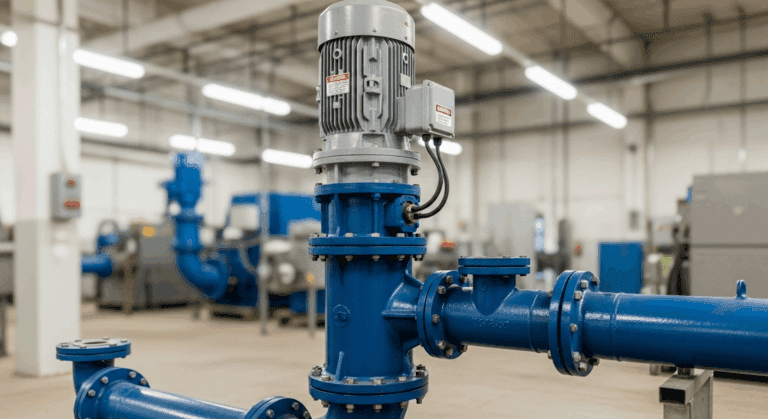

The machinery industry faces a challenge in selecting the correct packing size for stuffing boxes. Inaccurate measurements can lead to leaks, equipment damage, and costly downtime.

Improperly sized packing can cause excessive friction, overheating, and premature wear on shafts and sleeves. It can also allow process fluids to escape, posing safety hazards and environmental risks.

This guide provides step-by-step instructions for measuring stuffing boxes and selecting the optimal packing size, ensuring reliable sealing and extending equipment life. By following these best practices, machinery professionals can improve operational efficiency and reduce maintenance costs.

Measuring the Stuffing Box

Inside Diameter of the Stuffing Box

Measure the inside diameter of the stuffing box bore using a caliper or bore gauge. Take measurements at several points around the circumference and average them for the most accurate result.

Depth of the Stuffing Box

Using a depth micrometer or depth gauge, measure the distance from the stuffing box face to the bottom of the bore.

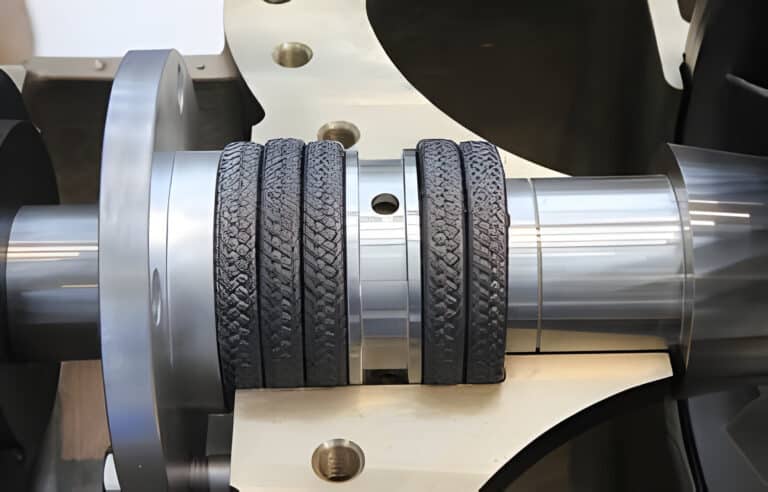

Diameter of the Shaft

Accurately measure the outside diameter of the shaft where it passes through the stuffing box. Use a micrometer or caliper and take measurements at several points to account for any out-of-roundness.

Flush Hole Measurements

If the stuffing box incorporates flush holes, measure and record the following:

- Flush Hole Diameter: Measure the diameter of each flush hole using a caliper or gauge pin.

- Flush Hole Location: Note the axial position of the flush holes relative to the stuffing box face. This affects the placement of lantern rings or throat bushings, if used.

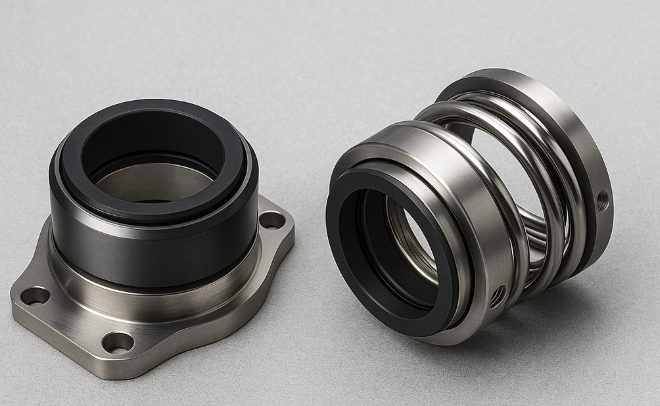

Selecting the Correct Packing Size

With the stuffing box and shaft dimensions known, the appropriate packing cross-sectional size can be determined:

- Subtract: Subtract the shaft diameter from the inside diameter of the stuffing box.

- Divide: Divide the result by 2. This gives you the required packing size.

For example, if the stuffing box inside diameter measures 2.500 inches and the shaft diameter is 2.000 inches:

2.500″ – 2.000″ = 0.500″

0.500″ / 2 = 0.250″ (1/4″ packing size)

Common Sizing Chart

| Shaft Size | Suggested Packing Size | Approximate Packing Needed (inches) |

|---|---|---|

| 3/4″ | 3/8″ | 17 |

| 7/8″ | 5/16″ | 22 |

| 1″ | 1/4″ | 28 |

| 1 1/8″ | 3/16″ | 33 |

| 1 1/4″ | 1/4″ | 39 |

| 1 3/8″ | 5/16″ | 44 |

| 1 1/2″ | 1/4″ | 50 |

| 1 3/4″ | 1/2″ | 55 |

| 2″ | 3/8″ | 63 |

| 2 1/8″ | 3/8″ | 69 |