When your mechanical seal fails in corrosive service, what failed first – the silicon carbide face or the O-ring? Most engineers assume the face materials matter most. After ten years of field service, I’ve learned the opposite: elastomers often fail before face materials in corrosive applications. That FFKM O-ring you specified? In chlorine service, it can degrade within weeks.

The common approach – obsessing over SiC versus tungsten carbide while treating elastomer selection as an afterthought – leads to preventable failures. This guide provides a selection framework that prioritizes the right component for each chemical category.

Why Elastomers Often Fail Before Face Materials

Elastomers degrade through chemical attack on their polymer structure, while ceramic and carbide faces resist most chemicals through sheer inertness. The difference in failure speed is dramatic.

In one chlorine processing unit, FFKM O-rings – supposedly the “universal” elastomer degraded within weeks. The seal faces showed minimal wear. The expensive perfluoroelastomer simply couldn’t handle the specific chlorine concentration and temperature combination.

The most common mistake I see is engineers spending hours comparing face materials while barely glancing at elastomer compatibility. Consider ammonia service: according to the IPEX Chemical Resistance Guide, EPDM rates 1 (excellent) while FKM (Viton) rates 4 (not recommended). Yet FKM remains the default choice in many specifications because “it’s what we always use.”

Elastomer failure is typically faster and more catastrophic than gradual face wear. A face might degrade over months; an incompatible elastomer can swell, crack, or dissolve in days.

FKM Limitations You Need to Know

FKM (Viton) is the default elastomer for chemical service – API 682 specifies it as the Type A seal standard. But that default can become a liability in several common applications.

Steam and Hot Water

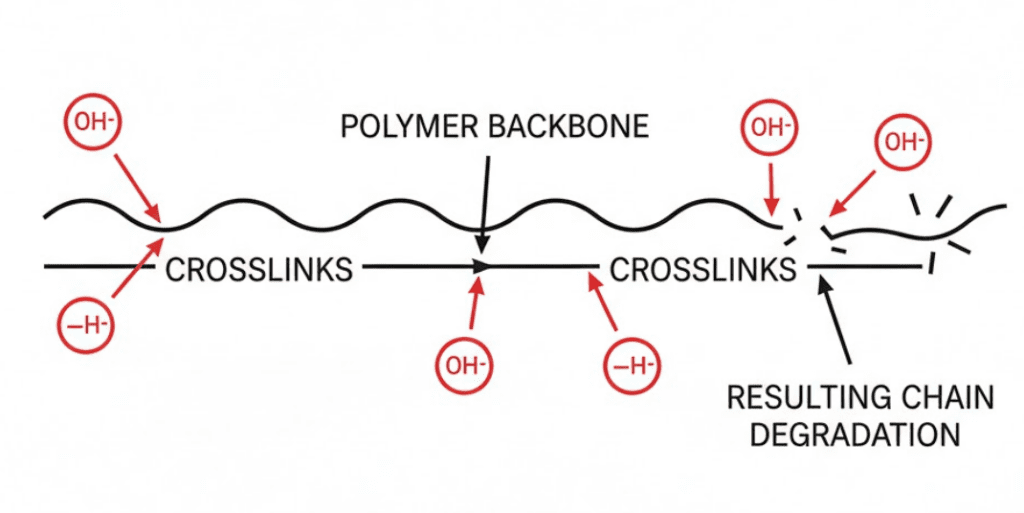

Standard bisphenol-cured FKM deteriorates in hot water and steam through hydrolysis. As engineers on technical forums have documented, hot water has a high concentration of OH- radicals that attack the crosslinks in the polymer chain. The elastomer softens, swells, and eventually fails.

If you skip this consideration, you’ll be back replacing that seal within months. For steam or hot water above 180F, specify peroxide-cured FKM variants or switch to EPDM entirely.

Ammonia and Amines

Ammonia, ethylenediamine, and other amine-based chemicals react aggressively with FKM. The ammonia rating comparison tells the story: EPDM performs excellently where FKM fails completely.

