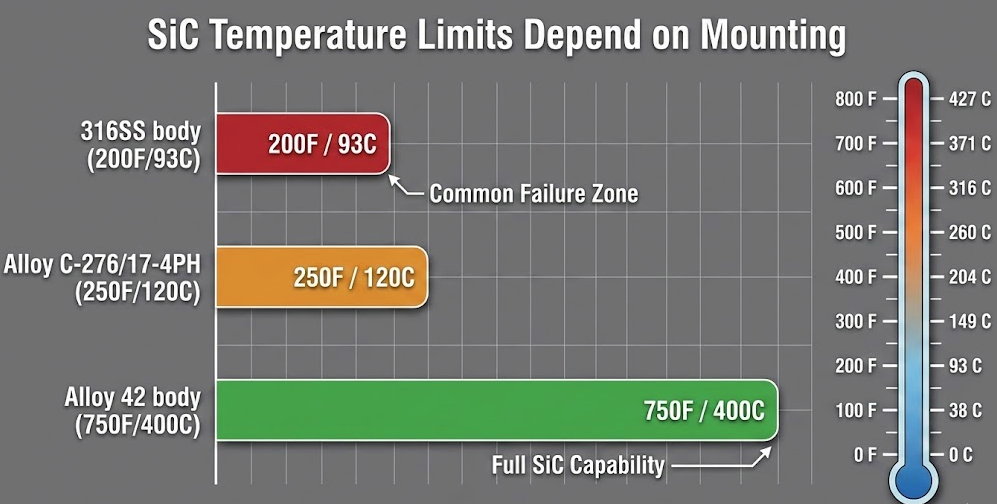

Why does a seal rated to 800F fail at 200F in your boiler feed pump? The answer lies not in the face material specification but in how that material is mounted. A silicon carbide face pressed into a 316 stainless steel holder is limited to 200F (93C)—not because of SiC’s capability, but because differential thermal expansion breaks the interference fit. Mount that same SiC in Alloy 42, and the limit jumps to 750F (400C).

This single distinction—understanding that temperature limits depend on the entire seal assembly rather than just the face material—separates successful BFW seal applications from chronic failures. Boiler feedwater ranks among the most challenging fluids to seal mechanically. The API 682 standard specifies these seals should achieve three years of continuous operation, yet many facilities struggle to reach 12 months.

The challenge stems from BFW’s unique combination of high temperature (100-200C), high pressure (20-200 barg), high shaft speeds (3,600-5,500 RPM), and critically, low lubricity once temperature rises above 65C (150F). At this threshold, water viscosity drops below 0.43 cP, and the fluid film that protects seal faces begins to fail. By 71C (160F), standard seal designs experience complete film breakdown.

Achieving reliable BFW seal performance requires integrating material selection, API piping plans, seal type configuration, and thermal management into a cohesive specification. Each element depends on the others.

The Challenge of Sealing Boiler Feedwater

Boiler feedwater presents a paradox: a seemingly benign fluid that defeats seals rated for far harsher chemicals. As experienced engineers know, when students are asked what the hardest stream to seal is, they rarely get the right answer—water.

The difficulty centers on water’s viscosity behavior at elevated temperatures. At room temperature, water provides adequate lubrication for seal faces. But as temperature increases, viscosity drops exponentially. At 65C (150F), viscosity reaches 0.43 cP—the minimum threshold for maintaining a stable fluid film in most seal designs. This explains why many specifications cite 150F as the boundary requiring thermal management.

Beyond 71C (160F), the fluid film in standard seals fails entirely. The seal faces transition from hydrodynamic lubrication to boundary lubrication, dramatically increasing heat generation and wear rates. Without intervention, this triggers a failure cascade: increased friction generates more heat, further reducing viscosity, which accelerates wear.

The operating envelope compounds this challenge. BFW pumps typically operate at:

| Parameter | Typical Range | Impact on Seal Selection |

|---|---|---|

| Pressure | 20-200 barg (290-2,900 PSIG) | Requires balanced seal design above 200 PSIG |

| Temperature | 100-200C (212-392F) | Demands thermal management and appropriate materials |

| Shaft Speed | 3,600-5,500 RPM | Increases heat generation and PV value |

| Flow Requirement | 8-40 L/min (2-10 GPM) | Minimum circulation for Plan 23 systems |

| Heat Transfer | 5-25 kW (17,000-85,000 BTU/hr) | Sizing requirement for heat exchangers |

These conditions eliminate many seal configurations. High pressure rules out metal bellows designs in most applications. High temperature limits elastomer choices. High speed increases heat generation. The combination demands careful integration of every selection criterion.

