designs handle up to 1800°F for short durations.

- Cycle Life: Properly designed edge-welded bellows exceed 1,000,000 flex cycles, with precision applications achieving several million cycles when operating within design parameters.

- Leak Tightness: All-welded construction achieves hermetic sealing with leak rates of 1×10^-10 std cc/sec He or better, meeting ultra-high vacuum standards critical for semiconductor and aerospace applications.

Common Applications of Edge-Welded Bellows

- Aerospace and Defense: Used in altitude sensors, fuel system accumulators, pressure regulators, jet engine fuel metering units, and spacecraft propulsion systems where extreme temperature swings and high reliability are essential.

- Semiconductor and Ultra-High Vacuum Systems: Essential components in wafer handling robots, vacuum valve stems, linear actuators, and vacuum feedthroughs where maintaining UHV conditions and cleanliness is critical.

- Medical Devices: Found in implantable drug pumps, artificial heart components, surgical laser equipment, and diagnostic imaging systems requiring biocompatibility and hermetic sealing.

- Industrial Vacuum and Processing: Common in vacuum furnace assemblies, bellows-sealed valves for toxic/corrosive fluids, pressure gauges and transducers for aggressive media, and load cells.

- Mechanical Seals: Serve dual roles as spring and secondary seal in pumps and compressors, ideal for high-temperature applications where elastomer O-rings would fail, eliminating dynamic O-ring hang-up issues.

- Instrumentation and Sensors: Used in differential pressure sensors, volume compensators, and acceleration sensors where predictable effective area and spring rate are crucial for measurement accuracy.

What is the Difference Between Edge-Welded Bellows and Formed Bellows

| Characteristic | Edge-Welded Bellows | Formed Bellows |

|---|---|---|

| Construction Method | Individual diaphragms welded at edges | Single tube hydroformed or mechanically formed |

| Flexibility | Very high; can compress to solid height | Limited by thicker walls; cannot fully compress |

| Spring Rate | Low and precisely tunable | Higher and less adjustable |

| Stroke-to-Length Ratio | Up to 85-90% compression | Typically 30-50% compression |

| Material Options | Wide range including exotic alloys | Limited to ductile, formable materials |

| Temperature Range | Cryogenic to 1800°F with appropriate alloys | Typically -40°F to 500°F |

| Pressure Capability | High with proper design; up to 1000+ psi | Moderate; thick walls needed for high pressure |

| Cycle Life | Often exceeds 1,000,000 cycles | Typically 100,000-500,000 cycles |

| Leak Tightness | Hermetic; achieves UHV standards | Good but potential for micro-cracks |

| Initial Cost | Higher for small quantities | Lower per piece in high volume |

| Customization | Highly customizable | Limited; requires new tooling |

| Best Applications | Critical, high-performance systems | High-volume, moderate-duty uses |