Before you start specifying seals for ammonia refrigeration or amine processing, make sure you’ve switched from FKM to EPDM. The cost difference is negligible; the reliability difference is enormous.

Strong Bases and Alkalis

Caustic soda, potassium hydroxide, and similar strong bases attack FKM through the same hydrolysis mechanism as steam. For pH levels above 11, FKM becomes unreliable.

The alternative? EPDM handles most bases well. For extreme cases, Aflas (FEPM) offers excellent resistance to both acids and bases – a rare combination.

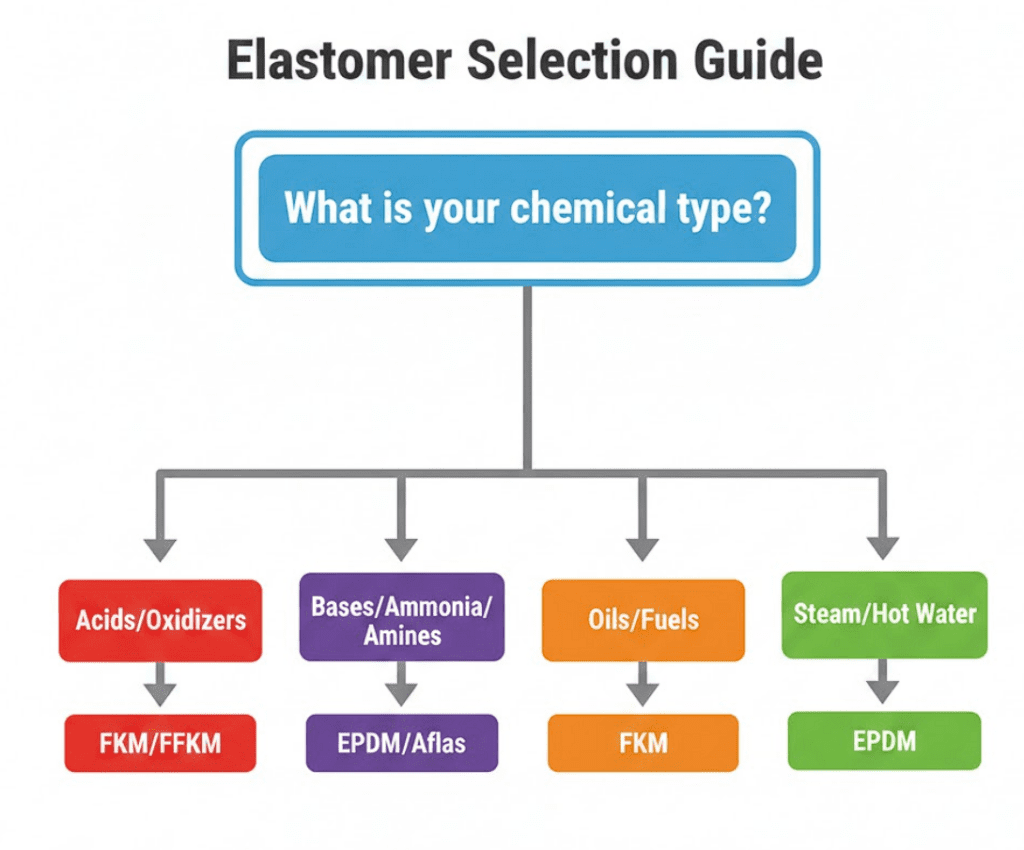

Elastomer Selection by Chemical Category

Matching the elastomer to your specific chemical delivers better results than defaulting to the most expensive option. FFKM costs more than ten times what FKM costs, but throwing money at the problem doesn’t guarantee success.

Acids and Oxidizers

FKM handles most mineral acids and oxidizing chemicals well. Sulfuric, nitric, and phosphoric acids at moderate concentrations and temperatures work fine with standard FKM.