Material Selection for High-Temperature BFW Service

Face material selection determines maximum operating temperature—but the spec sheet temperature rating tells only part of the story. The mounting configuration determines actual service limits.

Face Materials

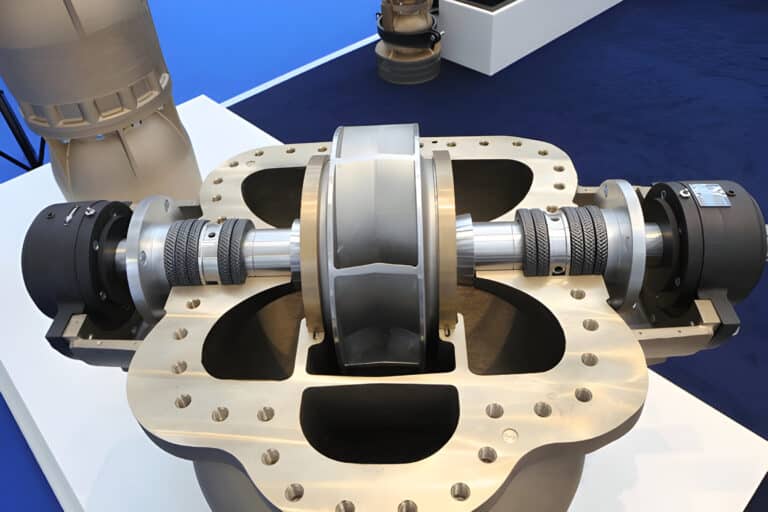

Silicon carbide (SiC) delivers the best performance in BFW service due to its thermal conductivity (120-170 W/mK), which dissipates heat faster than alternatives. Its low thermal expansion coefficient (4.0-4.5 x 10^-6/C) provides dimensional stability through temperature fluctuations.

The critical distinction lies in mounting configuration:

| SiC Mounting | Max Temperature | Explanation |

|---|---|---|

| In 316SS body | 200F (93C) | Thermal expansion mismatch loosens press fit |

| In Alloy C-276 or 17-4PH | 250F (120C) | Moderate improvement |

| In Alloy 42 body | 750F (400C) | Matched expansion coefficient |

This variance explains a common failure pattern. Engineers specify SiC for high-temperature service based on the material’s intrinsic capability (800F+), then experience failures at 200F because the seal uses a standard 316SS holder. The spec sheet may not highlight this limitation.

Tungsten carbide (TC) offers an alternative with 84-100 W/mK thermal conductivity and greater fracture toughness than SiC. However, its higher thermal expansion (5.0-6.0 x 10^-6/C) makes it less suitable for thermal cycling applications.

Carbon graphite serves as the mating face material. Standard grades reach 500F (260C); API-grade antimony-filled carbon extends this to 700F (370C). For applications exceeding elastomer limits, the carbon face may become the temperature-limiting component.

Secondary Seal Materials

Elastomeric O-rings represent the weakest link in most BFW seal assemblies:

| Material | Max Temperature | BFW Suitability |

|---|---|---|

| EPDM (peroxide cured) | 300F (150C) | Good for moderate temperatures |

| FKM (Viton) | 400F (204C) | Limited chemical resistance to steam |

| FFKM (Kalrez 7075) | 620F (327C) | Highest-temperature elastomer |

| Grafoil (flexible graphite) | 850F (454C) | Non-elastomeric, used in Type C seals |

For temperatures exceeding 350F, flexible graphite secondary seals (Grafoil) eliminate the elastomer limitation entirely. API 682 Type C seals use this approach to achieve 750F capability.

