Liquid

The chemical properties of the liquid, such as pH level, corrosiveness, and reactivity, will determine the compatibility of the seal material.

For example, if you’re pumping highly corrosive chemicals, you may need a seal made of a chemically resistant material like Hastelloy or titanium. On the other hand, if you’re dealing with clean fluids, a standard carbon or ceramic seal may suffice.

Pressure

Seals are designed to withstand specific pressure ranges.

High-pressure applications may require specialized seal designs, such as balanced seals or metal bellows seals, which are capable of handling extreme pressures while maintaining a stable seal face contact.

Temperature

Seals must be able to withstand the operating temperatures of the system without experiencing thermal expansion, contraction, or degradation.

High-temperature applications may require seals made of materials with high thermal stability, such as graphite, silicon carbide, or tungsten carbide.

In addition to the steady-state operating temperature, it’s crucial to consider any temperature fluctuations that may occur during start-up, shutdown, or process upsets. Rapid temperature changes can cause thermal shock, leading to seal face cracking or distortion.

Viscosity

High-viscosity liquids, such as heavy oils or polymers, can create a thicker fluid film between the seal faces, leading to increased leakage and reduced seal life. In these cases, a seal with a higher closing force or a narrower seal face may be required to maintain adequate sealing.

Low-viscosity liquids may not provide sufficient lubrication between the seal faces, leading to increased wear and heat generation. In such applications, a seal with a lower closing force or a wider seal face may be necessary to promote fluid film formation and reduce friction.

Solids Content/Abrasives

Abrasive particles can cause excessive wear on the seal faces, leading to increased leakage and premature seal failure. In these cases, a seal with harder, more wear-resistant face materials, such as tungsten carbide or silicon carbide, may be necessary to withstand the abrasive environment.

Shaft Size

Seal manufacturers typically offer seals in a range of standard sizes to accommodate common shaft diameters, but custom seals can also be designed for unique or non-standard shaft sizes.

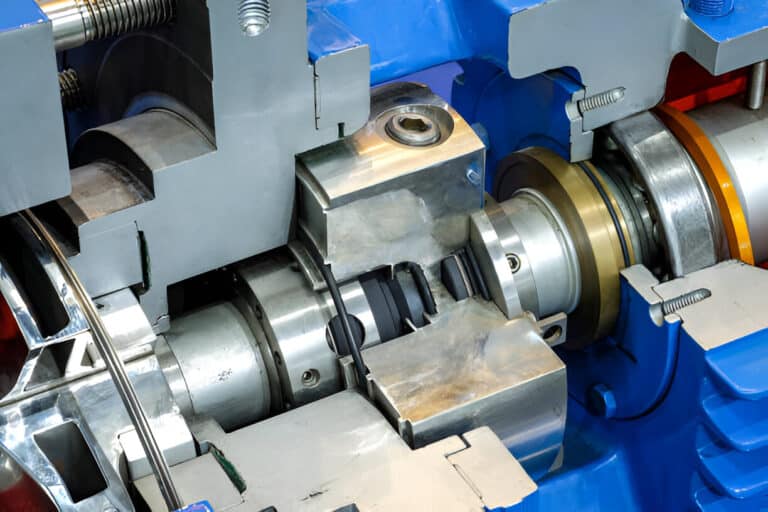

When considering shaft size, it’s also important to account for any shaft movement or misalignment that may occur during operation. Radial shaft movement can cause the seal faces to open or close, leading to increased leakage or seal face damage. To accommodate shaft movement, a seal with a more flexible design, such as a bellows or a spring-loaded seal, may be necessary to maintain consistent seal face contact.

Equipment Type

Different types of pumps, such as centrifugal, positive displacement, or submersible pumps, may require specific seal designs to accommodate their unique operating characteristics and installation requirements.

For example, centrifugal pumps typically use a standard cartridge seal or a component seal, which can be easily installed and replaced without disassembling the pump. Positive displacement pumps, on the other hand, may require a more specialized seal design, such as a split seal or a cartridge seal with a separate gland, to accommodate the higher pressures and unique shaft geometries associated with these pumps.

Environmental Concerns

When selecting a seal for a specific environment, it’s important to consider any regulatory or safety requirements that may apply. For example, in the food and beverage industry, seals must comply with FDA and USDA regulations for food-grade materials and sanitary design. In the oil and gas industry, seals must meet stringent safety and performance standards to prevent leakage and ensure environmental protection.