For concentrated acids or elevated temperatures, FFKM becomes necessary. But verify the specific acid – some attack even FFKM.

Bases, Ammonia, and Amines

This is where the conventional wisdom fails. FKM versus EPDM isn’t a close call for base service – EPDM wins decisively.

For ammonia refrigeration, caustic processing, or amine service, specify EPDM. For applications requiring both acid and base resistance (rare but they exist), Aflas handles both categories.

Oils and Fuels

FKM excels here. Hydrocarbon resistance is FKM’s core strength, with excellent performance against oils, fuels, and most petroleum products.

EPDM fails completely with hydrocarbons – it swells rapidly and loses all sealing capability. Never use EPDM in oil service.

Steam and Hot Water

EPDM is the clear choice for saturated steam and hot water applications. Standard FKM degrades through hydrolysis; peroxide-cured variants improve performance but still lag behind EPDM.

Remember the temperature rule: chemicals become approximately twice as aggressive for every 20-degree rise in temperature. That “warm” water at 200F attacks elastomers far more aggressively than the same water at 100F.

Face Material Selection for Corrosive Service

Once you’ve sorted the elastomer, face materials become the second priority. The good news: mechanical seal face materials generally resist corrosion better than elastomers, but they’re not immune.

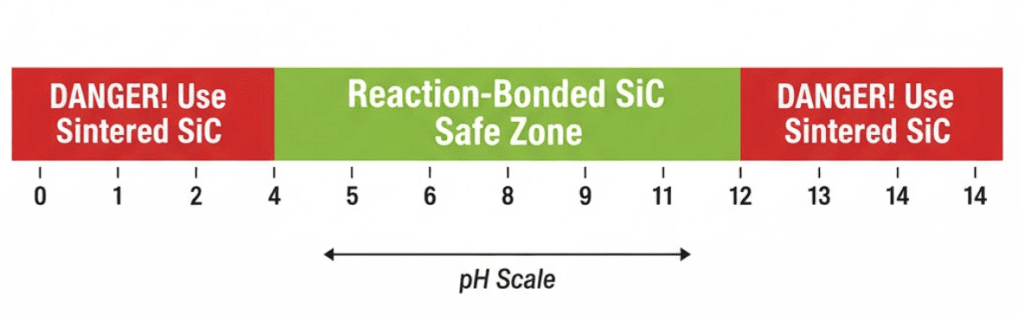

Silicon Carbide Types

Not all silicon carbide is equal. Reaction-bonded SiC contains free silicon, which limits chemical resistance. Avoid reaction-bonded SiC in applications with pH below 4 or above 11.

Direct-sintered silicon carbide offers superior chemical resistance across a much wider pH range. For aggressive chemical service, always specify sintered SiC over reaction-bonded.

Carbon Graphite

Carbon-graphite faces offer broad chemical compatibility but sacrifice hardness. They work well as the softer face in a hard-soft pairing, particularly in clean services without abrasives.

For most corrosive applications without significant abrasives, carbon against sintered SiC provides a reliable combination.

Tungsten Carbide

Tungsten carbide uses a cobalt or nickel binder that limits chemical resistance compared to SiC. In strong acids or bases, the binder can leach out, leaving a weakened structure.

For highly corrosive applications, sintered silicon carbide generally outperforms tungsten carbide. Reserve WC for applications where its superior impact resistance outweighs chemical resistance concerns.