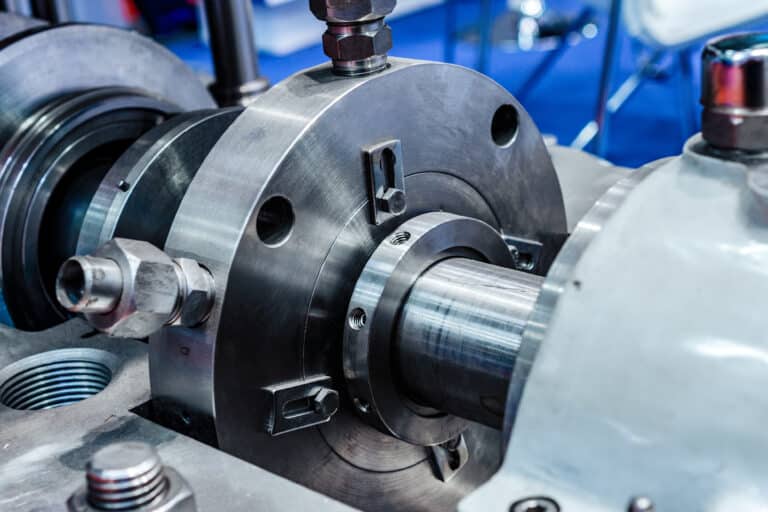

Seal Face Flatness Requirements

Temperature fluctuations stress seal faces, making initial flatness critical. Hard face material combinations require:

| Material | Flatness | Surface Finish |

|---|---|---|

| Silicon Carbide | 1-2 light bands (0.3-0.6 um) | 0.04 um RMS |

| Tungsten Carbide | 1-2 light bands (0.3-0.6 um) | 0.01 um RMS |

| Carbon/Graphite | 2-3 light bands (0.6-0.9 um) | 0.1 um RMS |

At pressures above 40 bar (580 PSIG), tighten flatness requirements to 1 light band regardless of material.

API 682 Seal Type and Category Selection

The API 682 standard provides a framework for mechanical seal selection that directly addresses BFW applications. Understanding type and category designations simplifies specification.

Seal Types by Temperature Range

| Type | Description | Temperature Limit | Secondary Seals |

|---|---|---|---|

| Type A | Balanced cartridge pusher seal with multiple springs | 350F (176C) | Elastomeric O-rings |

| Type B | Balanced cartridge metal bellows seal | 350F (176C) | Elastomeric O-rings |

| Type C | Balanced cartridge high-temp metal bellows | 750F (400C) | Flexible graphite |

Type A (pusher) seals dominate BFW applications despite the apparent advantage of Type B metal bellows. The reason: pressure capability. As noted in industry literature, the operating pressure at the mechanical seal location typically eliminates the ability to use metal bellows mechanical seals.

Metal bellows seals typically limit to 300-500 PSI, while BFW pump seal chambers commonly exceed this. A pusher seal with proper thermal management through Plan 23 handles both the pressure and temperature requirements.

Type C seals become necessary when BFW temperatures exceed 350F (176C). The flexible graphite secondary seals eliminate elastomer temperature limitations, extending capability to 750F. However, Type C seals cost significantly more than Type A configurations.

Seal Categories by Application

| Category | Intended Application | Temperature Range | Pressure Limit |

|---|---|---|---|

| Category 1 | Non-API-610 pumps | -40 to 500F | 315 PSI (22 bar) |

| Category 2 | API-610 pumps | -40 to 750F | 615 PSI (42 bar) |

| Category 3 | Most rigorous testing/documentation | -40 to 750F | 600 PSI (40 bar) |

For BFW pumps meeting API-610 standards, Category 2 or 3 seals match the pump’s quality level. Category 3 provides the most extensive testing documentation—valuable for critical service or when troubleshooting historical failures.

Balanced vs Unbalanced Seal Selection

Seal balance ratio determines face loading and directly impacts heat generation—critical in a service where thermal management is already challenging.

Balance Ratio Specifications

A balanced seal reduces the hydraulic closing force acting on seal faces by modifying the effective area ratio. Standard specifications:

| Service | Balance Ratio | Application |

|---|---|---|

| Water and non-flashing hydrocarbons | 0.75 | Standard BFW service |

| Flashing hydrocarbons | 0.80-0.85 | High vapor pressure fluids |

| Unbalanced reference | 1.10-1.60 | Not suitable for high-pressure BFW |

The 0.75 balance ratio for water service reduces face loading to 75% of what an unbalanced seal would experience at the same pressure. This translates directly to heat generation: balanced seals generate 30-40% less friction heat than unbalanced designs.

