One in five mechanical seal failures traces directly back to installation errors. That statistic comes from Plant Engineering research, and it represents the most preventable category of seal failures in power plant operations. Before you blame the seal supplier or the process conditions, look at what happened during the last installation.

Power plant pumps operate under conditions that expose every installation shortcut. Continuous duty means your boiler feed pumps run 8,760 hours per year with no downtime to hide problems. High temperatures in the 300-400F range stress every component. The stakes are equally high – an unplanned pump shutdown can mean significant lost generation revenue and emergency repair costs.

Most power plant seal failures are preventable. Pre-installation verification – checking shaft runout, inspecting the seal chamber, confirming flush system operation – catches the majority of problems before you ever start the pump. A US nuclear power plant proved this: they went from a 50/50 chance of excessive leakage upon startup to nearly two years of leak-free operation. The difference was not a better seal design. It was better installation verification.

Why Pre-Installation Verification Matters for Power Plants

If your mechanical seal mean time between failures (MTBF) is below 12 months, you have an installation problem, not a seal problem. As William Forsthoffer notes in Turbomachinery Magazine, “Failure to have and implement a required mechanical seal installation procedure has been a principal cause of low mechanical seal MTBFs (lower than 12 months).”

Power plant environments differ from general industrial applications in ways that matter for seal installation. Your boiler feed pumps run continuously – no weekends off, no seasonal shutdowns. Thermal cycling from load changes stresses seal faces and secondary sealing elements repeatedly. Generic manufacturer recommendations assume intermittent duty; power plants need tighter practices.

The most common mistake I see is rushing past pre-installation checks. Teams replace a failed seal with an identical new one, skip the verification steps, and restart the pump – then wonder why the new seal fails in three months. Henri Azibert and William Burke quantified this in their Plant Engineering analysis: poor installation accounts for up to 20% of seal failures, even with modern cartridge seal designs.

If you skip pre-installation verification, you will likely be back replacing that seal sooner than the manufacturer MTBF suggests. The time invested upfront pays back in avoided emergency repairs.

Shaft and Alignment Verification

Shaft runout is your first checkpoint. Radial runout should be below 0.002 to 0.005 inches (0.05-0.13 mm) for standard power plant pump speeds. For high-speed pumps running faster than 3,600 RPM, the tolerance tightens to 0.001 to 0.002 inches. Excessive runout causes the seal faces to separate unevenly during rotation, creating leak paths and accelerating wear.

Measure shaft runout before seal installation using a dial indicator at multiple points along the shaft where the seal components will ride. Document your readings. If runout exceeds tolerance, address it before proceeding – installing a new seal on a bent shaft guarantees premature failure.

Seal chamber face flatness matters equally. The total indicator reading (TIR) on the seal chamber face should be no more than 0.005 inches. This ensures the stationary seal face seats properly against the chamber. Warped or corroded seal chambers cause cocked seal faces that leak from day one.

Pump and motor alignment directly affects seal life. Target alignment tolerance of 0.001-0.002 inches between pump and motor shafts. Misalignment transmits forces through the coupling to the pump shaft, causing the rotating seal face to wobble rather than run true.

A case study from Crane Engineering illustrates this perfectly. An ammonia pump with a Goulds 3196 failed within one year. Root cause analysis revealed significant shaft misalignment that laser alignment could have detected. The report noted: “Replacing the seal would only be a temporary solution, as the worn components directly impact the overall reliability of the seal.” A pre-installation alignment check would have caught this issue before the new seal was installed.

Seal Chamber and Component Inspection

Surface finish on the shaft where secondary sealing elements ride should be maximum 32 rms (microinches). Scratches, corrosion pits, or machining marks create leak paths past O-rings and bellows. Run your finger along the shaft surface – if you can feel imperfections, the seal can too.

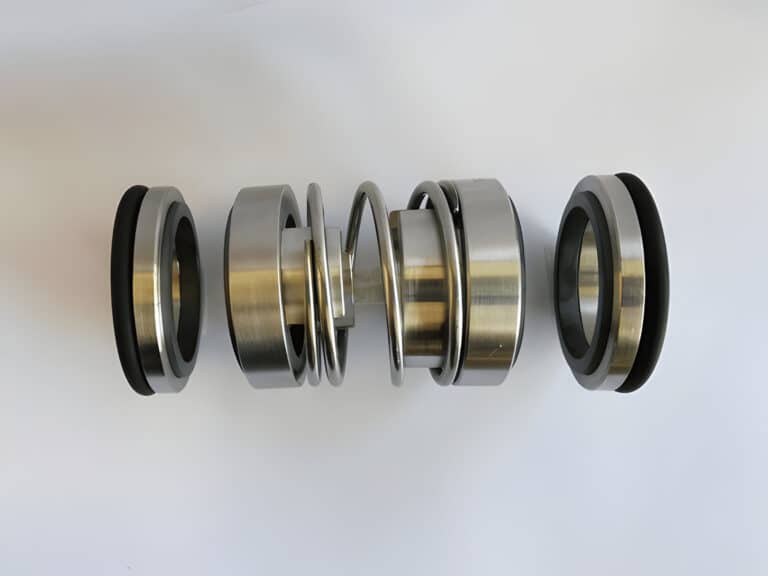

Seal face flatness is measured in helium light bands – within 1-2 light bands means the faces are flat to within approximately 0.6 micrometers. Faces lapped within one micron of flatness create the precision seal that keeps your pump running. Never install a seal with visible scratches or handling marks on the faces; even fingerprints leave oils that can affect sealing.