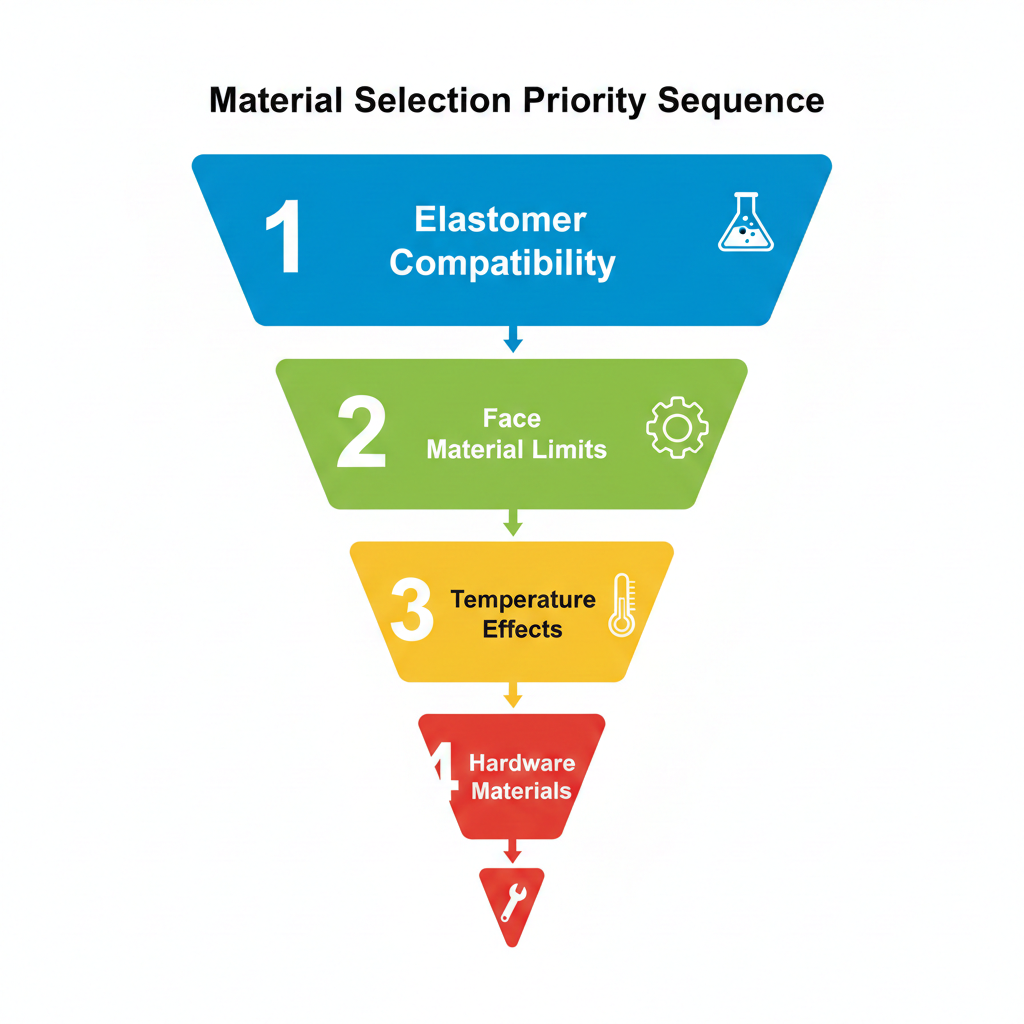

Selection Priority Sequence

Here’s the process I recommend for every corrosive media application:

- Check elastomer compatibility first. Identify the process chemical and verify elastomer ratings. If FKM is marginal or unsuitable, select the appropriate alternative before considering anything else.

- Verify face material limits. Check pH range and specific chemical compatibility. For pH extremes, specify sintered SiC over reaction-bonded.

- Factor in temperature. Whatever your chemical resistance data shows at ambient temperature, assume it gets worse as temperature rises. Add safety margin or upgrade materials accordingly.

- Consider hardware last. Springs, metal components, and housings usually pose fewer problems than elastomers and faces in corrosive service, but verify compatibility for highly aggressive chemicals.

Making the Right Choice

The elastomer is usually the weakest link in corrosive service. A systematic approach – checking elastomer compatibility before face materials, matching to chemical category rather than defaulting to premium options – prevents most material-related failures.

For complex applications with multiple chemicals or extreme conditions, consult your seal manufacturer with complete process data. But for most corrosive services, getting the elastomer right solves eighty percent of the material selection challenge.