Pressure Thresholds

Unbalanced seals are limited to approximately 16 bar (232 PSI). Above 200 PSIG, balanced seals become recommended; above 500 PSIG, they are mandatory for BFW service.

BFW pumps routinely operate at seal chamber pressures well above these thresholds. Seal chamber pressure varies by pump configuration:

| Pump Type | Seal Chamber Pressure |

|---|---|

| OH2 (overhung) | Suction + 15% of differential |

| BB (multistage) | Approximately suction pressure |

| VS (vertical) | Approximately discharge pressure |

| With balance holes | Near suction pressure |

For a multistage BFW pump with 500 PSIG suction and 2,000 PSIG discharge, the seal chamber on the high-pressure end may see 700+ PSIG without a balance line—far exceeding unbalanced seal limits.

API Piping Plan Selection with Lifecycle Cost Analysis

The piping plan determines seal face temperature regardless of material selection. For high-temperature seal selection, Plan 23 has become the standard for BFW applications—and lifecycle cost analysis explains why.

Plan Comparison

| Plan | Operating Principle | Annual Cost | Heat Soak |

|---|---|---|---|

| Plan 21 | Recirculation from discharge through cooler | $24,640 | 86.3 kW |

| Plan 23 | Closed loop thermosyphon with heat exchanger | $2,170 | 4.4 kW |

| Plan 32 | External cool water injection | $12,213 | 42 kW |

Data from the Fluid Sealing Association’s Life Cycle Cost Estimator demonstrates the dramatic difference. Plan 23 reduces annual operating costs by 91% compared to Plan 21—saving approximately $22,470 per seal per year.

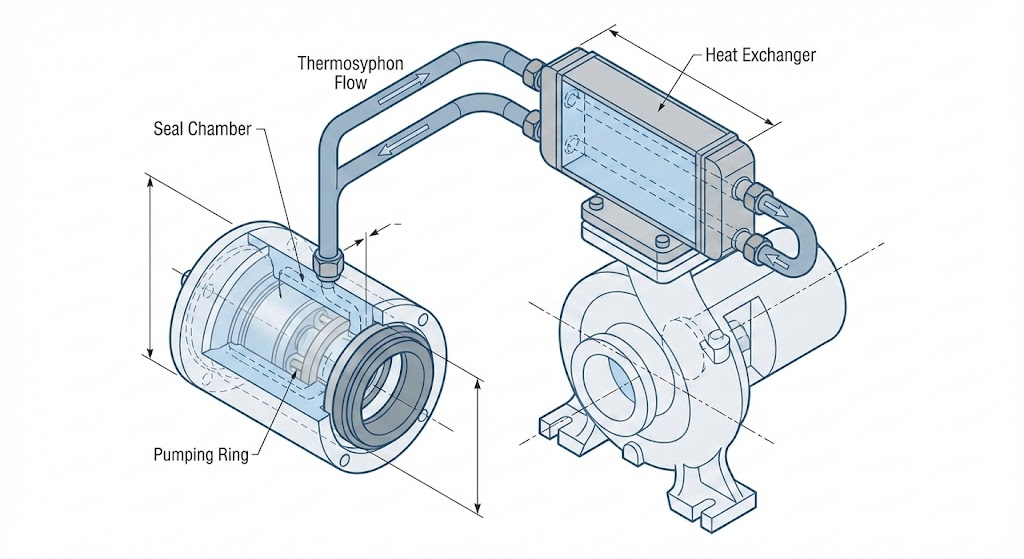

The cost difference stems from heat soak. Plan 21 requires continuous flow from pump discharge through a cooler, dumping 86.3 kW of thermal energy that must be removed by cooling water. Plan 23’s closed-loop design with a pumping ring circulates only the seal chamber inventory, reducing heat load to 4.4 kW—a 95% reduction.

Plan 23 Installation Requirements

Thermosyphon circulation depends on proper heat exchanger placement:

| Parameter | Specification | Source |

|---|---|---|

| HX height | 500 mm above pump centerline | EagleBurgmann |

| Tubing | Smooth, continuously rising, avoid sharp bends | Standard practice |

| Vent valve | Required at highest point before startup | Standard practice |

| Return temperature target | Below 130F (54C) | Industry practice |

A functional Plan 23 system should return cooled fluid to the seal chamber below 130F (54C). If monitoring shows higher return temperatures, the heat exchanger is undersized or fouled.