The Oceaneering North Sea study examined 40 production pumps with repeated premature seal failures. Their root cause analysis found 12 contributing factors, with installation variance among offshore maintenance teams topping the list. Other findings included incomplete venting during startups, barrier fluid contamination during tank refilling, and missing maintenance plan tasks. Every one of these issues could have been caught through proper installation procedures and verification.

A US nuclear power plant intake station provides an even more striking example. Their Worthington 6LR-16 pumps used a four-piece split seal plus packing combination that leaked chronically. The complex design required careful handling of multiple subcomponents and adapter plates, creating numerous opportunities for installation mistakes. Result: 50/50 chance of excessive leakage upon every startup. After switching to a simpler two-piece cartridge design with proper installation verification, one installation in March 2023 remained leak-free through February 2025. The install process dropped from hours of careful assembly to just one hour.

Flush System Verification for Power Plant Service

“There are very few streams harder to seal than hot water.” That insight from mechanical seal specialists on Eng-Tips reflects hard-won experience. Water lubricity decreases significantly above 80C (180F), making your flush system configuration critical for boiler feed pump service.

API Plan 11 – recirculating process fluid from pump discharge – is NOT suitable for 180F boiler feed water. The seal faces need cooling that Plan 11 cannot provide at these temperatures. API Plan 23 – a closed loop with heat exchanger – should always be installed for hot water service. Plan 23 keeps water cool at the seal faces through thermosyphon circulation, preventing vaporization and thermal shock.

Before installing any seal on a power plant pump, verify the flush system:

- Confirm the correct API plan for your service temperature

- Check tubing connections for blockages or restrictions

- Verify cooler operation and cooling water supply

- Target seal return line temperature below 130F (54C) for hot water applications

- Use 3/4″ tubing with large-radius bends to promote circulation

Never run a mechanical seal dry. As John Morton of the European Sealing Association and John Crane states: “Operating a conventional mechanical seal on air for even a few seconds can shorten the life of the seal or cause complete seal failure.” In power plant service, ensure your flush system is operational before pump startup, and verify flow during commissioning.

Ongoing Maintenance for Continuous Duty Operation

A German lignite-fired power plant demonstrated what structured maintenance achieves. Their 12 high-performance pumps and 60+ secondary pumps operated with mean time between repairs of just 20 months. After implementing upgraded seals combined with a structured verification and maintenance program, MTBF improved to 40 months – a 100% increase. Unplanned pump shutdowns were eliminated.

The difference was not just better seals. The structured program included:

- Pre-installation verification at every seal change

- Consistent installation procedures across maintenance teams

- Flush system verification during operation

- Documentation of seal performance for trend analysis

Manufacturer maintenance intervals typically assume general industrial service – perhaps 15,000 hours between overhauls. Power plant continuous duty demands more frequent verification. Do not wait for leakage to trigger inspection. Establish monitoring checkpoints:

- Weekly: Visual inspection for leakage, check flush system indicators

- Monthly: Verify cooler performance, check tubing for restrictions

- During any planned outage: Measure shaft runout, inspect seal chamber condition

Understanding why seals fail helps you target your maintenance program. Most failures in power plant service trace to thermal issues, installation problems, or flush system inadequacies – all preventable with proper verification.

Pre-Installation Verification Checklist

Every power plant seal installation should include these verification steps:

- Shaft Runout: Measure TIR at seal location. Accept: <0.002-0.005″ standard speed, <0.001-0.002″ for >3600 RPM. Reject and repair if exceeded.

- Seal Chamber Condition: Check face flatness (TIR <0.005″), surface finish (32 rms on shaft contact areas), and inspect for corrosion or damage.

- Alignment Verification: Confirm pump/motor alignment within 0.001-0.002″ before seal installation. Document readings.

- Flush System Check: Verify correct API plan for service temperature, confirm tubing is clear, test cooler operation, ensure cooling water supply.

- Component Inspection: Examine seal faces for scratches or damage, verify correct seal configuration for your application, confirm all O-rings and gaskets are present and undamaged.

The time spent on pre-installation verification is measured in minutes. The time lost to a premature seal failure in power plant service is measured in days of emergency repairs, lost generation revenue, and repeat part costs. Investment in verification pays returns every time a seal runs to its full design life.

Start your next seal installation with this checklist. Document your findings. Build verification into your standard procedure. The goal is not perfection on paper – it is seals that run reliably for years rather than months.