When Plan 32 Makes Sense

Plan 32 (external clean water injection) offers a middle ground at $12,213/year. The lower flow rate and direct cooling achieve better thermal performance than Plan 21. However, Plan 32 introduces external fluid that dilutes the boiler feedwater—a concern in applications requiring strict water chemistry control.

For facilities where water chemistry permits dilution and a reliable external water source exists, Plan 32 provides simpler installation than Plan 23 at moderate cost.

Managing Thermal Cycling and Startup Conditions

BFW pumps that cycle frequently face additional challenges. Thermal shock during cold starts stresses every seal component—faces, elastomers, metal parts, and the interference fits holding everything together.

Thermal Shock Mechanisms

During a cold start, hot feedwater flows into a cold pump. Inner components heat faster than the pressure boundary. Temperature gradients create several failure mechanisms:

Seal Face Effects:

- Thermal deformation causing uneven wear patterns

- Thermal cracking in brittle materials (SiC more susceptible than TC)

- Concave or convex face distortion affecting film stability

Elastomer Effects:

- Thermal shock hardening

- Compression set acceleration

- Cracking at stress concentration points

System Effects:

- Increased wear ring clearances

- Potential pump seizure

- Internal rubbing damage

The frequency of cycling matters as much as temperature differential. A pump starting cold twice daily accumulates more thermal fatigue than one running continuously at higher temperature.

Design Solutions for Thermal Management

Eight approaches address thermal cycling:

- Prewarming – Essential for maintaining internal clearances. Warm the pump before introducing full-temperature feedwater.

- Warmup flow – Maintain continuous low flow to idle pumps, ensuring dimensional thermal uniformity before startup.

- Thermal separation – Use an insulation chamber system to thermally isolate the seal area from hot fluid.

- External insulation – Insulate pump exterior to slow heat loss during standby.

- Hot standby operation – Keep boiler feedwater near operating temperature with continuous recirculation.

- Temperature monitoring – Install thermocouples in pump casing and discharge head. Confirm temperature differences stay within 50F (28C) before starting.

- Warmup orifice – Pipe around the discharge check valve to maintain warmup flow.

- Turning gear – Rotate the pump in standby mode to minimize thermal distortion from temperature stratification.

Seal Drain Temperature Control

For best mechanical seal flushing performance in high-temperature service, maintain shaft seal leakage drain temperature between 150F and 170F (65C and 77C). This requires an electro-pneumatic temperature control system that modulates cooling based on actual drain temperature.

Material Selection for Cycling Service

When thermal cycling cannot be avoided, material selection shifts:

- Prefer SiC over TC – Better thermal shock resistance due to higher thermal conductivity and lower expansion

- Consider graphite-loaded SiC – Improved performance in low-lubricity conditions during warmup

- Select peroxide-cured EPDM – Better retention of properties through temperature cycling than FKM

- Evaluate metal bellows with Grafoil – Eliminates elastomer degradation concern entirely if pressure permits

Synthesis: Integrating Selection Criteria

Selecting mechanical seals for boiler feedwater service requires balancing interconnected criteria. No single factor dominates—temperature, pressure, shaft speed, and operating pattern must all align with the seal configuration.

For temperatures below 350F with operating pressures above 300 PSI: Type A balanced pusher seals with Plan 23 thermal management provide the most reliable configuration. Specify SiC faces mounted in appropriate holder material (Alloy 42 for temperatures approaching 350F). Use FFKM secondary seals for maximum margin.

For temperatures between 350F and 750F: Type C balanced metal bellows seals with flexible graphite secondary seals become necessary. Plan 23 remains the preferred thermal management approach, though heat exchanger sizing must account for the higher temperature differential.

For all BFW applications: Balance ratio of 0.75, Plan 23 with return temperature monitoring, and attention to thermal cycling if the pump does not run continuously.

The API 682 objective of 25,000 operating hours (three years) is achievable in BFW service. Facilities that integrate seal material selection, appropriate seal type, proper piping plan, and thermal management routinely exceed this target—some by factors of two or more.

The investment in proper specification pays returns immediately through reduced maintenance, fewer unplanned shutdowns, and lower operating costs. Plan 23 alone saves over $22,000 annually compared to Plan 21 on a single pump. Extended seal life multiplies these savings while improving plant reliability.